Method for mfg, ligth conducting plate

A manufacturing method and technology for a light guide plate, which are applied in the field of light guide plates, can solve the problems of inability to perform optical adjustment and control the distribution of scattered particles, and achieve the effects of improving light utilization and reducing light loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The steps of the manufacturing method of the light guide plate of the present invention are as follows:

[0028] Perform optical design and perform optical simulations.

[0029] A laser engraving machine is provided, and optical design data is input into the laser engraving machine and converted into processing information and programs.

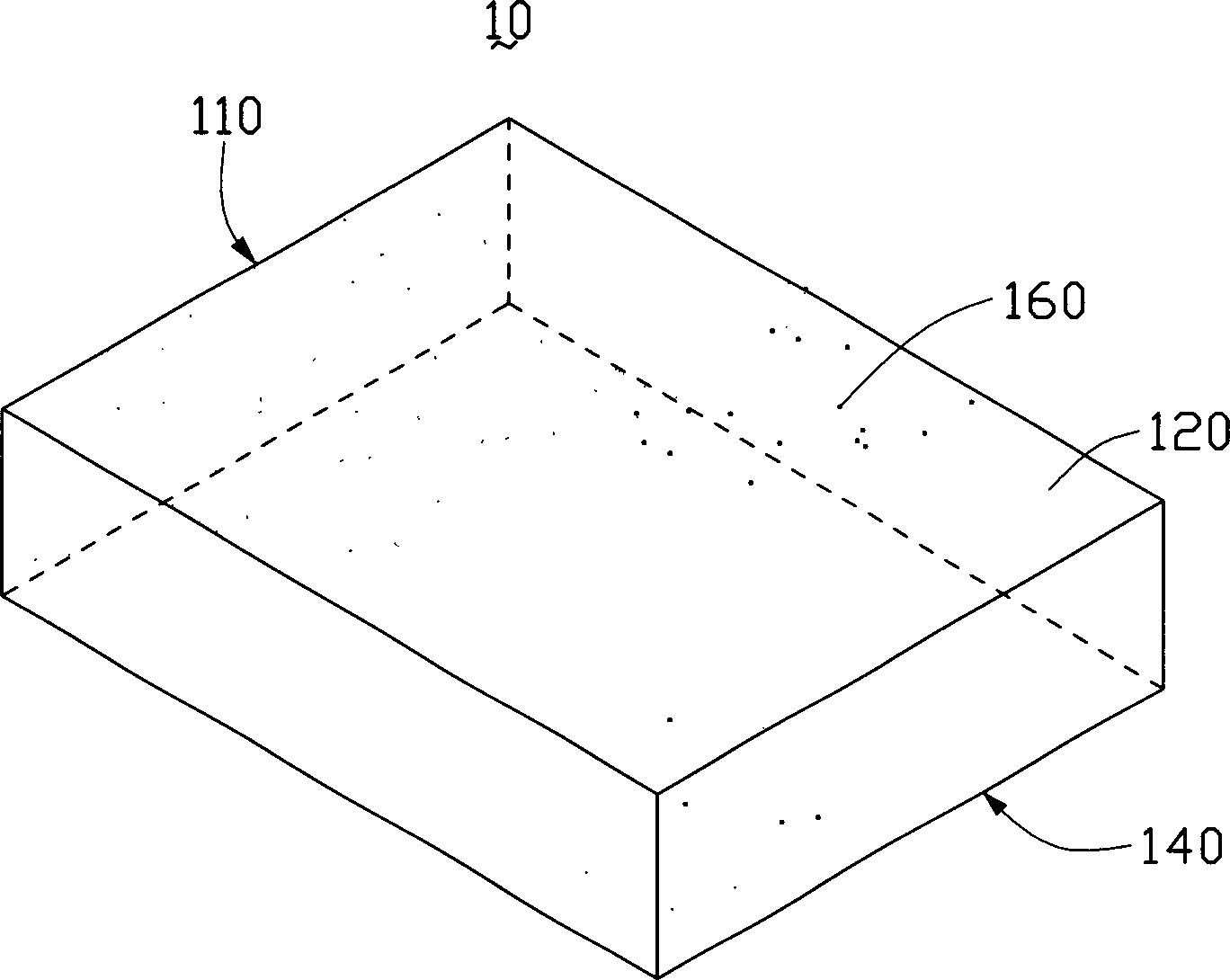

[0030] A substrate is provided, and the material of the substrate is transparent organic resin, or glass.

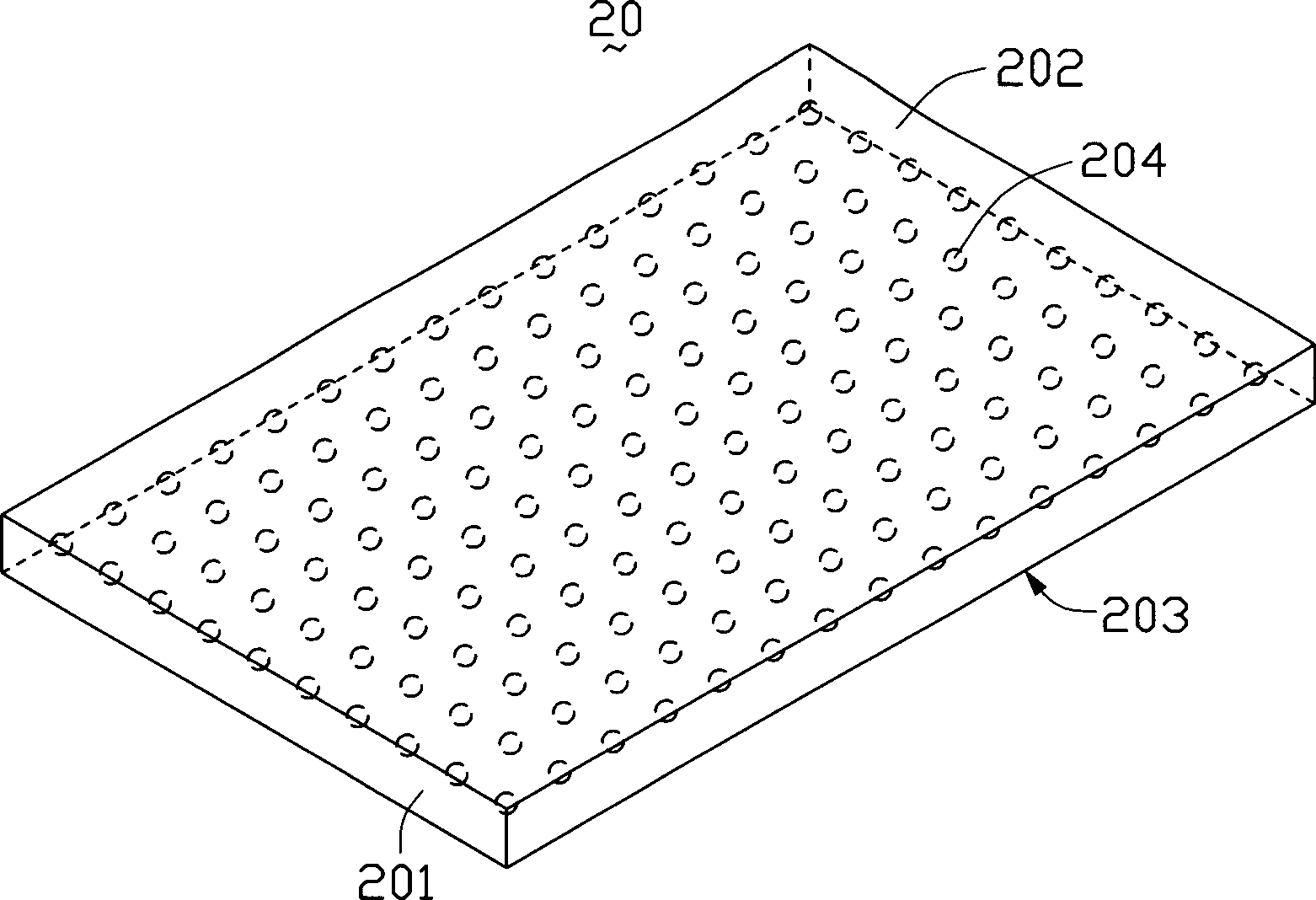

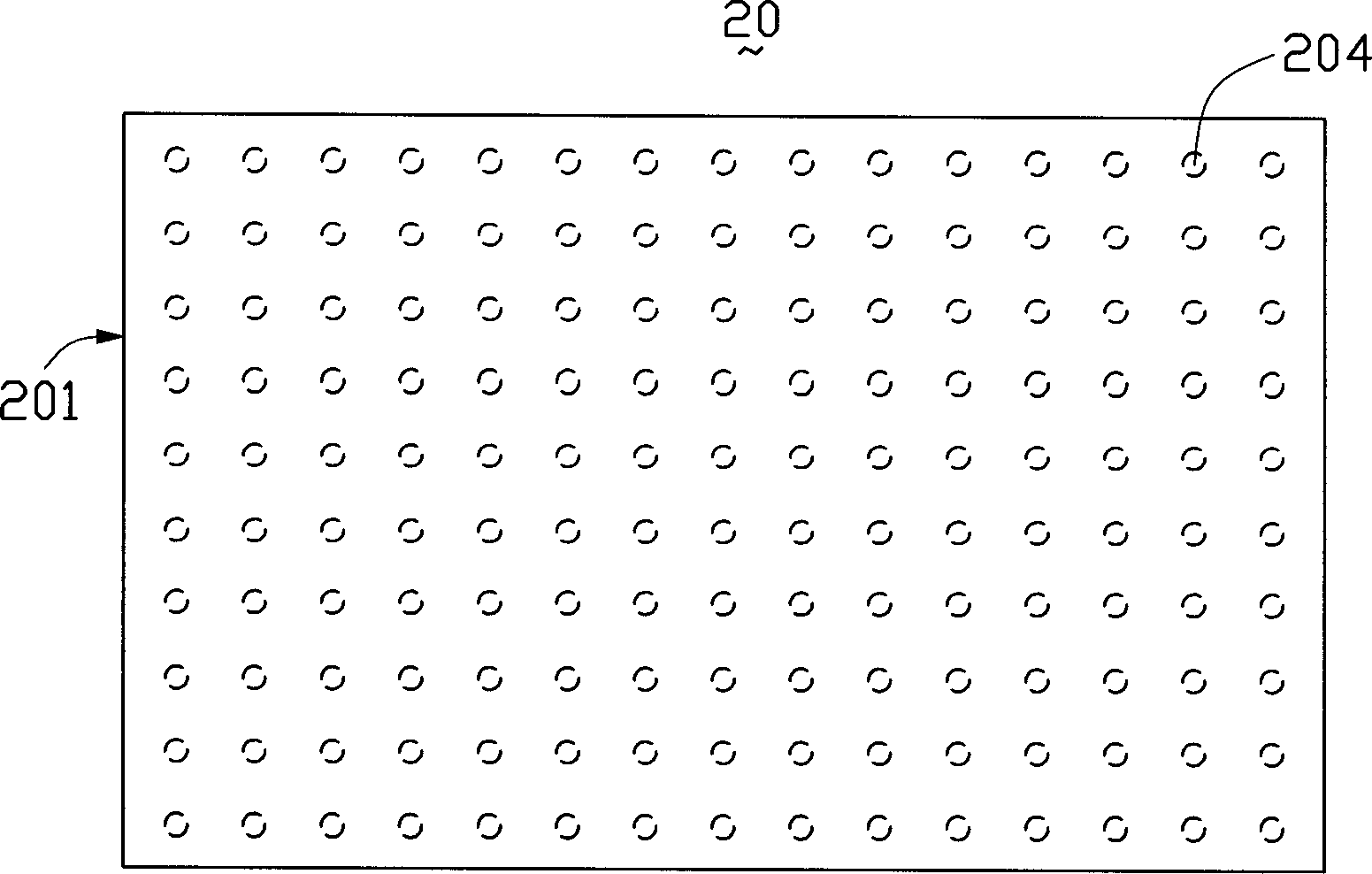

[0031] Drive the laser engraving machine to form a plurality of light diffusion points in the substrate according to the processing information and program to form a light guide plate. The plurality of light diffusion points can be processed into hemispherical, spherical, conical or inverted pyramid structures capable of scattering light.

[0032] In addition to the laser internal engraving technique, the manufacturing method of the light guide plate of the present invention can also adopt the ultrasonic internal engraving tech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com