Rectifier diode, chip special for producing rectifier diode and producing method

A technology of rectifying diodes and chips, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of low withstand voltage of chips, and achieve the effects of stable performance, reduced leakage current, and faster speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

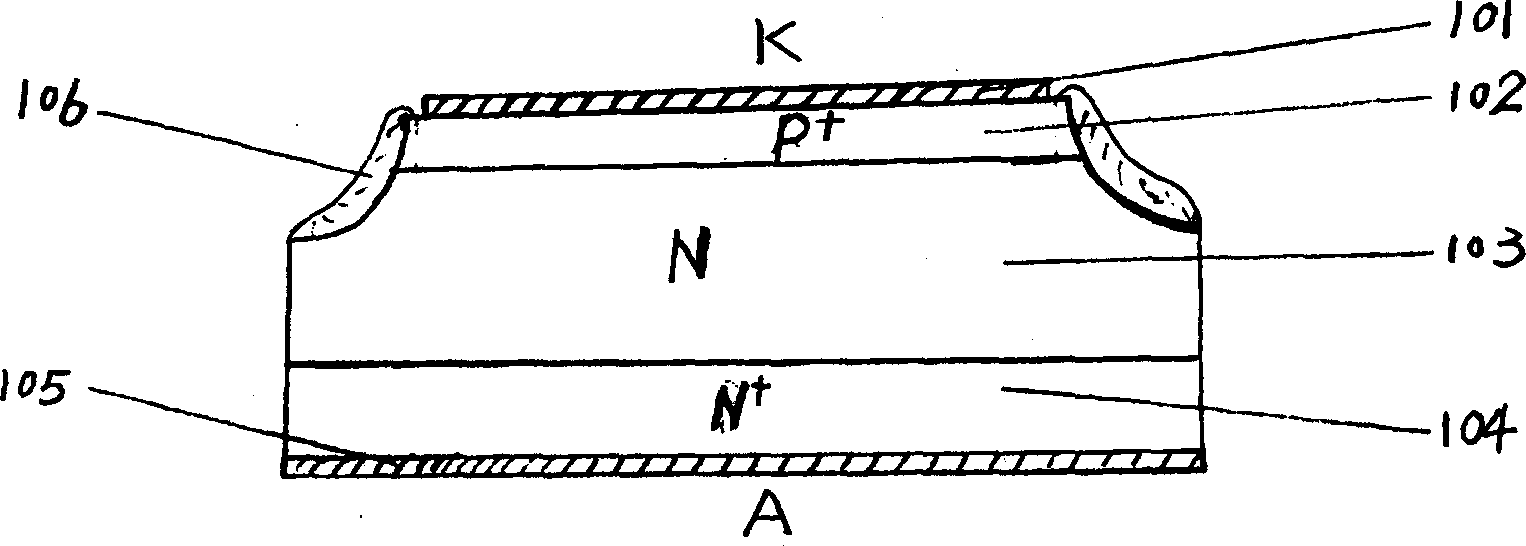

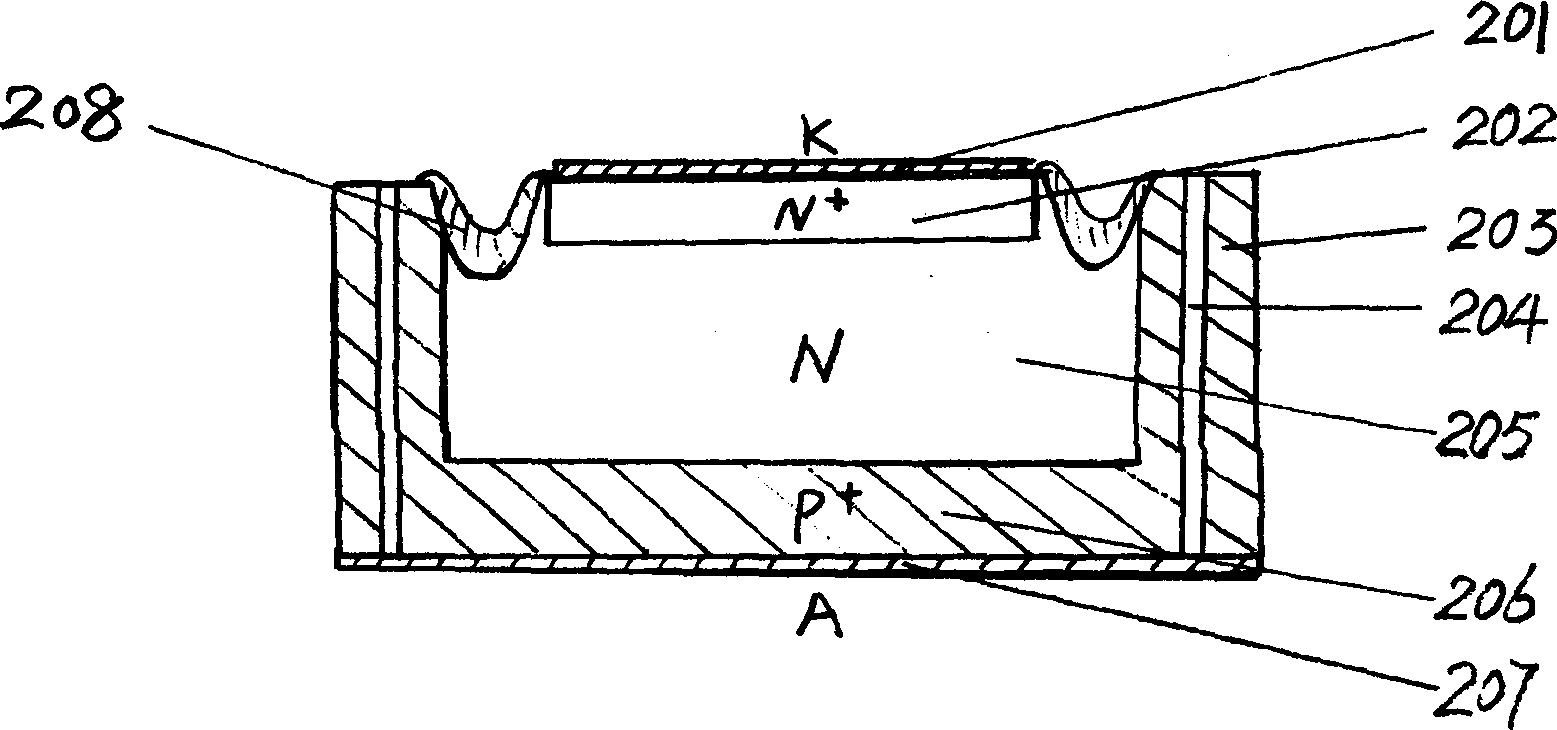

[0036] The rectifier diode is composed of three parts: the shell, the chip, and the lead wire. The core part is the chip, and the shell plays a protective role outside the chip. There are two lead wires on the anode and cathode of the chip. The chip includes a long base region N205, a phosphorous diffusion region N + 202. Concentrated boron diffusion area P + 206. Groove passivation table 208, separation wall 203, laser hole 204, cathode K201, anode A207, the middle of the chip is the long base area N205, and the upper part is the phosphorus diffusion area N + 202, the lower part is the concentrated boron diffusion area P + 206, the periphery of the chip is provided with a partition wall 203, a laser hole 204 vertically penetrated is provided on the plane of the partition wall 203, and the cathode K201 is in the phosphorus diffusion area N + 202, the anode A207 is on the concentrated boron diffusion region P+206, and the groove-type passivation mesa 208 is between the isolat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com