Spinning preparation machine and cover for extension device therefor

A drafting device and preparation machine technology, applied to spinning machines, continuous winding spinning machines, drafting equipment, etc., can solve problems such as unreasonable energy consumption, achieve less energy and cost consumption, and prevent heat The effect of moving in, preventing the loss of cooldown potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

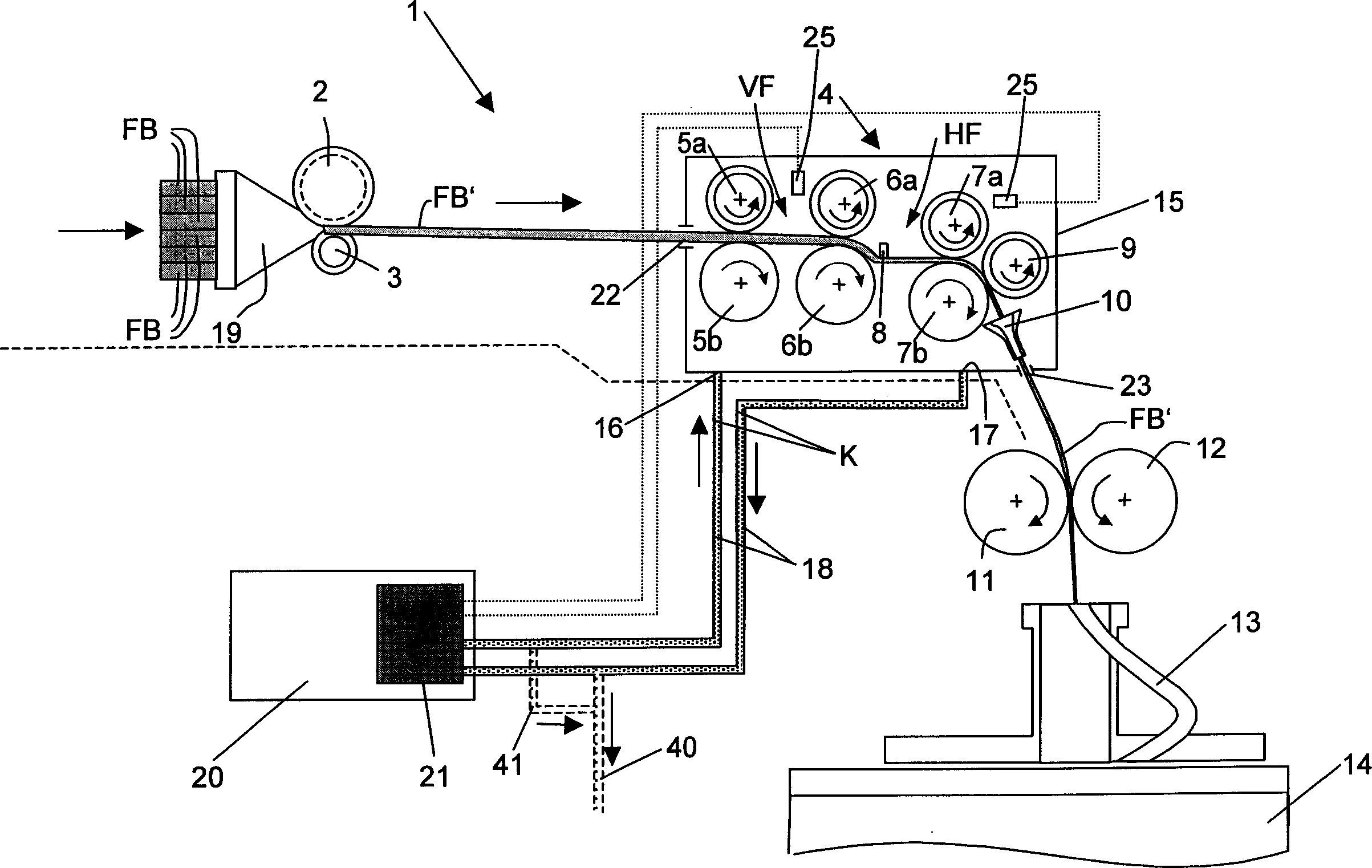

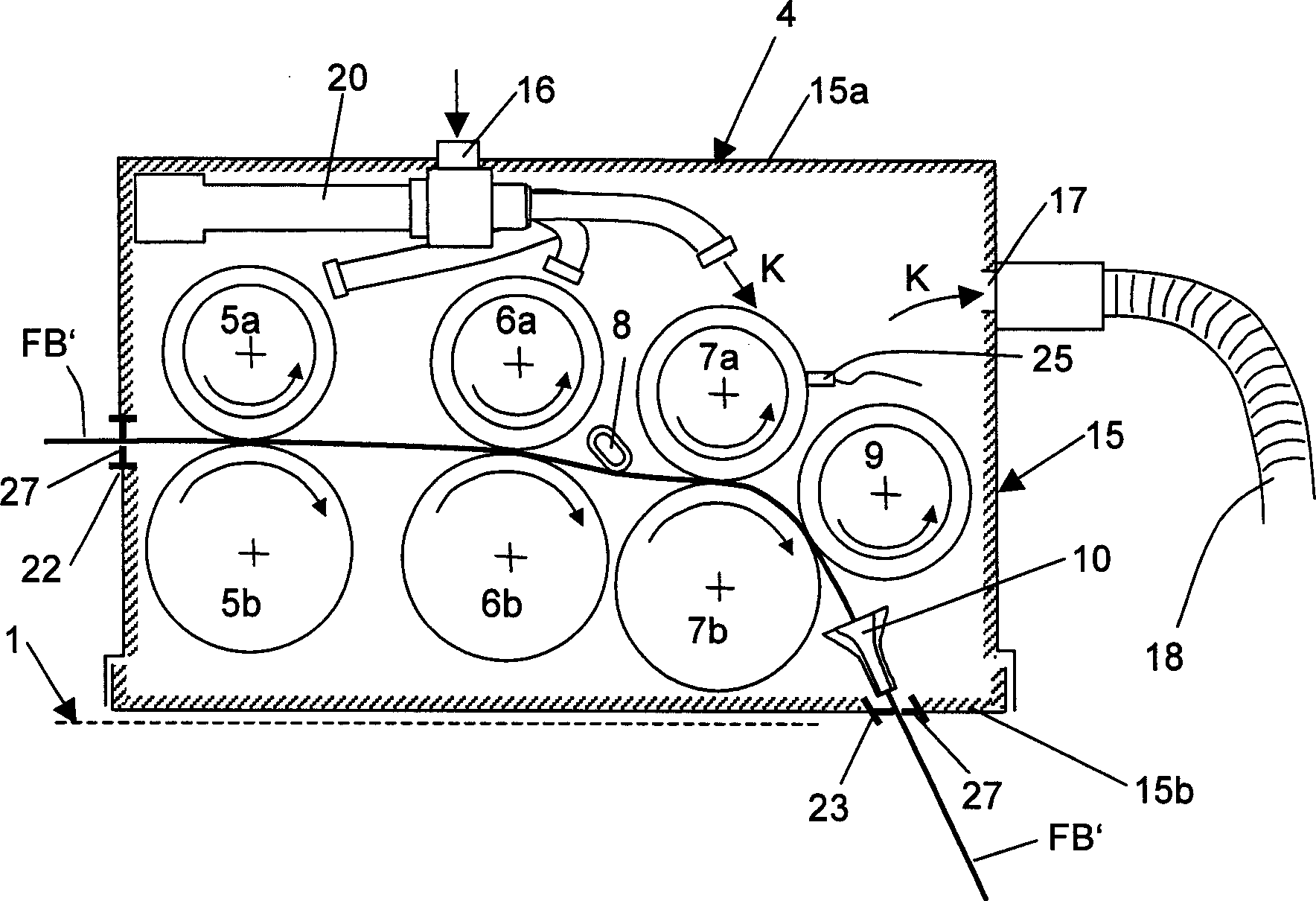

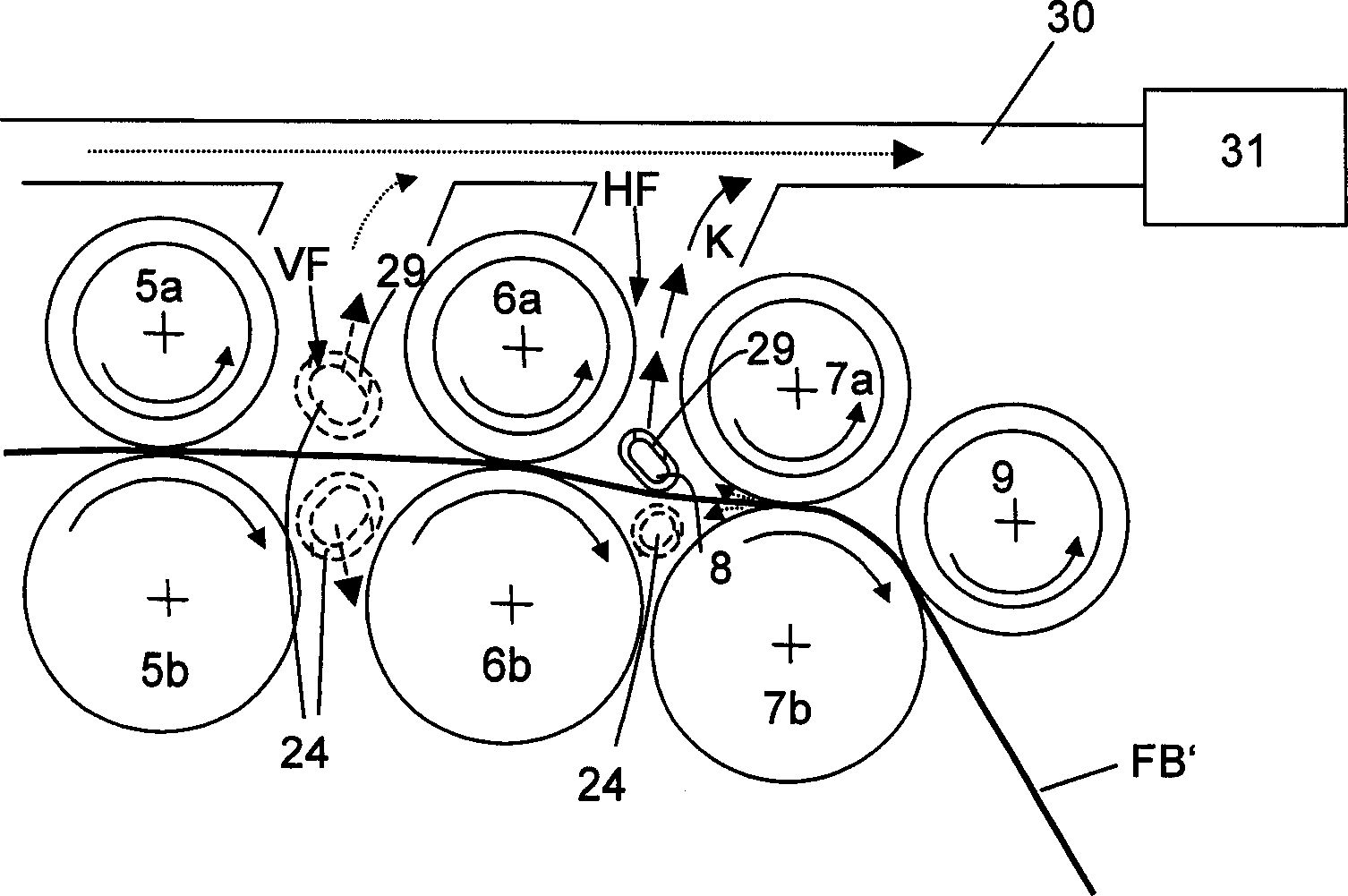

[0043] figure 1 Shown in the schematic cross-section is the drafting device of the spinning preparation machine 1 as an example. According to this example, one or more fiber strips FB are placed side by side in the drafting operation. For clarity, these straps are shown in top view. A compression device 19 for compressing the fiber strip FB is arranged at the beginning of the drafting device. After running through a mechanical scanning device 2, 3, the compressed fiber ribbon FB' consisting of the original several fiber ribbons FB is introduced into the drafting device 4, which builds the core of the drafting. Typically, the drafting device 4 has three traction elements, usually pairs of rollers, between which the traction is generated. These said three pairs of rollers are the pair of inlet rollers 5a, 5b, the pair of intermediate rollers 6a, 6b and the pair of output (or transfer) rollers 7a, 7b. In the order given, each pair provides increasing rotational speed. Via th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com