Method for Making scintillator layer for x-ray detector, scintillator layer

A scintillator and detector technology, which is applied in chemical instruments and methods, X-ray/infrared technology, radiation intensity measurement, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

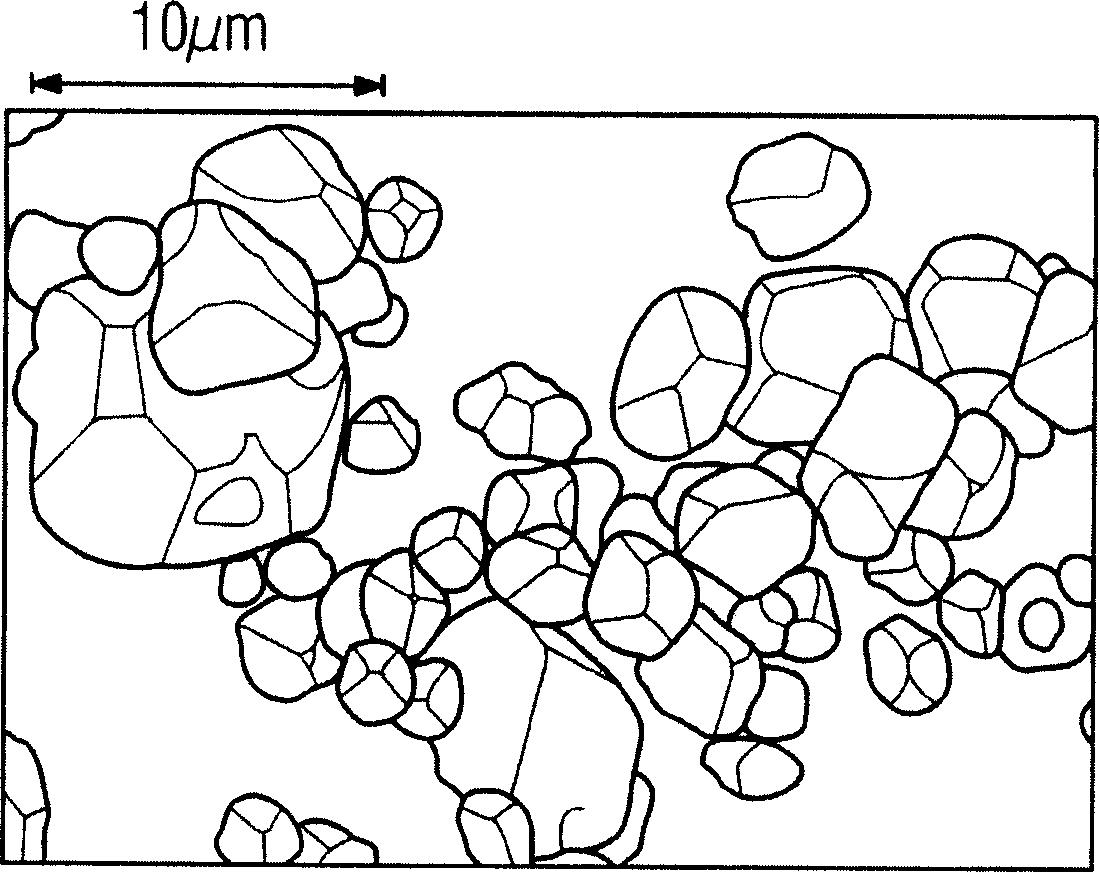

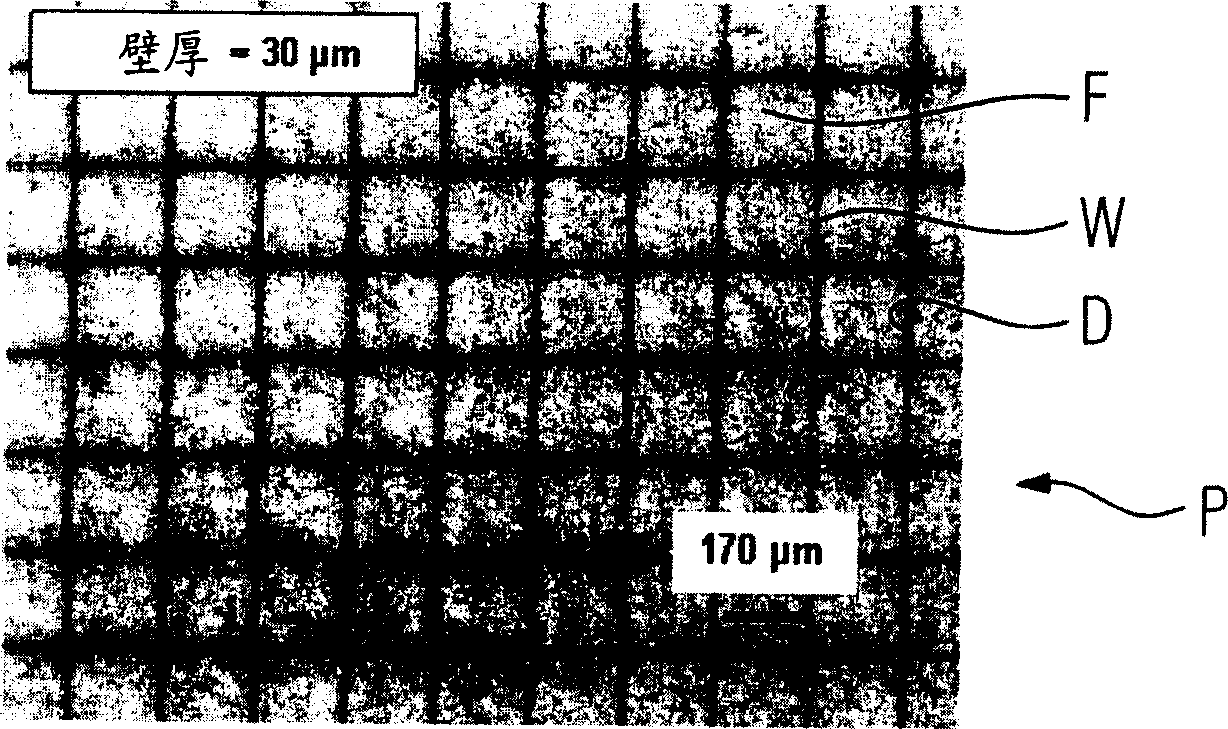

[0028] for manufacturing figure 2 The first scintillator layer shown uses a plastic plate P made of epoxy resin. The plastic plate P has a thickness of 2 mm and external dimensions of 20×20 mm. Punch D is basically square. Its open area has an edge length of approximately 170×170 μm. The perforations D are separated from each other by a wall W, the wall thickness of which is about 30 μm. The production of such a plastic sheet P takes place in a conventional manner, for example by means of stereolithography. For the manufacture of filler F for example using figure 1 Gd shown 2 o 2 S phosphor. Such as figure 1 As shown, the Gd 2 o 2 The maximum particle diameter of the S phosphor is about 10 μm. (Merck) Paraffin wax is liquid at 80 to 100°C, and Gd with an average particle size of about 21nm is added 2 o 2 S phosphor. Here, the quantity ratio in filler F is set such that Gd 2 o 2 The S phosphor accounts for about 70% by mass, and the paraffin wax accounts for ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com