Nano-screen and its manufacturing method

A technology of nano-sieve mesh and manufacturing method, which is applied in chemical instruments and methods, semi-permeable membrane separation, membrane technology and other directions, can solve the problems of low screening efficiency and low effective utilization area of nano-sieve mesh, and achieves faster screening rate, increased Effective use of area and improved screening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

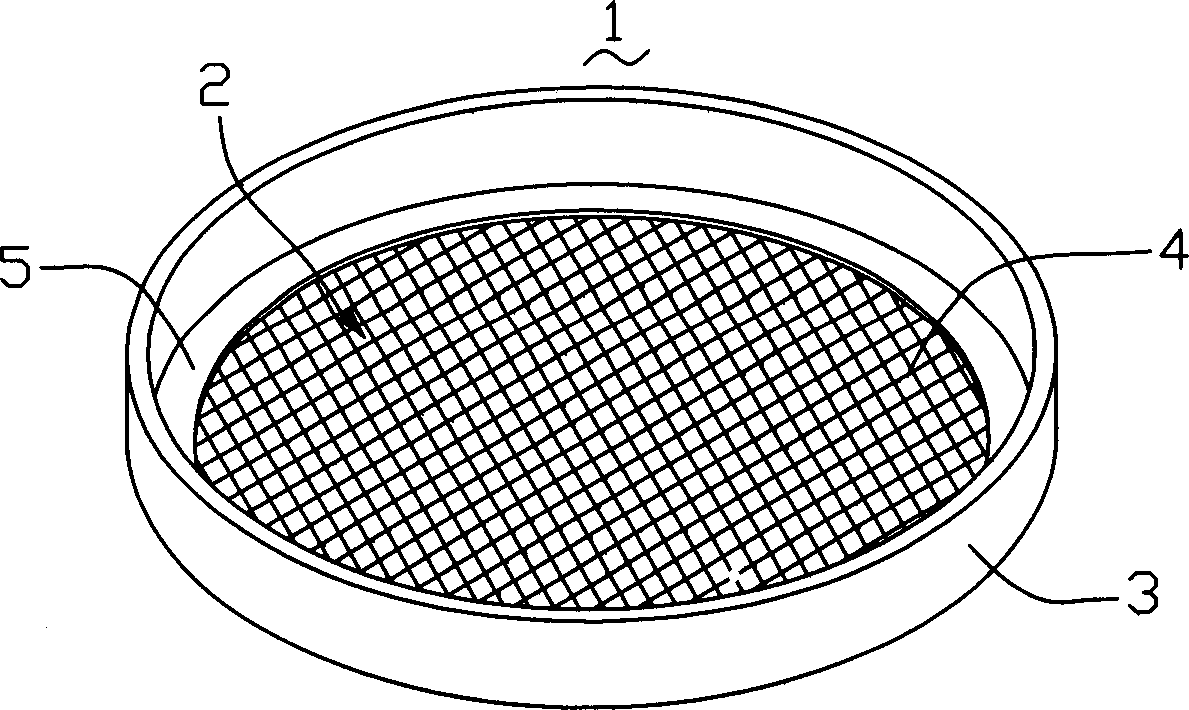

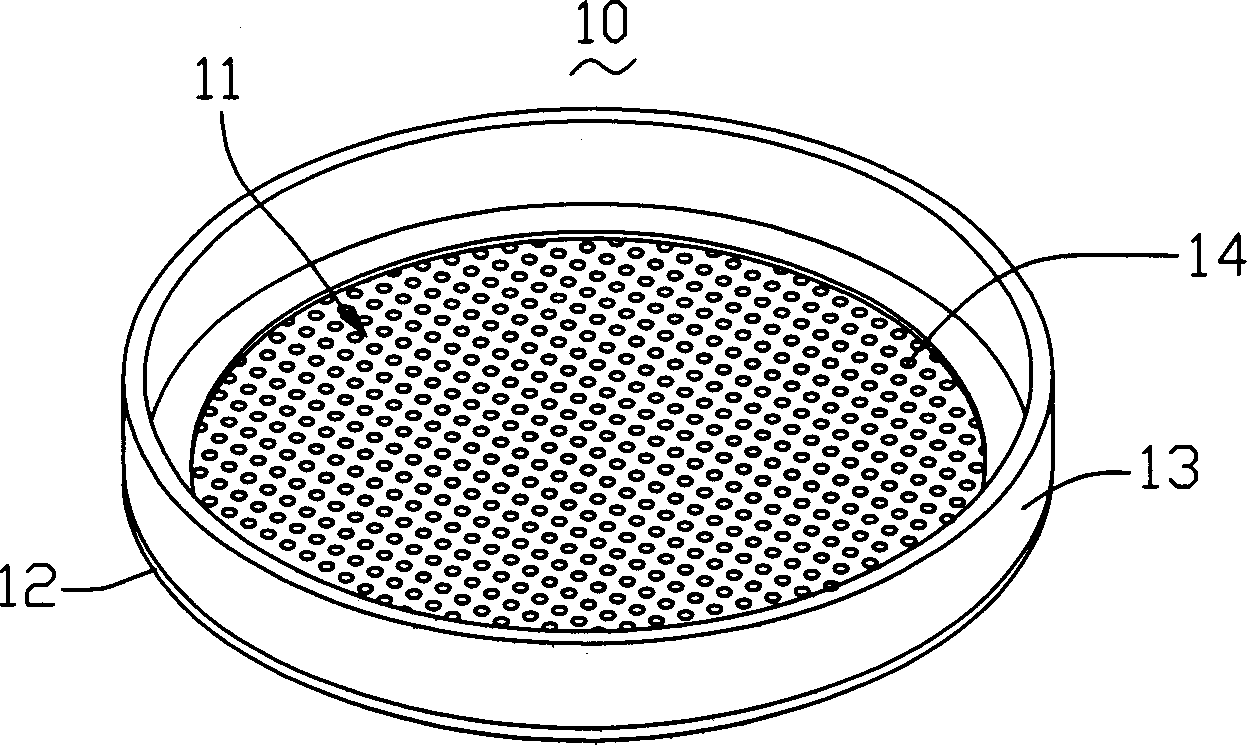

[0029] see figure 2 , the nanosieve 10 provided by the present invention includes a film 11 , a chassis 12 for holding the film, and a side wall 13 formed on the periphery of the chassis 12 . Wherein, the chassis 12 is a base with a hollow center, so that the film 11 can be held at the center of the chassis 12 . The side wall 13 has a certain height and can hold a certain amount of powder to be screened (not shown). The membrane 11 is a porous aluminum oxide membrane, and nanometer filter holes 14 regularly arranged in a certain direction are formed in its thickness direction.

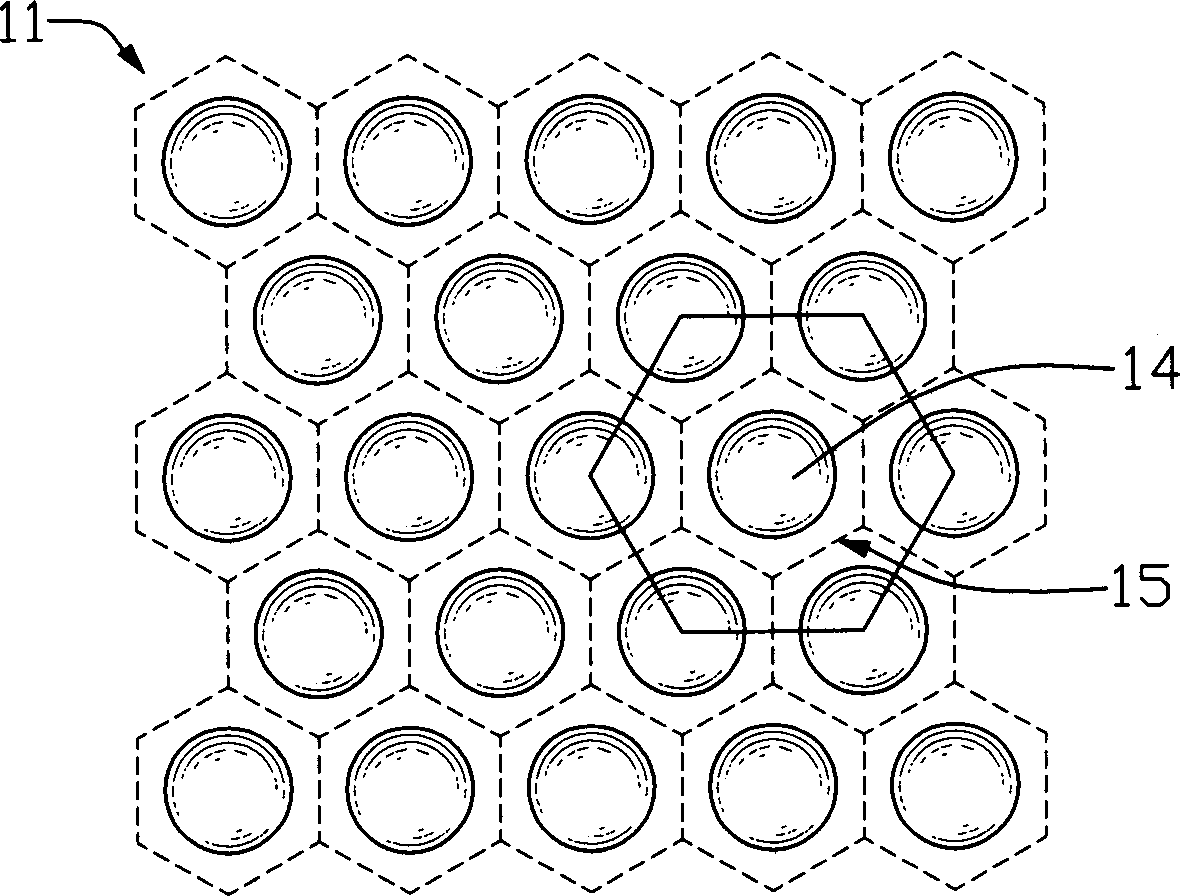

[0030] see image 3 , is an enlarged schematic view of the surface structure of the film 11 in the nanosieve 10 . Thin film 11 is made up of many unit cells 15 with hexahedron shape (as shown by dotted line in the figure), and each unit cell 15 center contains a cylindrical hole shape nano filter hole 14, and each unit cell 15 surrounds by hexagon There are six identical unit cells arranged therei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com