Heavy soda ash fluidized calcoining coling system and process thereof

A cooling system and calcination technology, which is applied in the direction of alkali metal carbonate to change the crystal water content, etc., can solve the problems of large amount of drying and cooling air, affecting the service life of the exhaust fan, and short operation period of the device, so as to reduce the amount of equipment maintenance , Guarantee the quality of calcination, the effect of small investment in plant and civil engineering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

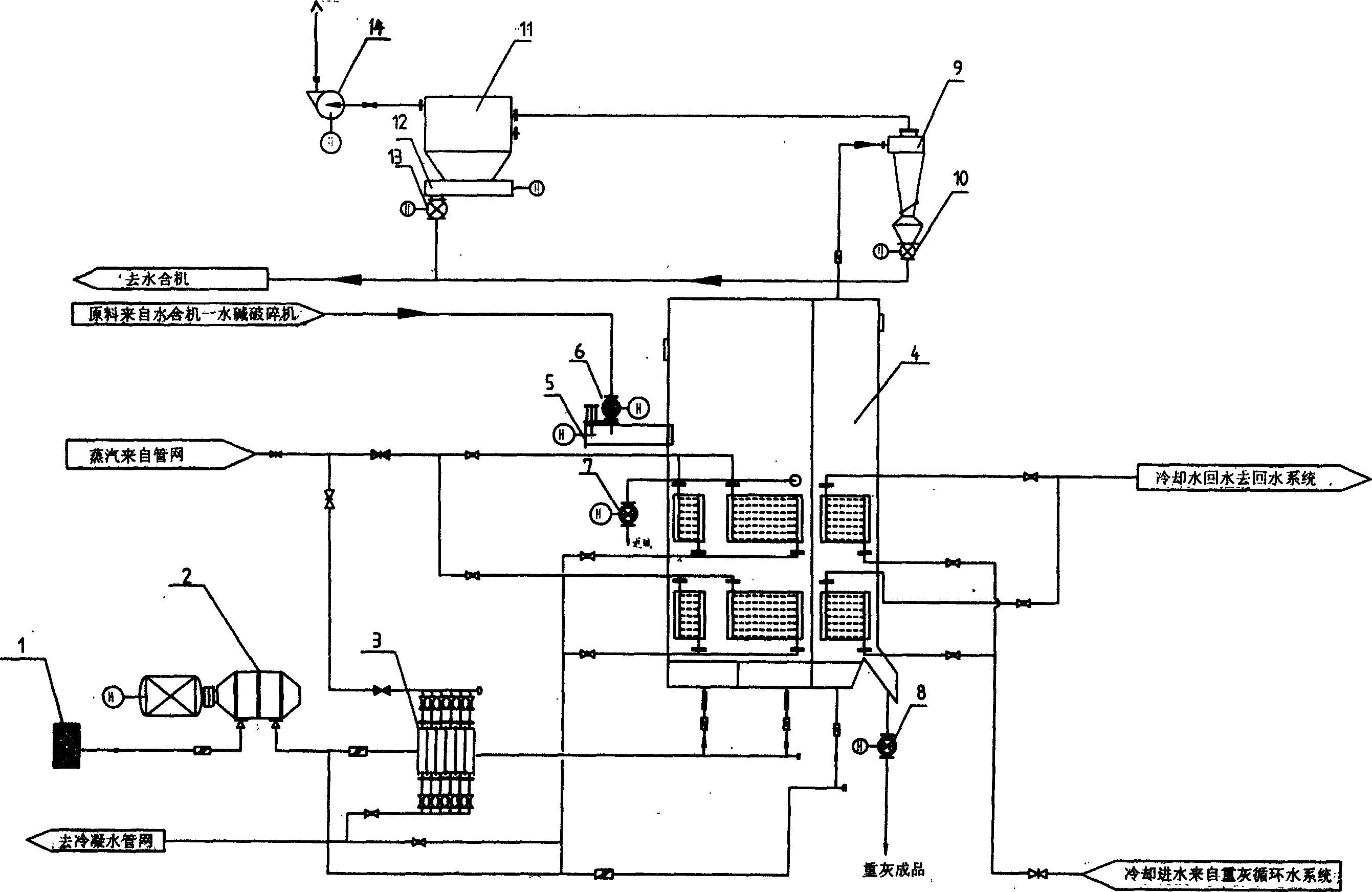

[0032]The composition of the system of the present invention is shown in FIG. 1 , the feeding star feeder 6 is connected with the mixing conveyor 5 . The alkali-returning feeder 7 is also connected with the alkali-returning feed port of the mixing conveyor 5, and the mixing conveyor 5 is connected with the side of the heavy alkali fluidized bed 4 calciner. The calciner has built-in heat exchange tubes, and the heat exchange tubes are arranged as In the form of serpentine tubes, the front calcining part is connected with the steam pipe and the condensed water recovery pipe, and the rear cooling part is connected with the cooling water pipe and the cooling return water pipe. Simultaneously, the discharge port of the calciner is connected with the finished product area through the discharge rotary discharge valve 8 . The top of the heavy alkali fluidized bed 4 is also connected to the cyclone dust collector 9 , the upper part of the cyclone dust collector 9 is connected to the ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com