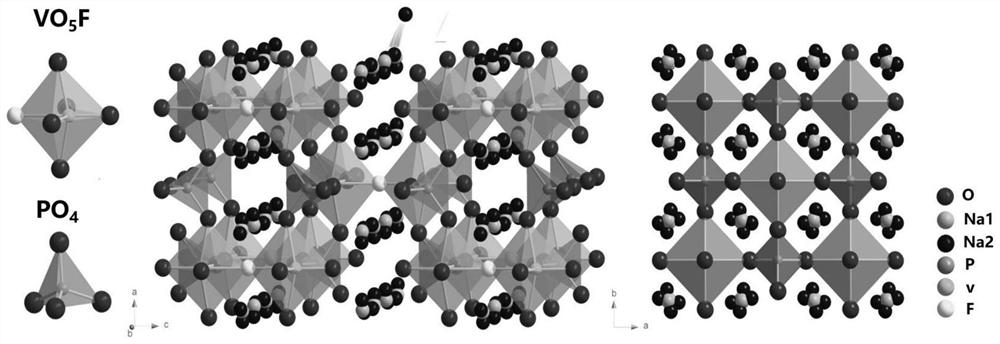

Preparation method and application of sodium vanadium oxyfluorophosphate/graphene composite electrode material

The technology of sodium vanadyl fluorophosphate and sodium vanadyl phosphate is applied in the field of high-energy electrochemistry, and can solve the problems of adsorption capacity effect, electrode oxidation, and common ion efficiency affecting charge efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Preparation of sodium vanadyl fluorophosphate / graphene material:

[0043] (1) Weigh ammonium dihydrogen phosphate, ammonium vanadate, sodium carbonate, and sodium fluoride to be 0.46g, 0.468g, 0.212g, and 0.084g, respectively, and add them to 8mL with a concentration of 4g L -1 A stable solution A is formed in the graphene solution;

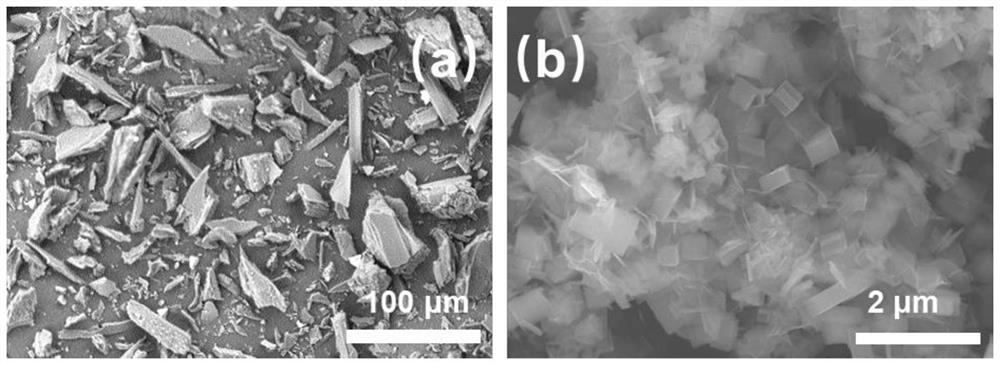

[0044] (2) Put the solution A obtained in step (1) on a magnetic stirrer, add 40 mL of N,N-dimethylformamide dropwise, adjust the pH to 7 with nitric acid, and then transfer it to a hydrothermal kettle. After heating for 10 hours, the obtained product was washed with deionized water and ethanol, and dried in a vacuum oven to obtain a black powder that was sodium fluorovanadyl phosphate / graphene composite material. The SEM image of the target product sodium vanadyl fluorophosphate / graphene material figure 1 (b) shown. The SEM image of the purchased activated carbon is as follows figure 1 As shown in (a): It is obvious that the size leve...

Embodiment 2

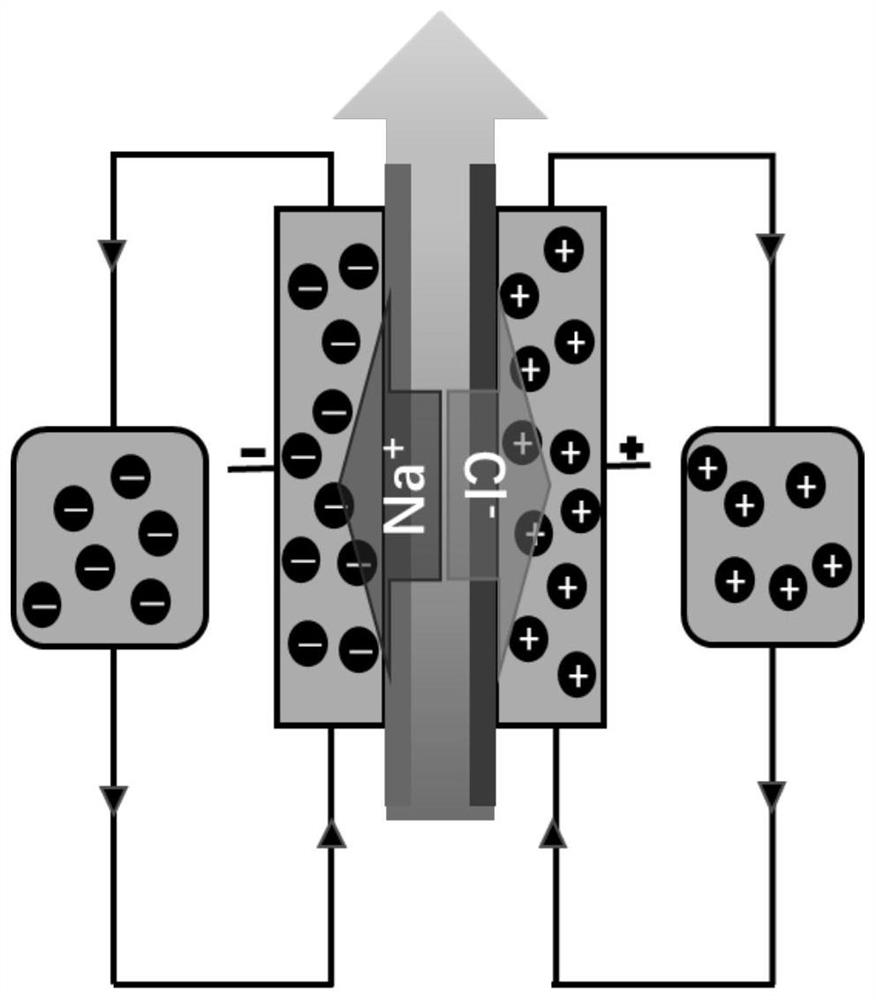

[0046] Application of sodium vanadyl fluorophosphate / graphene composite in flow electrode capacitive deionization technology.

[0047] Preparation of sodium vanadyl fluorophosphate / graphene electrode and activated carbon flow electrode:

[0048] After grinding the sodium vanadyl fluorophosphate / graphene composite material prepared in Example 1, mix it with carbon black at a mass ratio of 8:1, add it to a 1 g / L NaCl solution and stir for about 6-12 hours A uniformly mixed flow electrode slurry is obtained; the preparation method of the activated carbon electrode is similar to the above, and the sodium vanadyl fluorophosphate / graphene can be replaced by the purchased activated carbon.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com