Adsorption filter

An adsorption filter and filter technology, applied in the direction of membrane filter, filtration separation, dispersed particle filtration, etc., can solve the problems of expensive, complex filter structure, and no advantage in material cost and manufacturing cost, etc., and achieve the goal of reducing odor Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

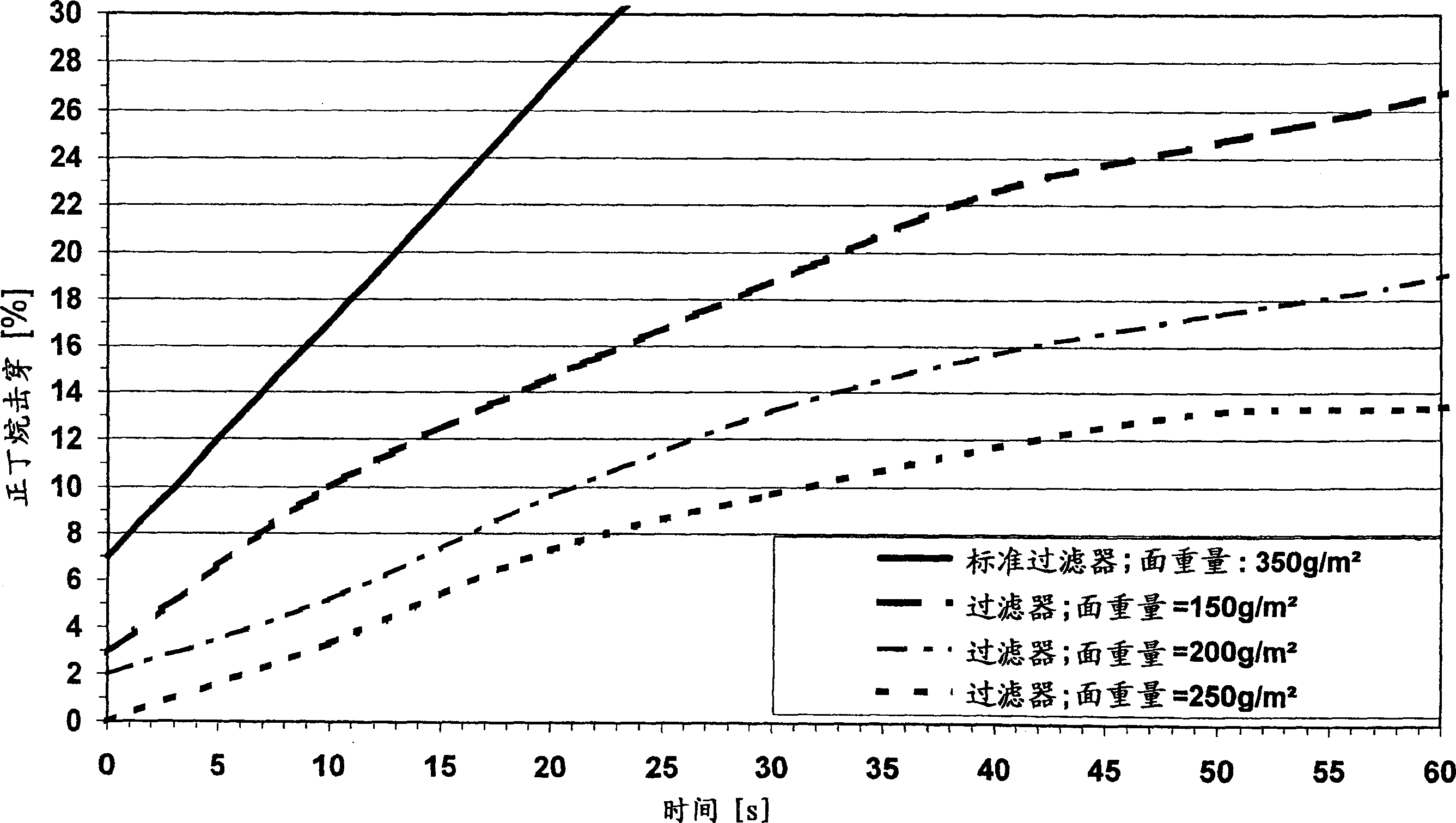

[0031]The n-butane breakdown was determined for three composite filters with adsorption filters with different amounts of activated carbon and a standard commercially available composite filter. The filter is designed as a known pleated filter with a zigzag-folded filter medium, which is surrounded by a frame. All filters are made of non-woven fabric.

[0032] Filter manufacturing is biased and it should be taken into account here that the actual amount of activated carbon applied may differ from the theoretical value by 20g / m 2 . , the fraction of activated carbon particles whose size is below a specified particle size can deviate from the theoretical value by 10%.

[0033] Measurements are carried out in accordance with the gas adsorption standard DIN 71460-2 for automotive interior filters.

[0034] The specific structure of the filter is as follows:

[0035] The combined filter section has a single layer particle filter made of polypropylene (PP). The surface weight o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com