Method for producing non-fry potato food

A technology of non-fried potato preparation and production method, applied in the field of food processing, can solve the problems of inability to achieve healthy food, fried potato chips cause cancer, etc., and achieve the effects of retaining flavor and taste, promoting transformation, and eliminating hidden dangers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

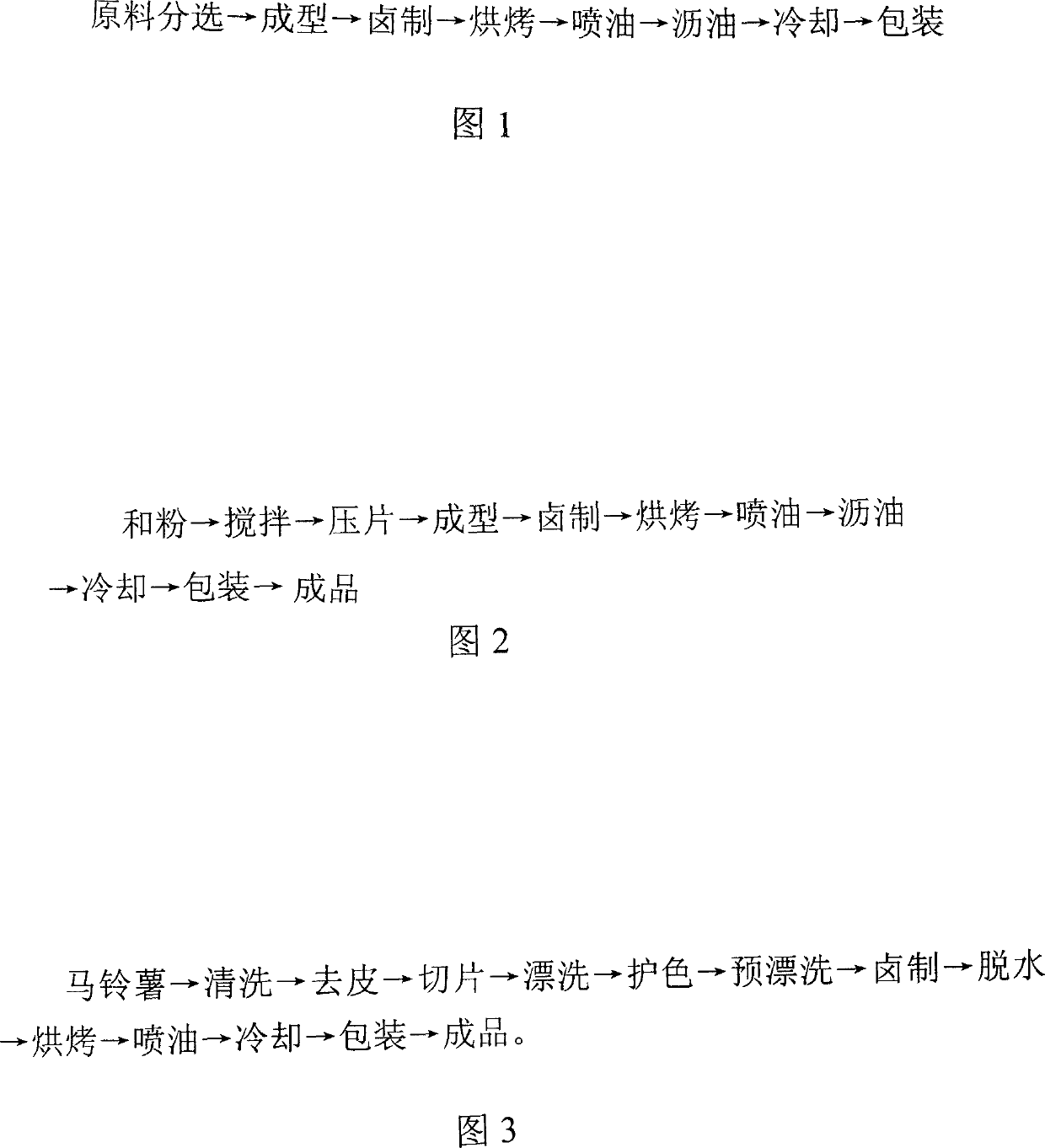

[0011] This embodiment illustrates the method by taking the preparation of composite potato chips as an example. Referring to Fig. 1, in the present embodiment, raw material sorting, molding are:

[0012] A. Kneading powder: Fully mix powder materials such as potato powder, starch, modified starch, granule powder, trace additives, seasonings, etc. with liquid materials such as emulsifier, syrup, water, vegetable oil, etc. to form a dough;

[0013] B. Sheeting: Use a roller to press the spread dough into a dough sheet. The surface of the roller is required to maintain a certain range of low temperature to prevent the formation of a film on the surface of the dough sheet and cause large bubbles during baking;

[0014] C. Forming: Use a mold to cut the dough pieces formed by calendering into the dough pieces of the required shape for production, and the waste materials are recycled through the conveyor belt, crushed and then added to the kneading machine for reuse;

[0015] The ...

Embodiment 2

[0026] This embodiment illustrates the method by taking the preparation of fresh-cut potato chips as an example. The preparation of other potato chips such as sweet potatoes and sweet potatoes is roughly the same. Referring to Figure 2, raw material sorting and molding are as follows:

[0027] A. Raw material requirements: The tubers are required to be neat in shape, uniform in size, thin in skin, shallow and few in bud eyes, high in starch and total solids, low in reducing sugar, no more than 2%-3%;

[0028] B. Cleaning and washing: Pour the potatoes into the feed port, pick up rotten potatoes, stones, gravel, etc. on the conveyor belt, and then send them into the washing machine through the lifting bucket for cleaning;

[0029] C. Peeling: A large number of mechanical peeling is used. After peeling, the surface of the potato pieces is smooth and to prevent waste caused by excessive peeling. After peeling, they are washed and sent to the conveyor to pick out the unclean pota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com