Apparatus and method for preparing nitrobenzene by nitration of tubular benzene

A production device and technology for nitrobenzene, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of overheating, uneven mixing of materials, uneven residence time of materials, etc., and reduce environmental pollution and equipment. The effect of low investment and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

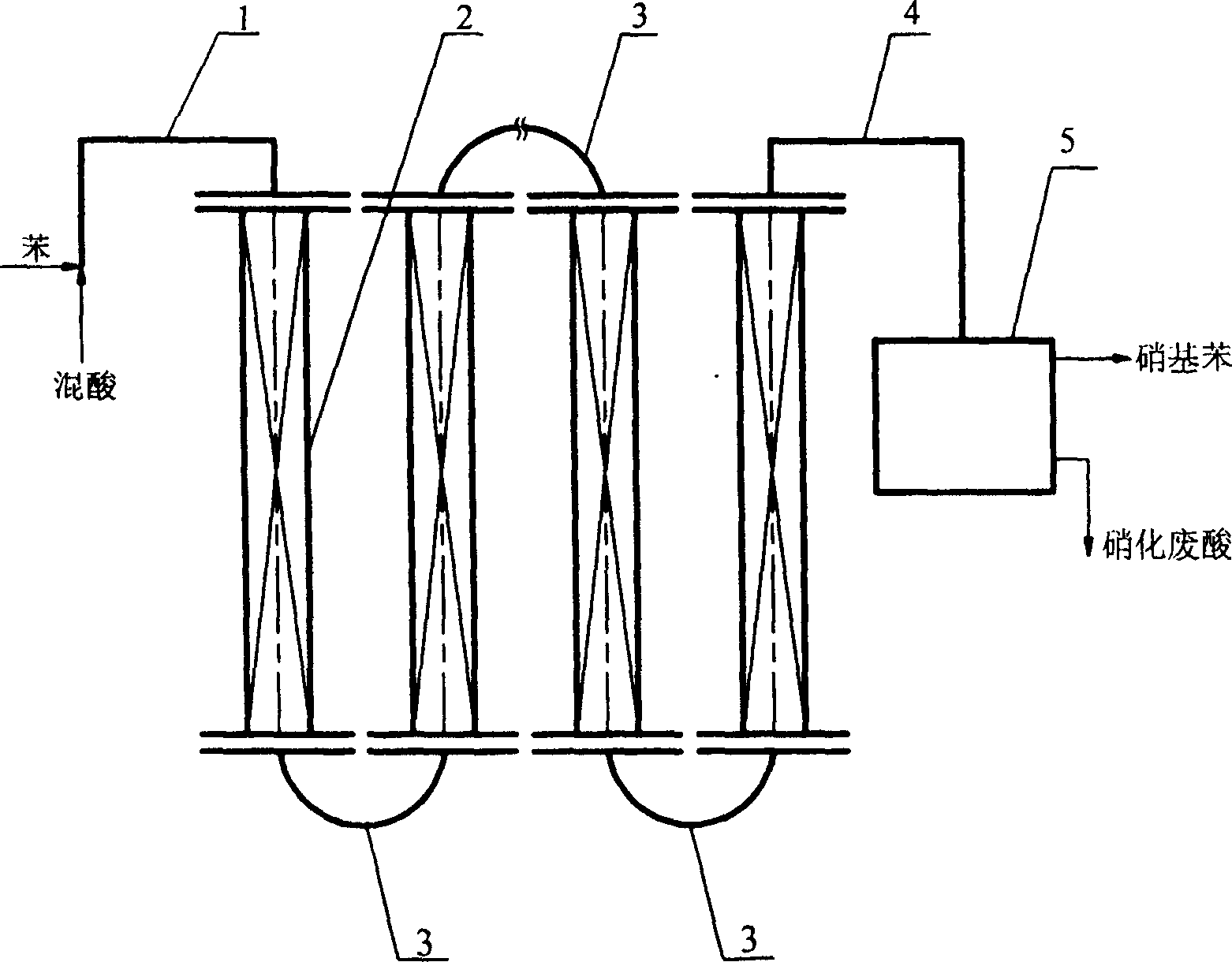

[0030] The tubular benzene nitration production device for producing nitrobenzene includes a mixed acid and benzene inlet pipe 1, a 14-stage nitration reaction pipe 2, a 13-stage connecting pipe 3, a nitration mixture outlet pipe 4, and a nitration mixture separator 5. The above-mentioned nitrification reaction tube 2 is provided with chemical fillers or mixing elements. The diameter of each nitrification mixing tube is 150mm and the length is 6000mm.

[0031] The specific installation method: the mixed acid and benzene inlet pipe 1 is connected with the inlet of the nitrification reaction pipe 2, the nitrification reaction pipe 2 is connected by the connecting pipe 3, the outlet of the nitrification reaction pipe 2 is connected with the nitrification mixture outlet pipe 4, and the nitrification mixture outlet pipe 2 is connected. The other end links with the nitration mixture separator 5. The nitrification reaction tube 2 is arranged vertically.

Embodiment 2

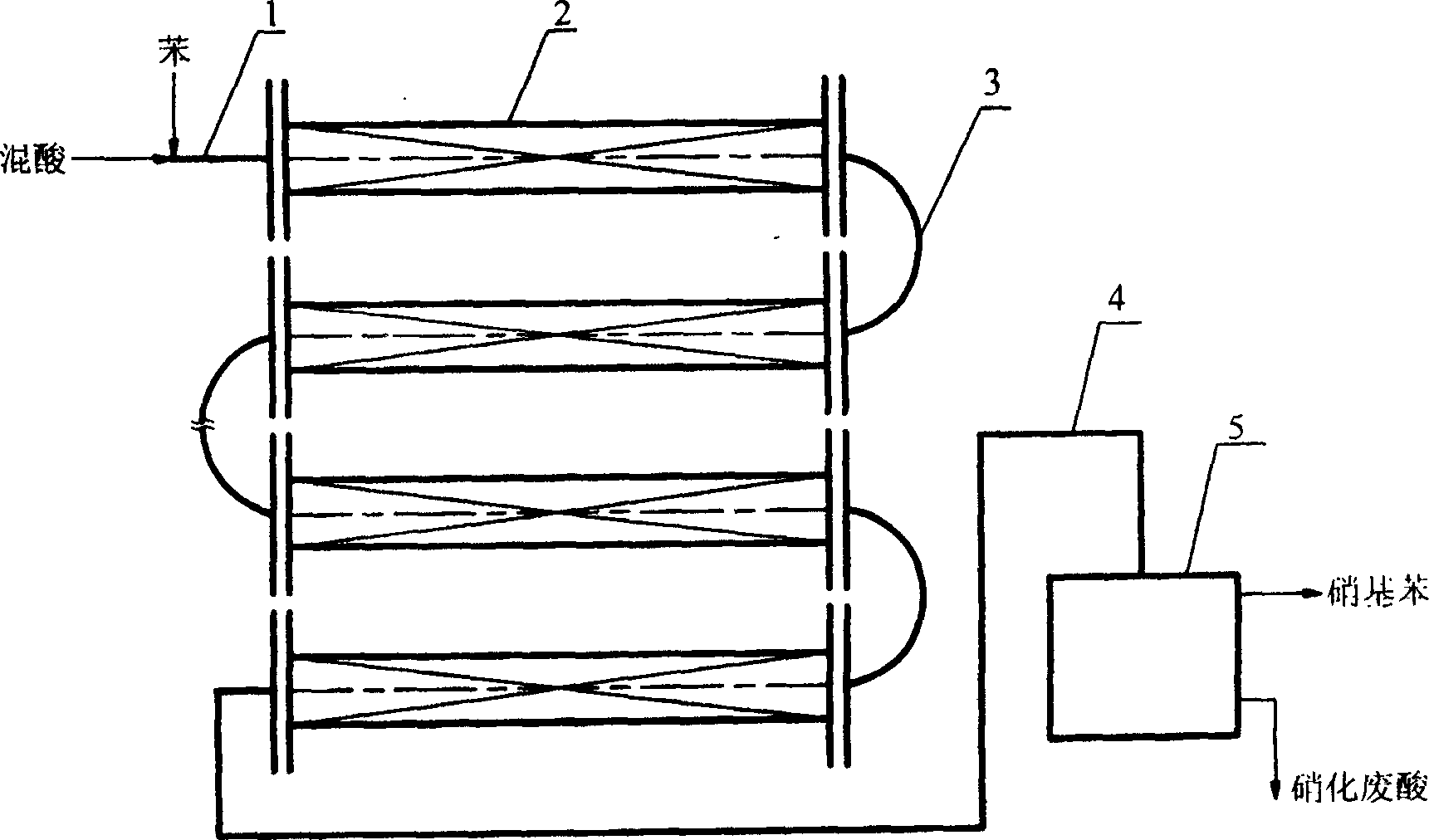

[0033] The tubular benzene nitration production device for producing nitrobenzene includes a mixed acid and benzene inlet pipe 1, a 24-stage nitration reaction pipe 2, a 23-stage connecting pipe 3, a nitration mixture outlet pipeline 4, and a nitration mixture separator 5. The diameter of each nitrification reaction tube is 300mm, and the length is 4000mm.

[0034] Specific installation method:

[0035] The specific installation method is the same as that of the first embodiment.

Embodiment 3

[0037] Embodiment 3 is basically the same as Embodiment 1, except that the nitrification reaction tube is arranged horizontally.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com