Treatment and reuse method of high temperature dyeing waste water

A dyeing wastewater, high temperature technology, applied in water/sewage multi-stage treatment, adsorption water/sewage treatment, illumination water/sewage treatment, etc. The effect of saving production costs and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

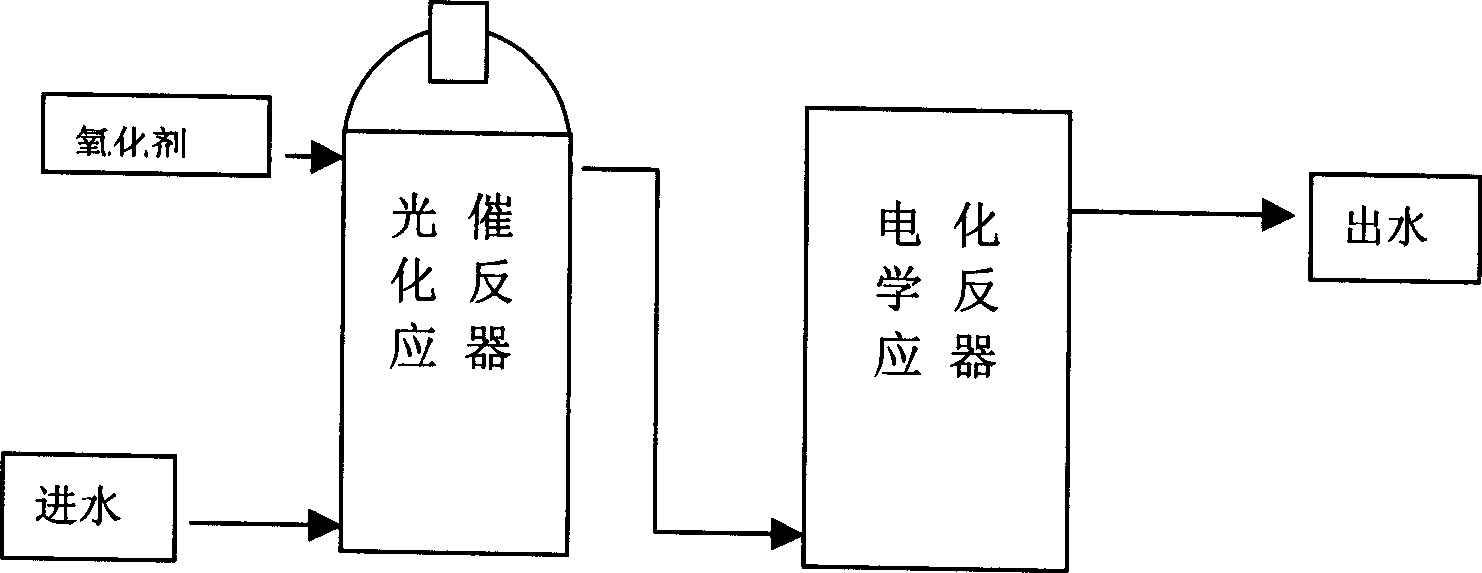

[0020] The invention is a combination technology of microwave-ultraviolet photocatalytic oxidation-electrochemical oxidation to treat and reuse high-temperature dyeing wastewater.

[0021] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

[0022] 1. Treatment and reuse method of high temperature dyeing wastewater

[0023] Specific steps are as follows:

[0024] After filtering the high-temperature dyeing wastewater with a sand filter, the high-temperature dyeing wastewater is filtered with a sand filter, and then enters the photocatalytic reactor;

[0025] Adding an oxidizing agent to carry out microwave degradation and photocatalytic oxidation with extreme ultraviolet light;

[0026] In the process of photochemical reaction, air is blown in, and ultraviolet light is generated under the excitation of microwaves. The air generates ozone under the strong catalysis of ultraviolet light, and ozone cooperates wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com