Balance-spring variable frequency series mechanical timer travel time system

A mechanical timer and hairspring technology, applied to mechanically driven clocks, mechanisms for stabilizing frequency, mechanisms for adjusting frequency, etc., can solve the problems of serving customers and not being able to supply on demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with embodiment and accompanying drawing, the present invention will be further described.

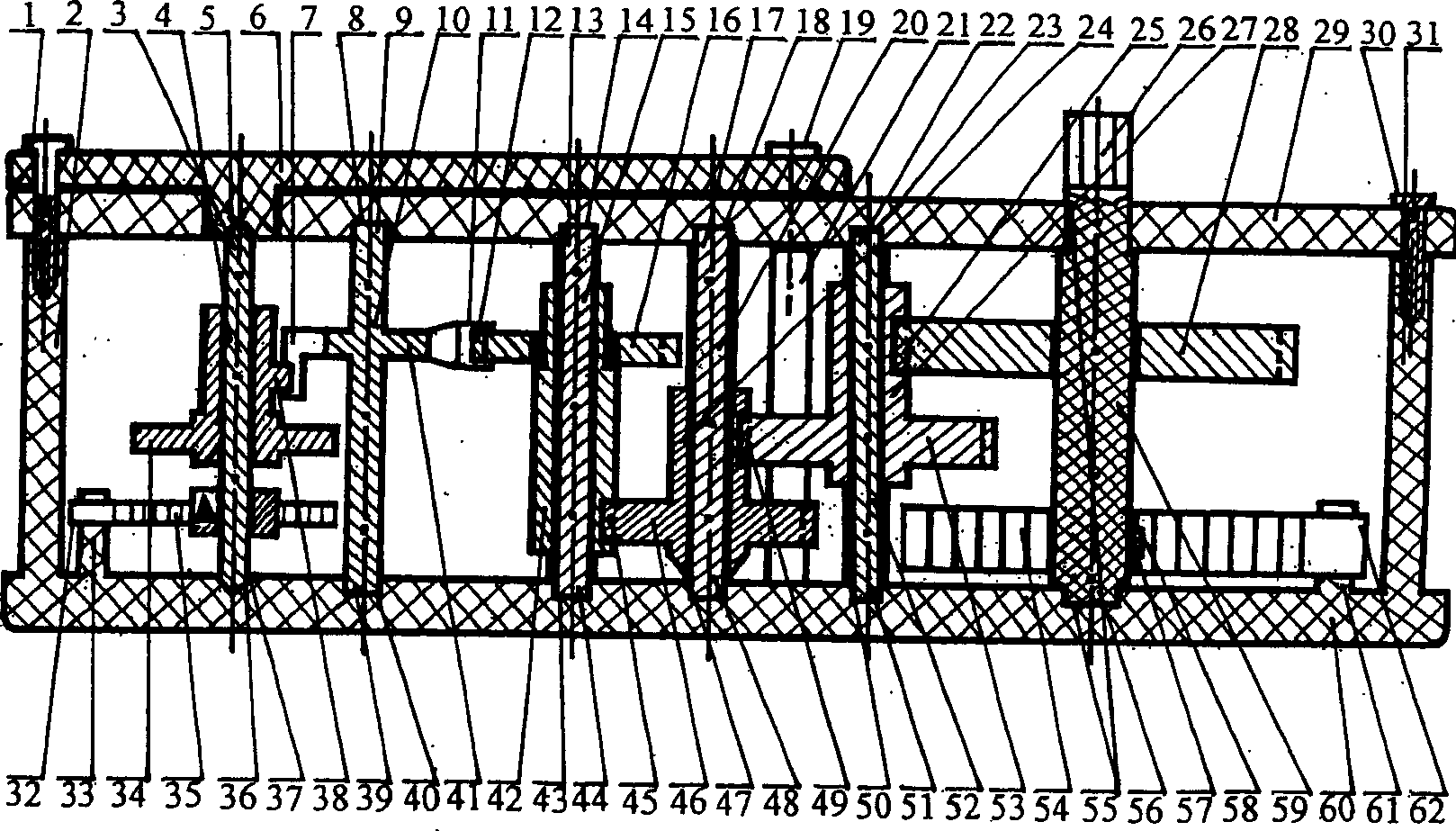

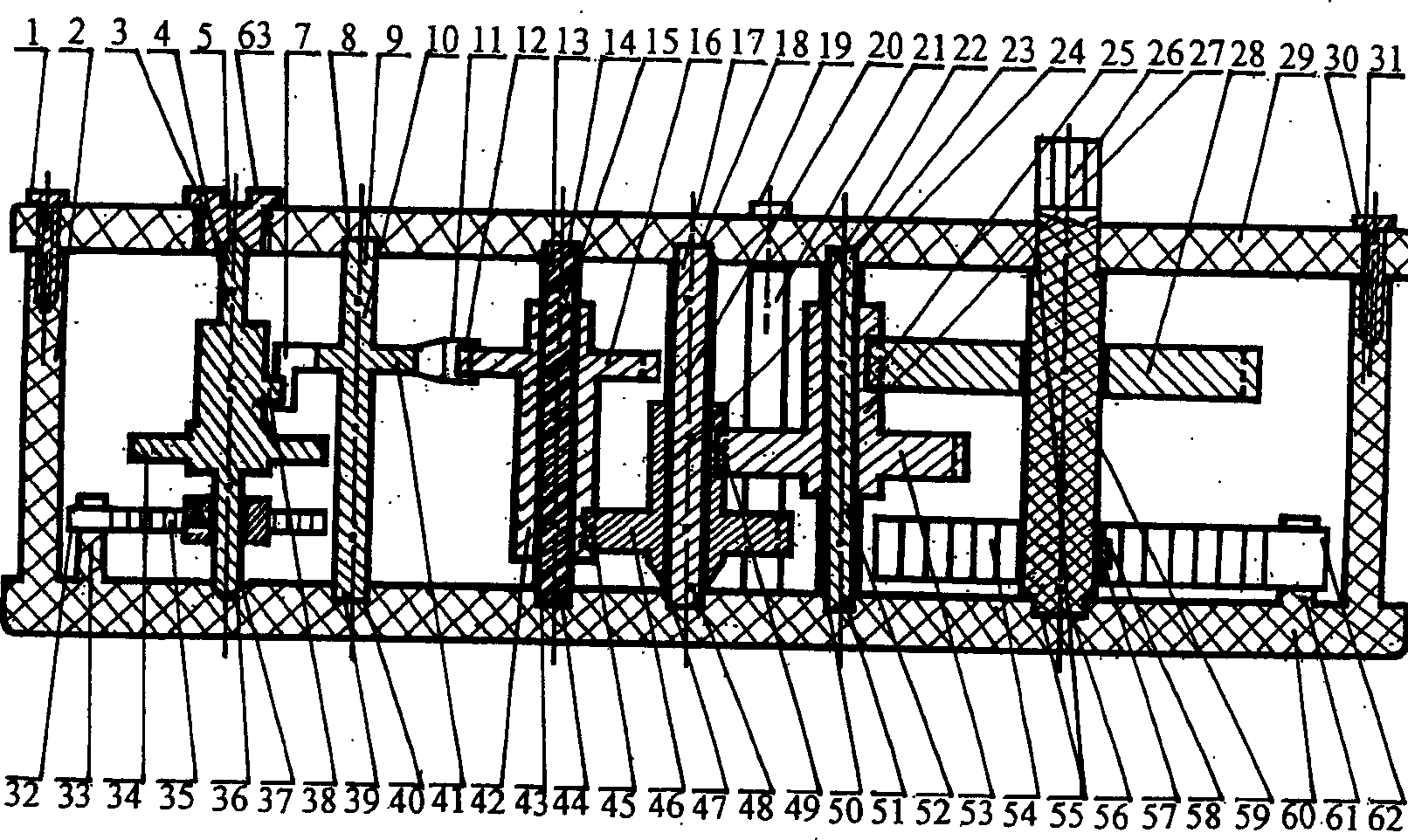

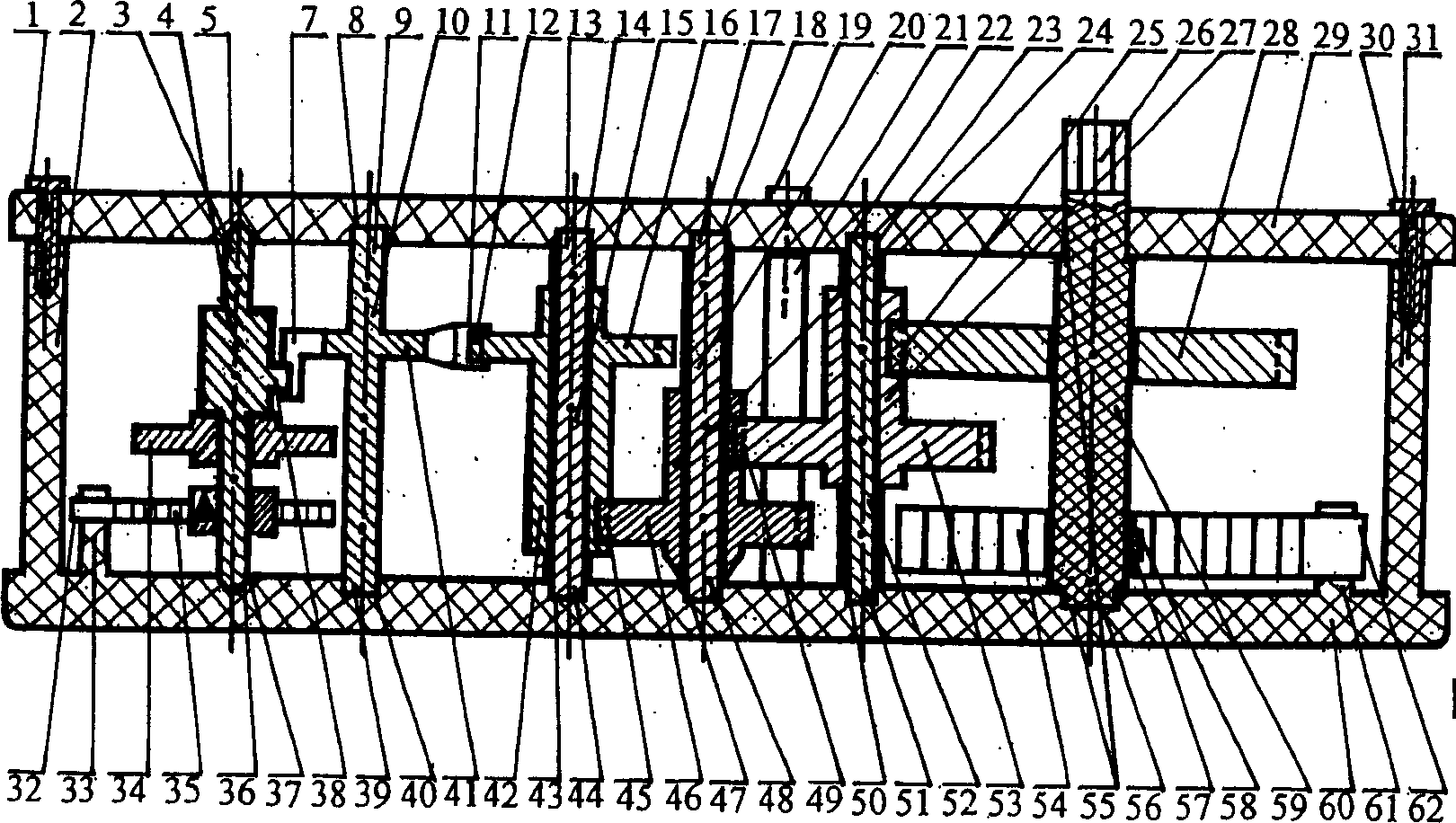

[0014] Such as figure 1 Shown, pass through and synchronously mechanically connect the head gear 28 with the shaft end 26 by the head wheel shaft 59 and send out 56 hooks 57 with the shaft end to insert the head wheel formed by the spring 54 and the inner end 58 of the spring, and the two wheel shafts 52 are formed by the shaft end. End 22 or 51 passes through two small gears 27 and two large gears 53 that are connected to each other, and the three wheel shafts 20 pass through three small gears 24 and three large gears 46 that are connected to each other with shaft ends 17 or 48. The finished three wheels, the final wheel shaft 15 pass through the final gear 42 and the escape wheel 16 formed by the mutual synchronous mechanical connection with the shaft end 13 or 44, the teeth 12 of the escape wheel, the upper clamping plate 29, the lower clamping plate 60, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com