mesoporous sio 2 Preparation method of surface-initiated boron affinity imprinted polymer material and its application in extraction of shikimic acid

An imprinted polymer and surface-initiated technology, which is applied in the preparation of organic compounds, chemical instruments and methods, and carboxylate preparation, etc., can solve the problems that the single-weight recognition ability of imprinted polymers is difficult to achieve deep separation and purification, and the composition is complex. , to achieve effective separation, increase adsorption efficiency, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

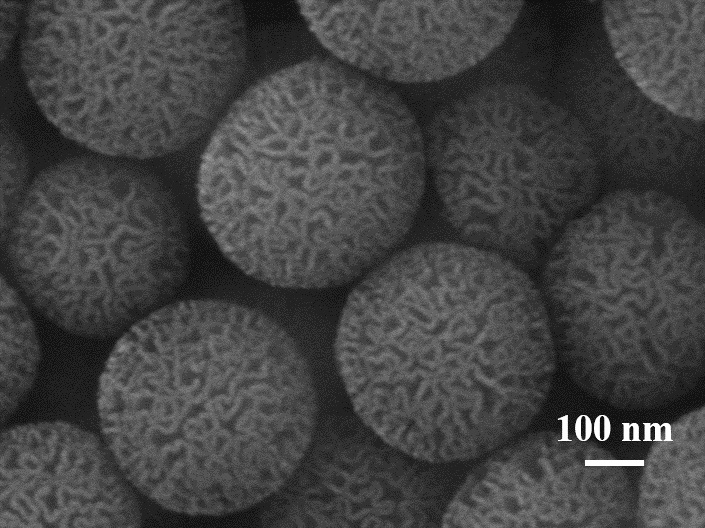

[0032] A mesoporous SiO 2 A method for preparing a surface-induced boron affinity imprinted polymer material, comprising the following steps:

[0033] a) According to the solid-to-liquid ratio (5mmol: 0.5mL: 30mL), dissolve TEOS and n-pentanol in cyclohexane, stir thoroughly and quickly add CTAB and urea to the above solution according to the molar ratio (0.2:1), add 30mL of deionized water, stirred for 30min, transferred to a hydrothermal reaction kettle, placed in a blast drying oven at 80°C, reacted for 2h, centrifuged, washed three times with acetone and distilled water, dried and placed in a tube Furnace roasting, the roasting temperature is 300°C, the roasting time is 4h, and the heating rate is 1°C / min;

[0034] b) Dissolve 0.1g of the above-prepared silicon material and 0.5mL of KH570 in 70mL of absolute ethanol, ultrasonically disperse for 0.5h, reflux at 40°C for 12h under mechanical stirring, centrifuge, wash with distilled water five times, vacuum at 30°C Dried t...

Embodiment 2

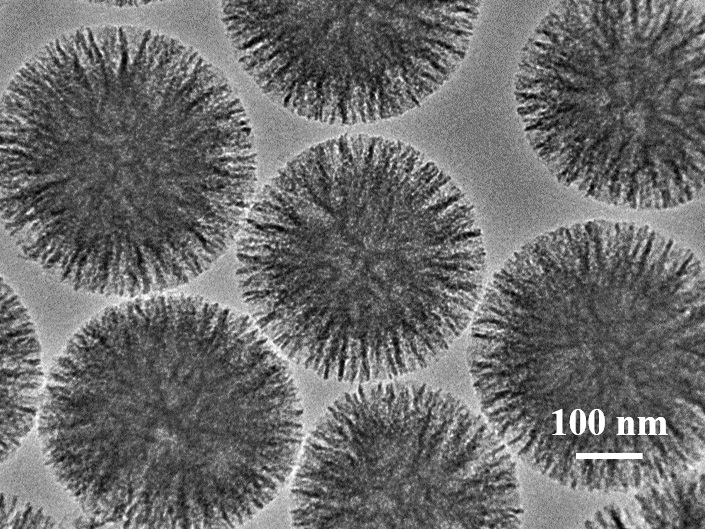

[0038] A mesoporous SiO 2 A method for preparing a surface-induced boron affinity imprinted polymer material, comprising the following steps:

[0039] a) According to the solid-to-liquid ratio (12mmol: 2mL: 30mL), dissolve TEOS and n-pentanol in cyclohexane, stir thoroughly and quickly add CTAB and urea to the above solution according to the molar ratio (0.4:1), add 30mL Deionized water, stirred for 30 minutes, transferred to a hydrothermal reaction kettle, placed in a blast drying oven at 100°C, reacted for 6 hours, centrifuged, washed with acetone and distilled water three times, dried and placed in a tube furnace Roasting, the firing temperature is 400°C, the firing time is 5h, and the heating rate is 1°C / min;

[0040] b) Dissolve 0.1g of the above-prepared silicon material and 2mL of KH570 in 70mL of absolute ethanol, under mechanical stirring, reflux at 75°C for 15h, centrifuge, wash with distilled water five times, and dry in vacuum at 30°C to obtain vinyl modification ...

Embodiment 3

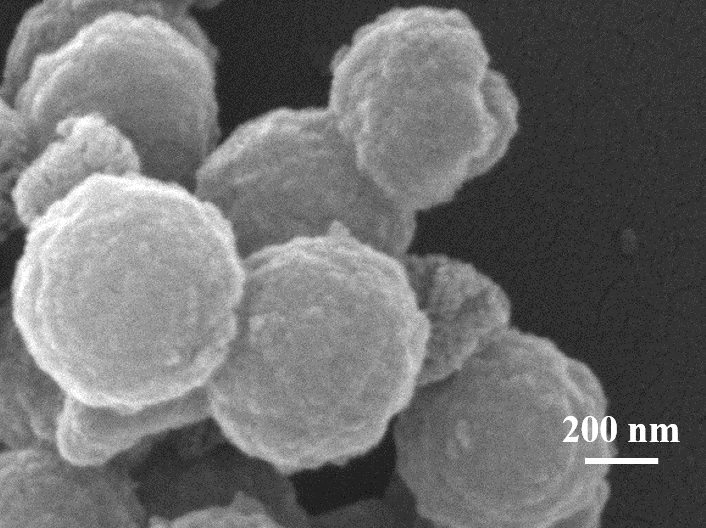

[0044] A mesoporous SiO 2 A method for preparing a surface-induced boron affinity imprinted polymer material, comprising the following steps:

[0045] a) Dissolve TEOS and n-pentanol in cyclohexane according to the solid-to-liquid ratio (15mmol: 1.5mL: 30mL), and after stirring thoroughly, quickly add CTAB and urea to the above solution according to the molar ratio (0.6:1), and add 30mL of deionized water, stirred for 30min, transferred to a hydrothermal reaction kettle, placed in a blast drying oven at 120°C, reacted for 4h, centrifuged, washed three times with acetone and distilled water, dried and placed in a tube Furnace roasting, the roasting temperature is 550°C, the roasting time is 6h, and the heating rate is 1°C / min;

[0046] b) Dissolve 0.1g of the above-prepared silicon material and 2mL of KH570 in 70mL of absolute ethanol, under mechanical stirring, reflux at 60°C for 24h, centrifuge, wash with distilled water five times, and dry in vacuum at 30°C to obtain vinyl ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com