Backing plates for sputtering targets

A technology of backing plate and sputtering target, which is applied in the field of backing plate for sputtering target, which can solve the problems of increased cost, failure to prevent cracking of brazing material, insufficient combination of target and backing plate, etc., to reduce cracking , save the effect of leveling treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

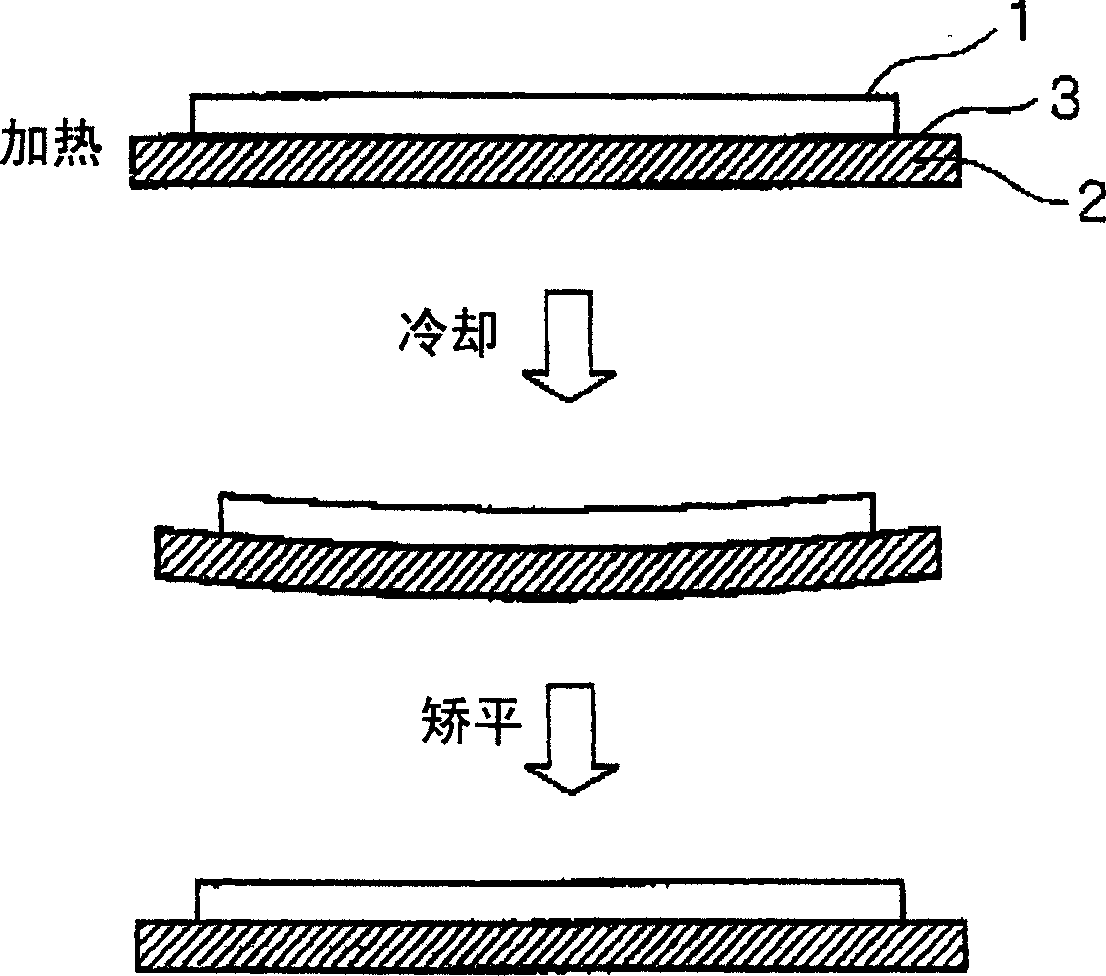

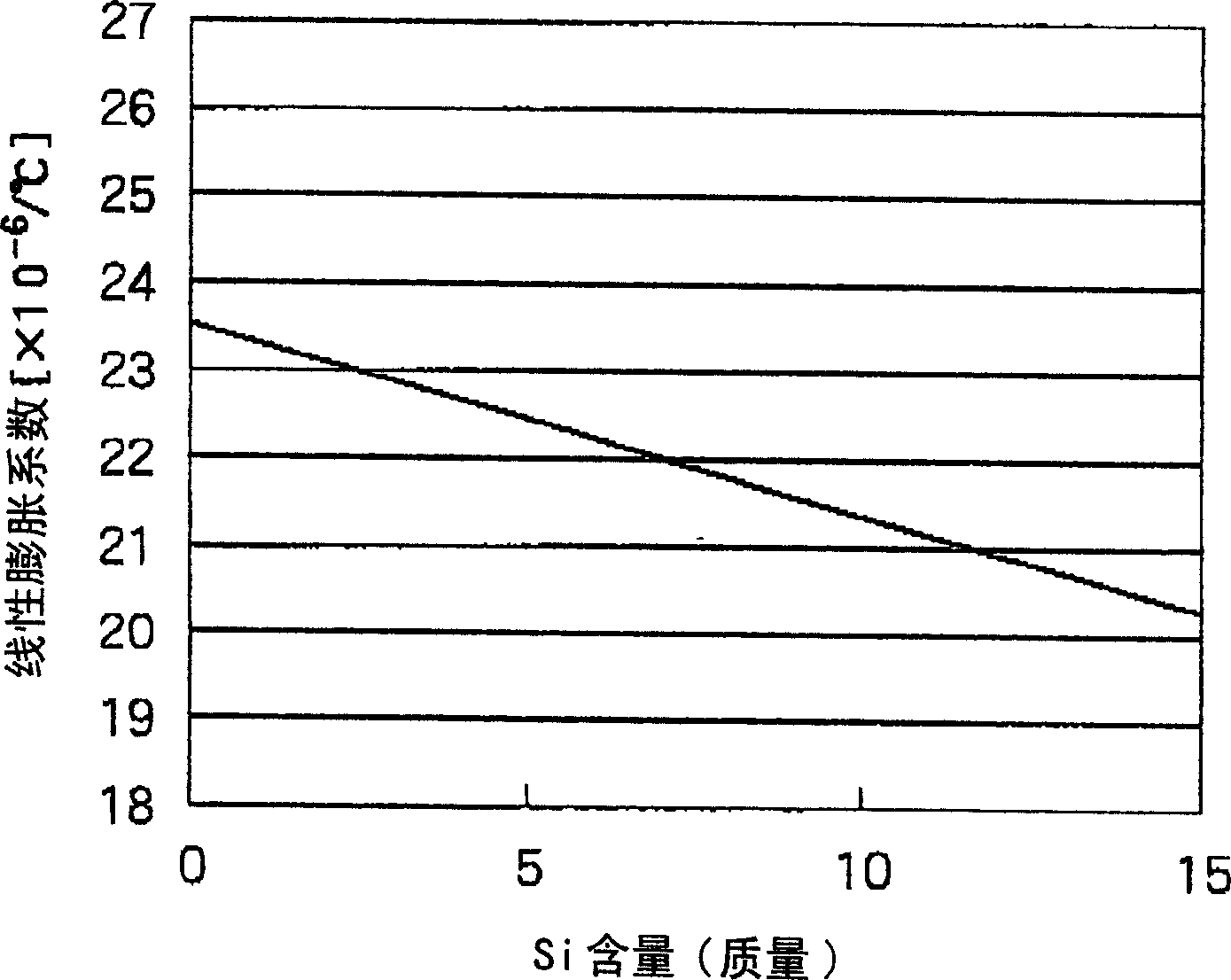

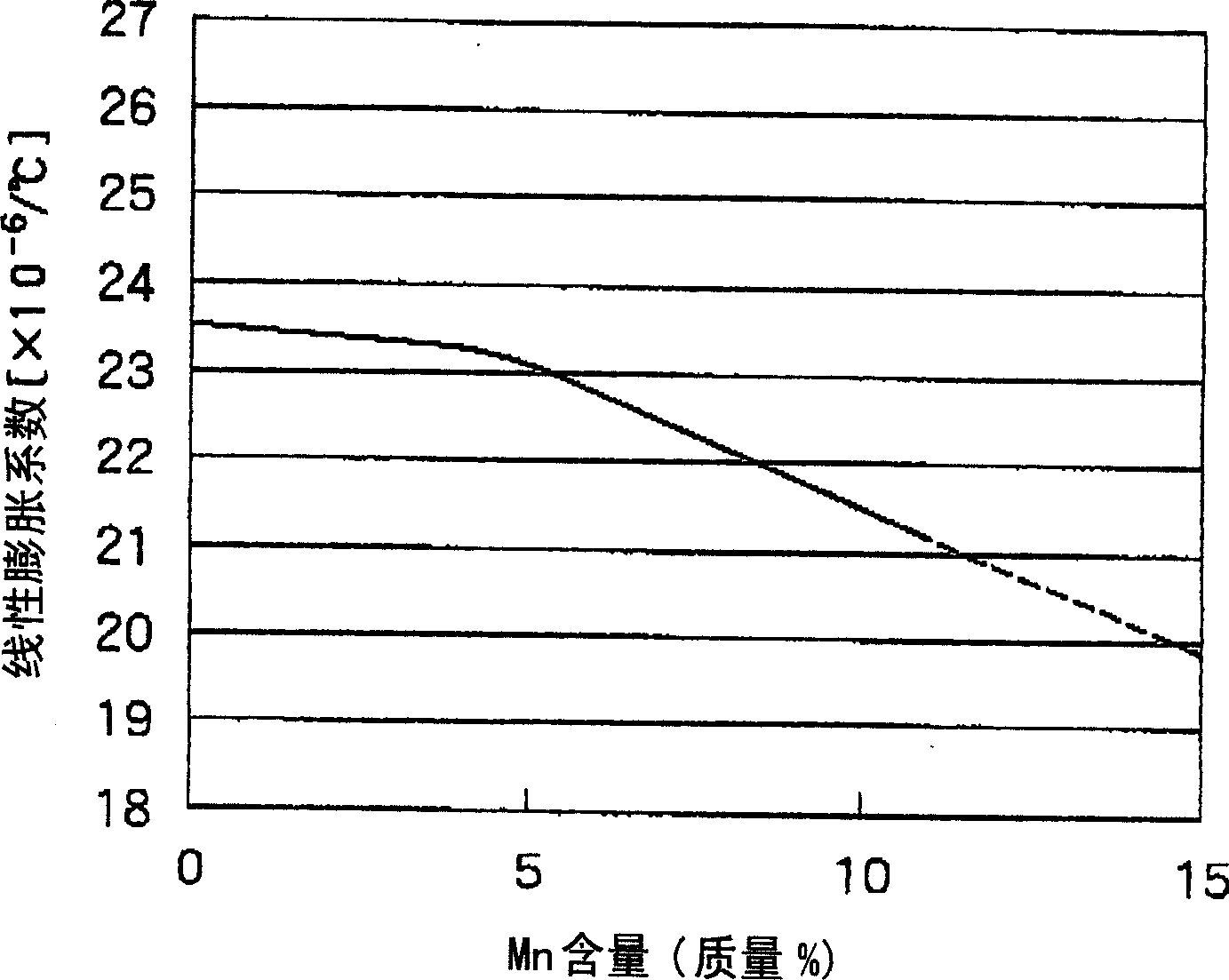

[0021] The inventors of the present invention conducted exhaustive studies on a backing plate for sputtering targets that reduces warpage occurring when bonding to the target and film deposition (sputtering) of Al-Nd alloy thin films. Stress, eliminating the leveling of warpage, reducing the cracking of the brazing solder placed between the target and the backing plate caused by repeated warpage formation and leveling, and thus enabling stable film deposition operations over a long period of time . In particular, they conducted exhaustive studies on backing plates for sputtering targets that reduce warpage, thereby allowing even targets containing Al alloys characterized by relatively low linear expansion coefficients such as Al- In the case of Nd, Al-Ti and Al-Ta alloys, or metals such as Mo, Ta and Ti, leveling is also omitted and film deposition can be repeated.

[0022] Therefore, they found that the optimal backing plate for sputtering targets contained an average linear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com