Al-zn-mg-cu alloy

An aluminum alloy product and alloy technology, applied in the field of wrought aluminum-zinc-magnesium-copper aluminum type, to achieve the effect of easy recycling capacity and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

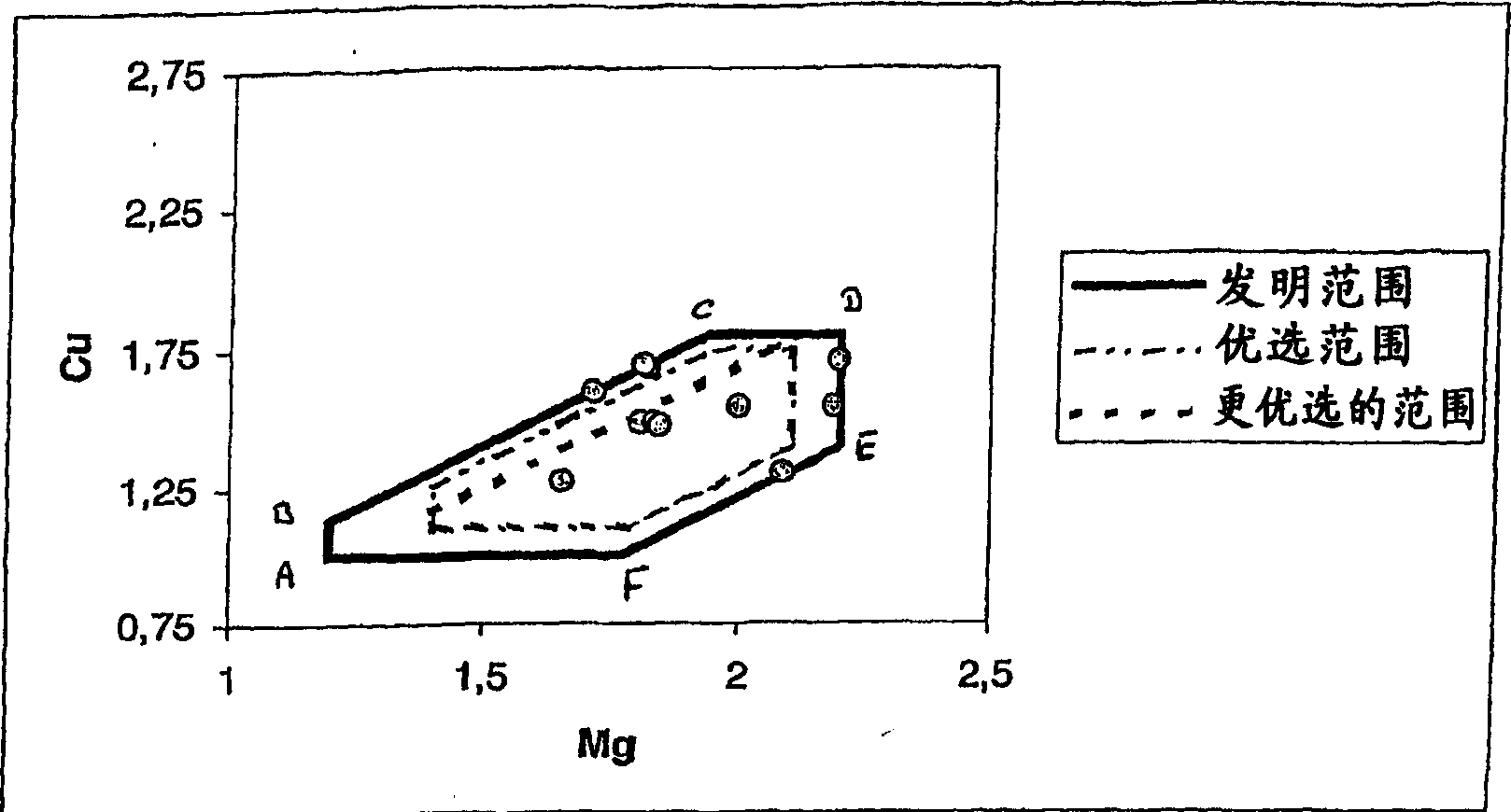

Method used

Image

Examples

Embodiment Construction

[0048] The design of commercial aircraft requires different types of structural components with different combinations of properties. However, when an alloy is processed into different product forms (that is, sheet, plate, thick plate, forging or extruded profiles, etc.) and used in multiple structural components, where the component has different load sequences during its service life and The alloy must therefore be extremely versatile in order to meet the different material requirements of all these product forms.

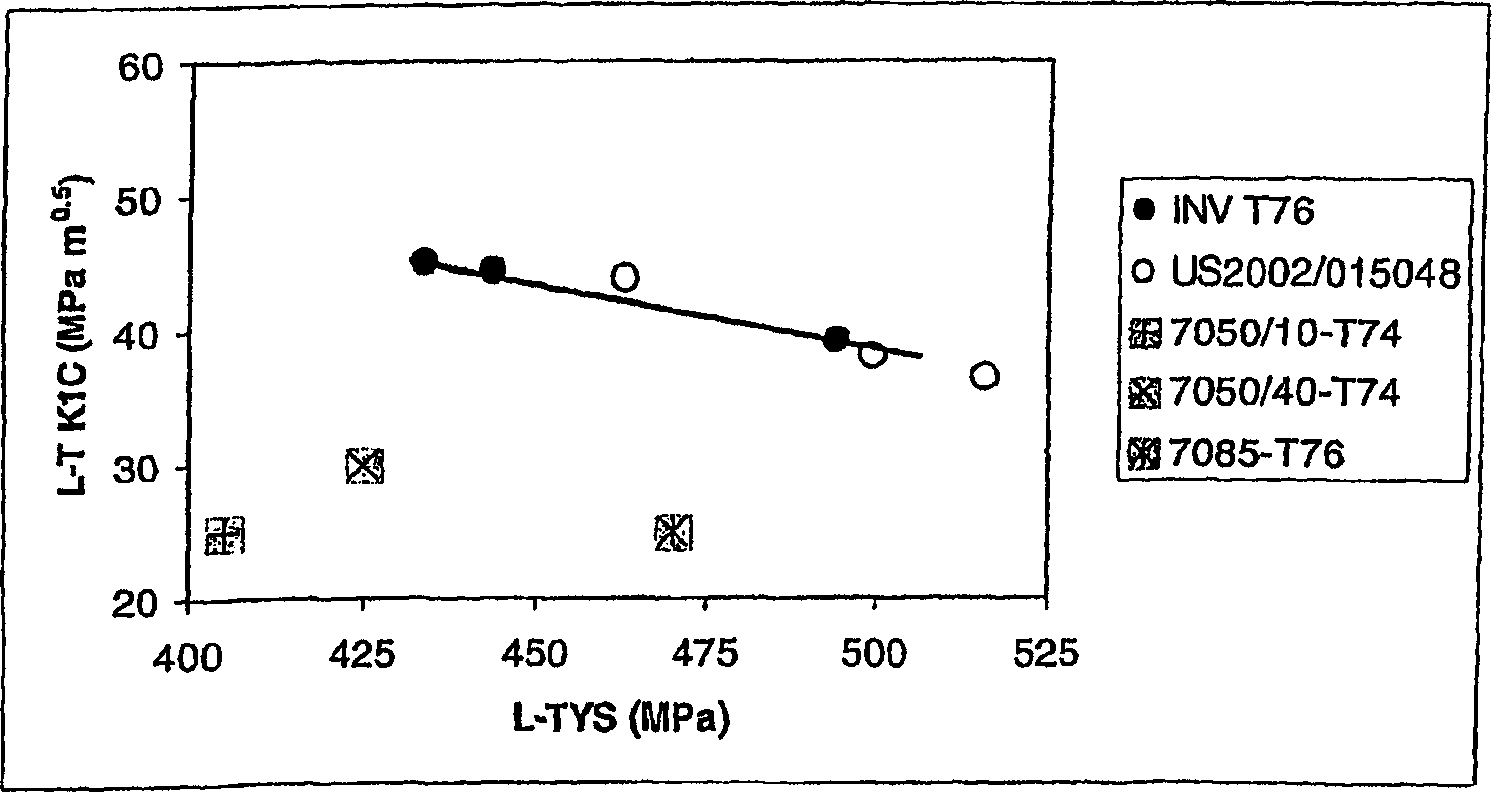

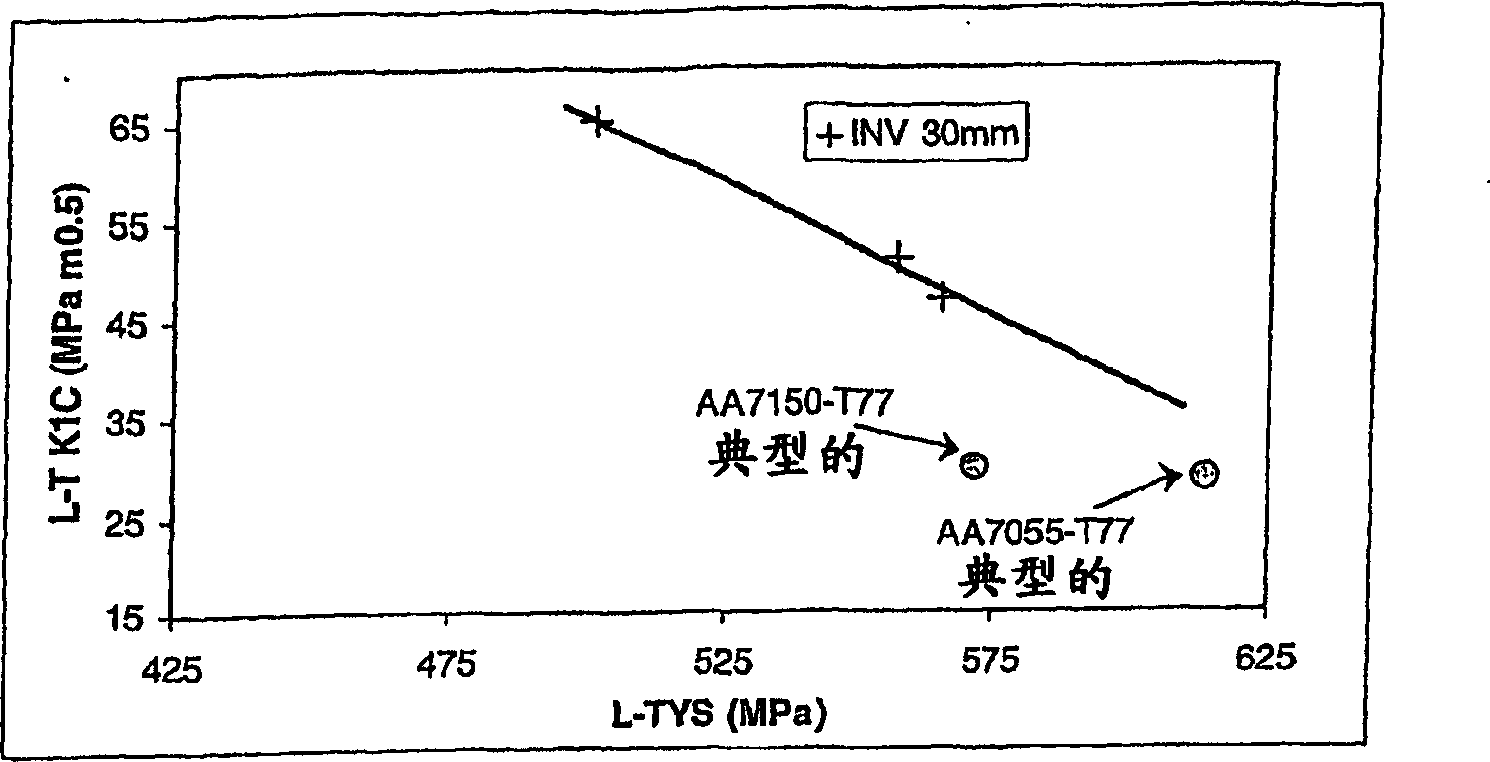

[0049] Important properties of materials for fuselage sheet products are failure tolerance properties under tensile loading (ie: FCGR, fracture toughness and corrosion resistance).

[0050] For the lower wing skins of large commercial jets, the material's critical properties are similar to those required for fuselage sheets, but higher tensile strength is specifically desired by aircraft manufacturers. In addition, fatigue life is also a major material property....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com