Material disperser

A batching machine and material technology, applied in mixers, mixers with rotary stirring devices, dissolving and other directions, can solve the problems of inability to adjust particle thickness, rapid wear of rotors and stators, and high operating costs, and achieve stable and uniform production results. The effect of improving industrial production efficiency and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

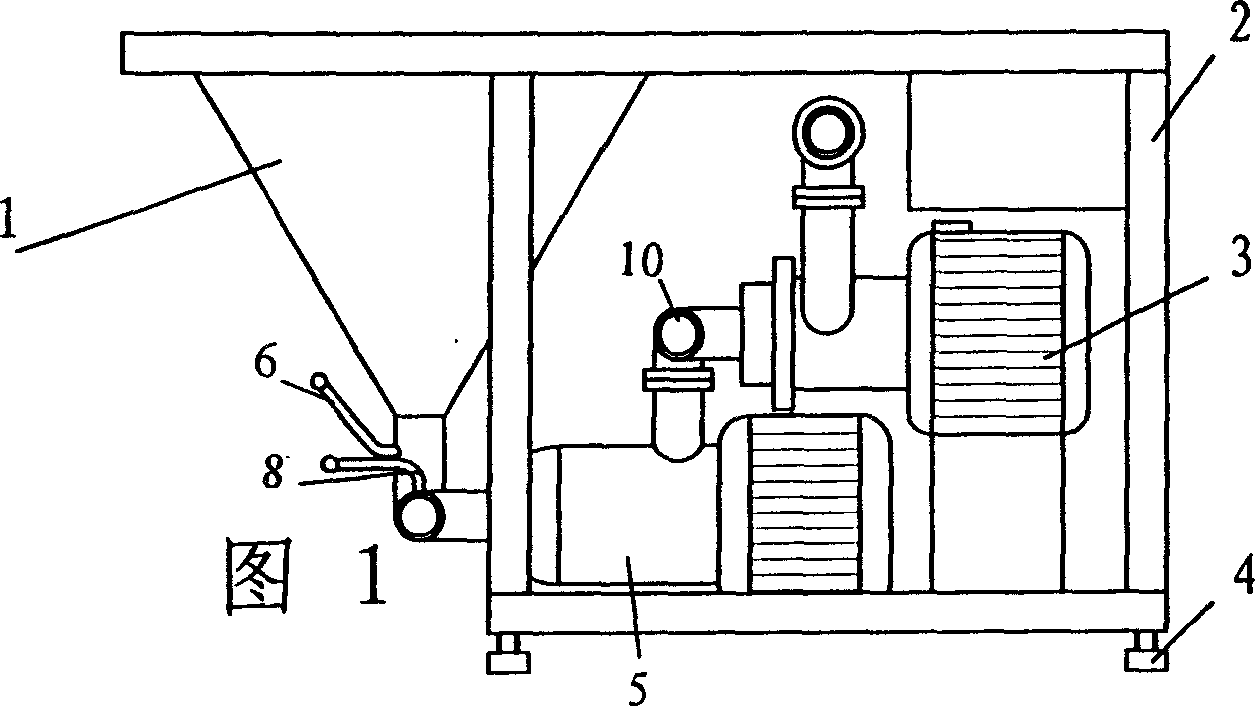

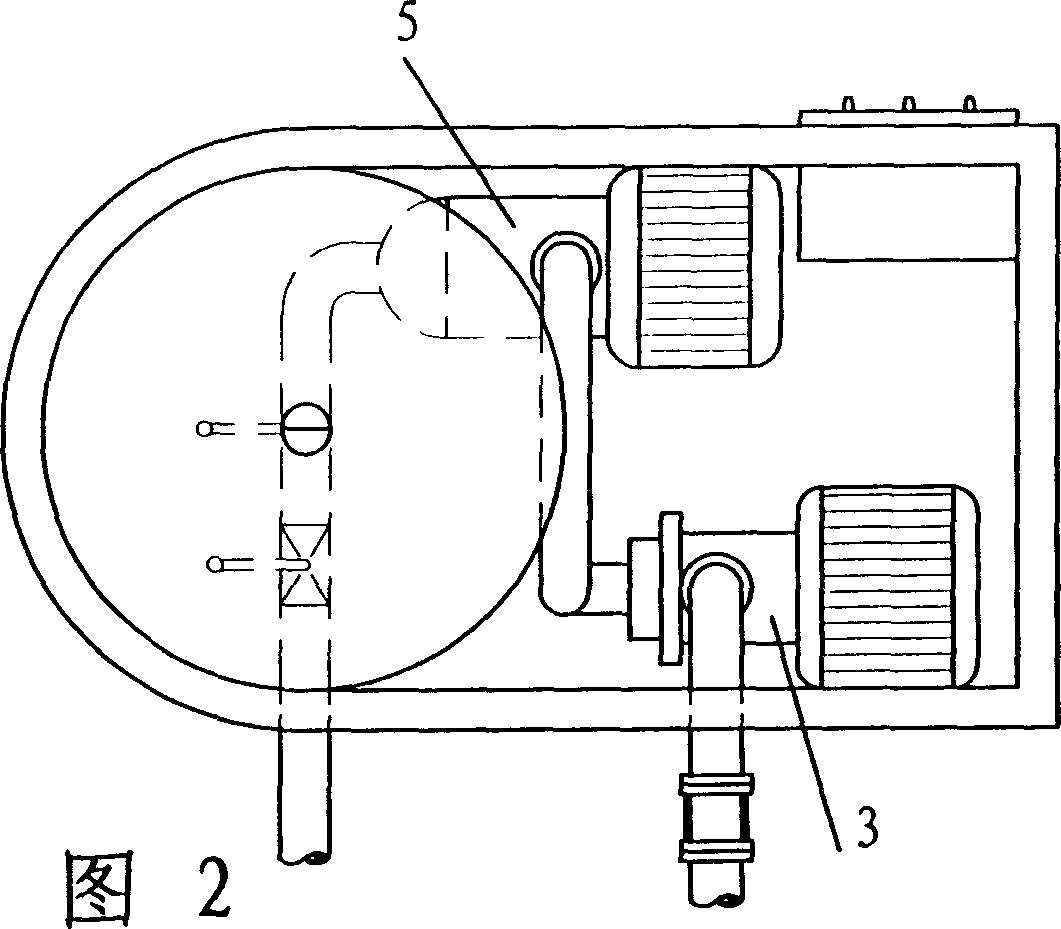

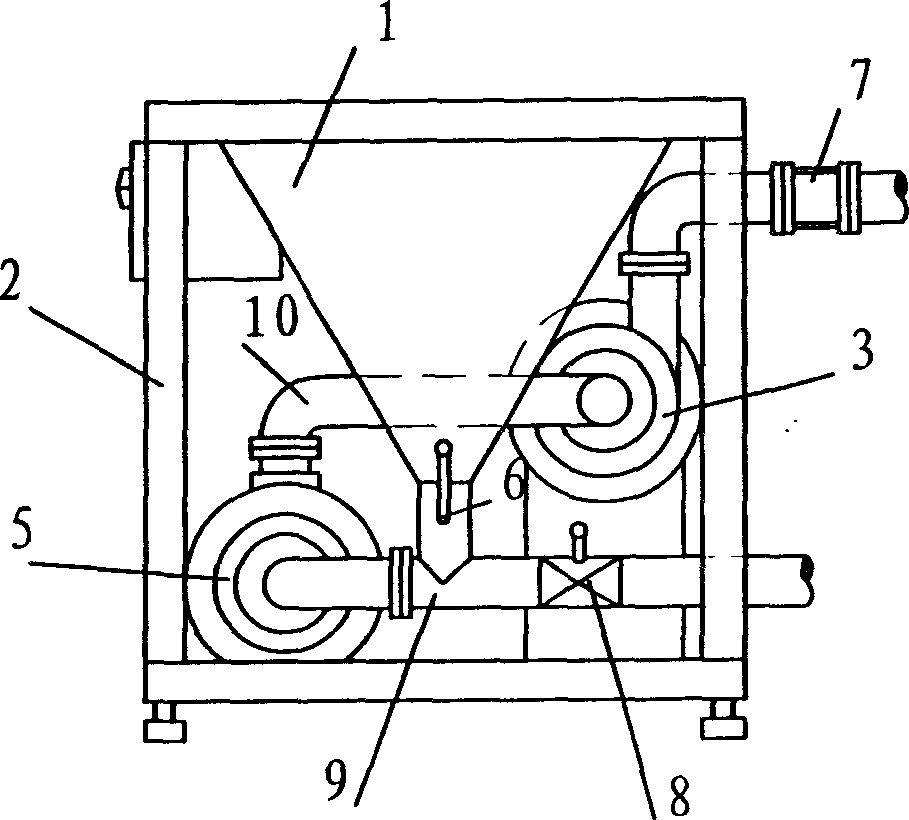

[0035] See Figure 1, Figure 2 and image 3 , the material batching machine of the present invention comprises a cabinet 2, a self-priming pump 5 driven by a motor installed at the bottom of the cabinet, and a pump connected to the feed pipe 9 of the self-priming pump and fixedly installed on the top surface of the cabinet 2 The solid hopper 1 is connected to the self-priming pump 5 through the channel 10, and the motor-driven mixing and crushing device 3 is provided with control valves 6 and 8 at the outlet of the solid hopper 1 and the inlet of the self-priming pump, respectively.

[0036] The self-priming pump is a self-priming sanitary delivery pump (commercially available), which is an important part of the machine and provides power for the solid material system, especially in the production of high-viscosity material products, the self-priming pump with strong suction Pumps are indispensable. The self-priming pump ensures the correct flow direction of the liquid and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com