Automatic navigation lock and water way channel

A ship lock and automatic technology, applied in ship locks, ship lifting devices, water conservancy projects, etc., can solve the problems of slow passing speed, unusable, low ferry efficiency, etc. The effect of a large volume of transport

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

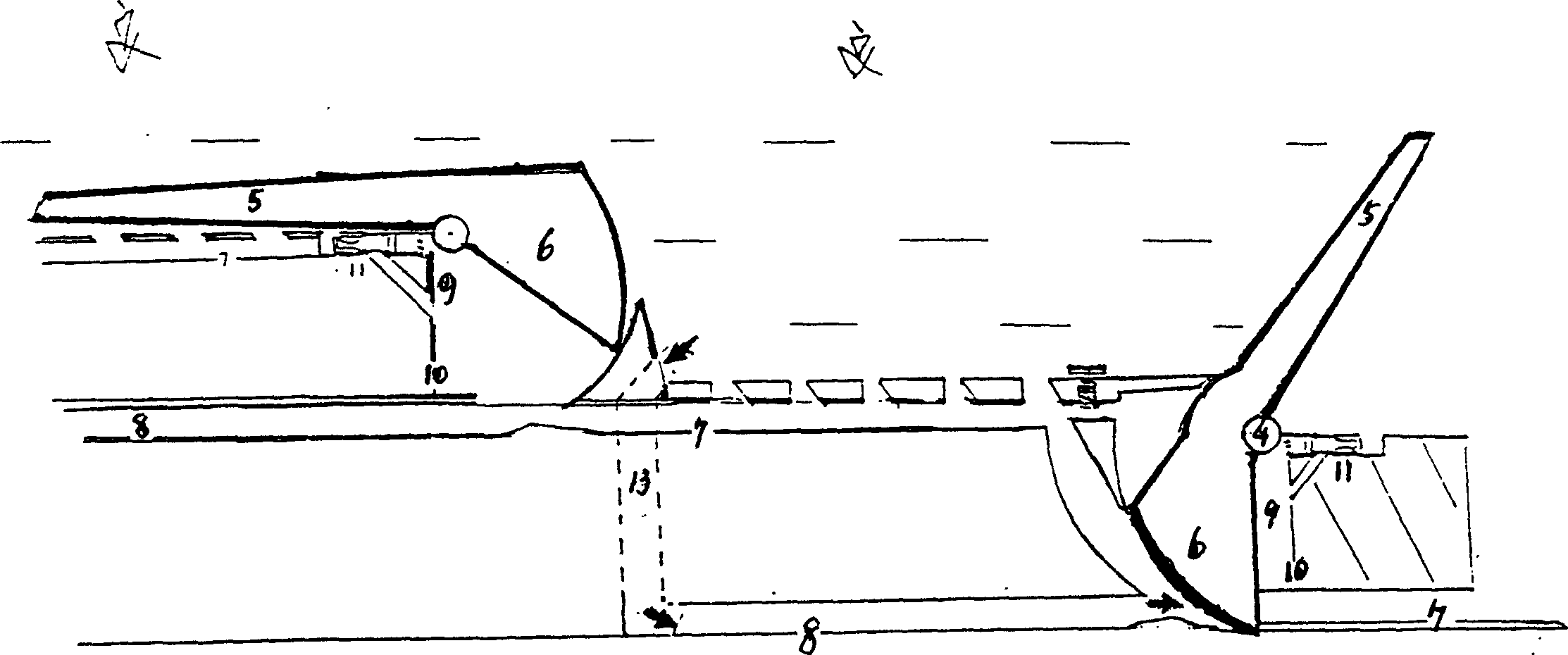

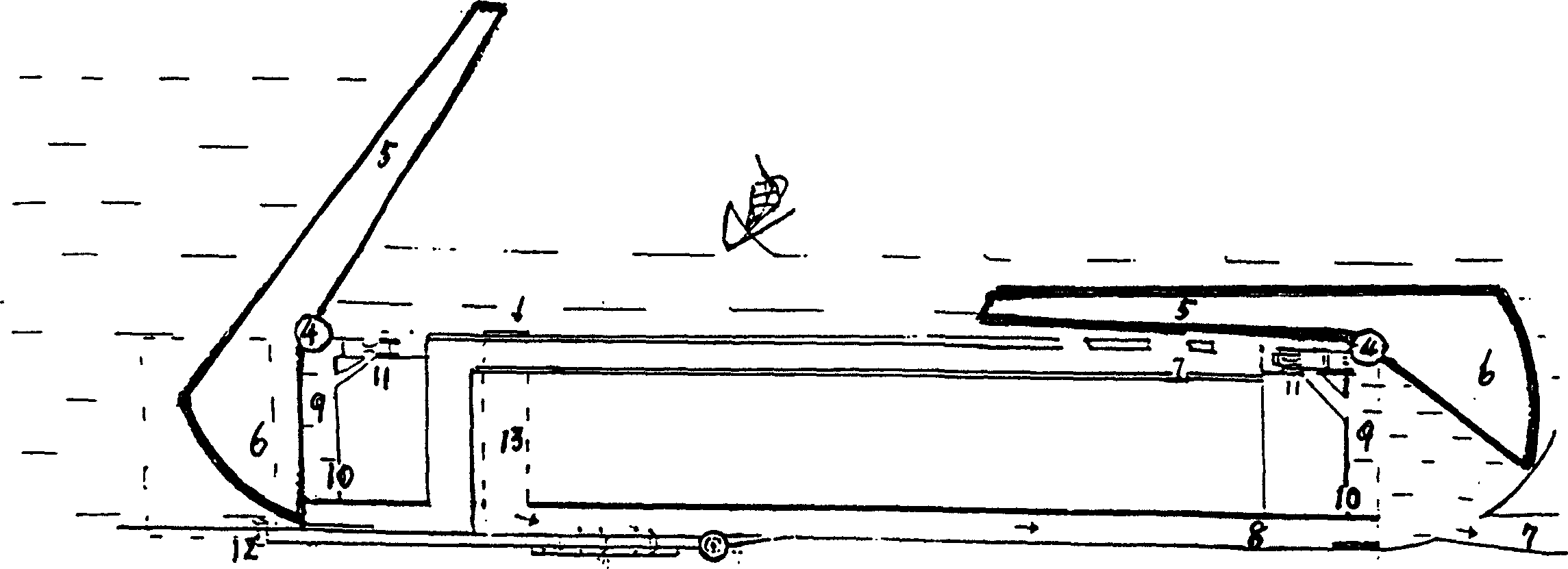

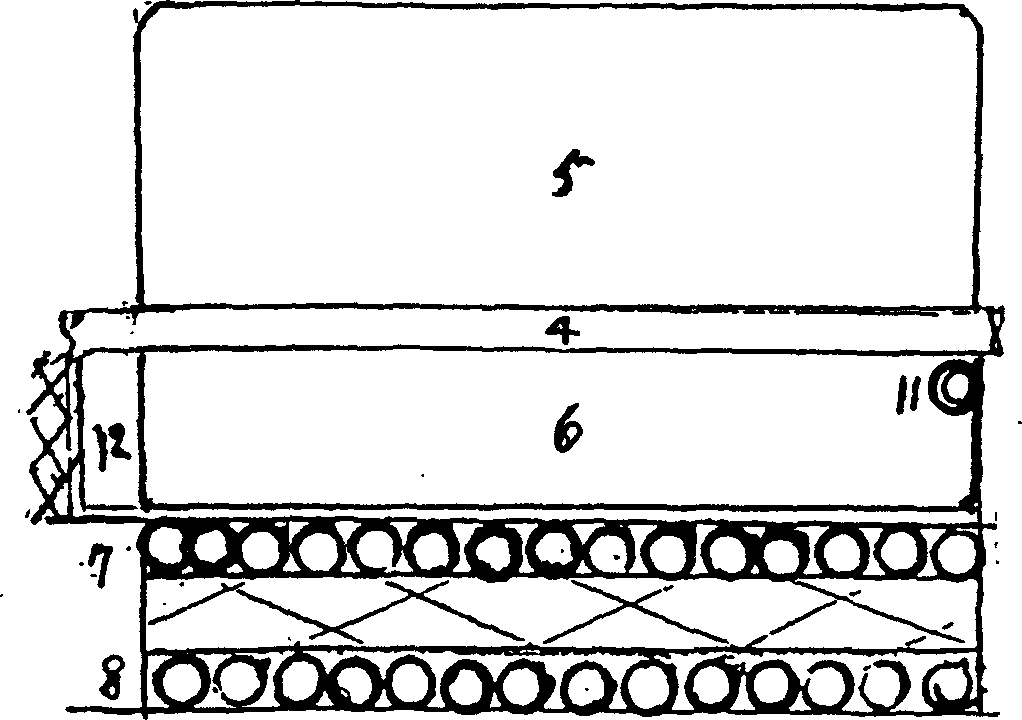

[0028] Such as Figure 4 As shown, the ship lock has a water grab 1 in the water channel at the back gate of the ship lock chamber, and at the same time, there is a covert channel 2 on the bottom plate. The ship has passed the first gate, and now the position of the middle lock chamber is preparing to enter the second gate. room, such as figure 2 It is a schematic diagram of the position of some ship locks when the ship is running in the channel. As shown in the figure, the upper gate 5 and the lower gate 6 are integrated and installed on the horizontal shaft 4. The lower gate 6 and the floor lip wall 10 are combined to form a hydraulic reaction chamber. 9. The water pressure reaction chamber 9 is connected to the infrared induction water pressure tee piston 11. There is a lower flushing and discharging channel 8 of the upper lock chamber under the hydraulic reaction chamber 9, and the lower flushing and discharging channel 8 is horizontally connected to the upper flushing and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com