Curable organopolysiloxane resin composition for optical transmission components, optical transmission components, and fabrication process thereof

A technology of polysiloxane resin and light-transmitting components, which is applied in the field of light-transmitting components and curable organopolysiloxane resin compositions, and can solve problems such as increasing material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0141] This example illustrates the formation of a cured product of a methylvinylphenyl polysiloxane resin used in a light transmissive assembly. The above-mentioned methylvinylphenylpolysiloxane resins (A-1), (A-2) and (A-3) (which were used as the group component (A)), the above-mentioned methylphenylhydrogenated polysiloxanes (B-1) and (B-2) (they are used as component (B)), platinum / 1,3-divinyltetramethyl Disiloxane complex [platinum content: 2% by weight] (C) (it is used as component (C)), methyl(tris(1,1-dimethyl-2-propynyloxy))silane ( E) (which is used as a curing retarder) and toluene (which is used as component (d1)) were mixed to prepare a coating solution containing a curable organopolysiloxane resin composition for light-transmitting components.

[0142] Using an open chamber system, the coating solution was spin-coated on a silicon substrate at 2000 rpm and allowed to stand at room temperature for 10 minutes. Thereafter, a hydrosilylation-cured product of methy...

Embodiment 2

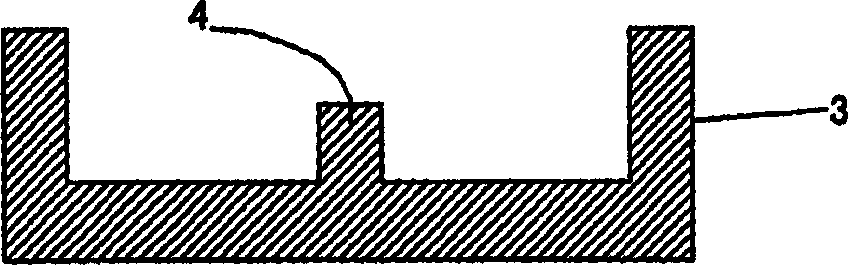

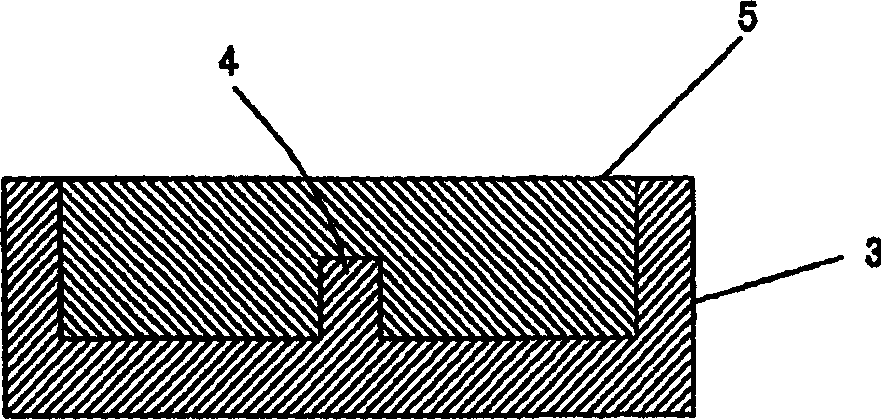

[0148] This example illustrates the formation of a groove-type optical waveguide composed of a cured product of methylvinylphenyl polysiloxane resin produced by a coating method.

[0149] Composition 5 in Table 1 was spin-coated on a silicon substrate at 2000 rpm using an open chamber system and allowed to stand at room temperature for 10 minutes. Thereafter, a film composed of a hydrosilylation cured product of methylphenylhydrogenopolysiloxane and methylvinylphenylpolysiloxane resin having a uniform thickness of 7 μm was obtained by heating at 180° C. for 90 minutes. Its refractive index is 1.519. Next, a film composed of this cured product was used as a bottom cladding, on which Composition 3 of Table 1 was spin-coated at 2000 rpm and left at room temperature for 10 minutes. Thereafter, a film composed of a hydrosilylation cured product of methylphenylhydrogenopolysiloxane and methylvinylphenylpolysiloxane resin was formed having a uniform thickness of 7 μm by heating at 1...

Embodiment 3

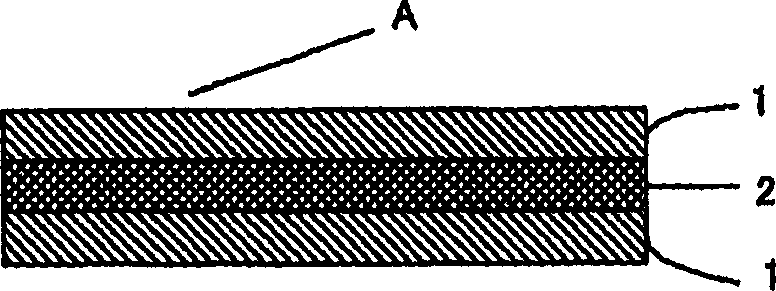

[0152] This example illustrates the formation of a strip-shaped optical waveguide composed of a cured product of methylvinylphenyl polysiloxane resin produced by a coating method. After coating composition 5 of Table 1 on a glass substrate and standing at room temperature for about 30 minutes, the composition was cured by heating at 100° C. for 1 hour and at 180° C. for 1 hour, and then at room temperature from A glass substrate was peeled off to produce a film having a thickness of 50 μm composed of a hydrosilylation cured product of methylphenylhydropolysiloxane and methylvinylphenylpolysiloxane resin. Its refractive index is 1.519. Films composed of this cured product show no polarization dependence, demonstrating that its birefringence is so small that it can be ignored.

[0153] A film composed of the cured product was used for the bottom cladding, and Composition 3 of Table 1 was coated thereon, and heat-cured in the same manner, thereby forming a core layer having a re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Uniform thickness | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Uniform thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com