Straight nuclear reactor fuel assembly refueling, loading and unloading technique

A nuclear reactor fuel and fuel assembly technology, applied in reactor fuel elements, reactors, nuclear engineering, etc., can solve the problems of inoperable spent fuel assemblies, increasing the radioactive dose level of the reactor building, and unfavorable control of the temperature and humidity of the reactor building, etc. To achieve the effect of improving economy, reducing cost and fast time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

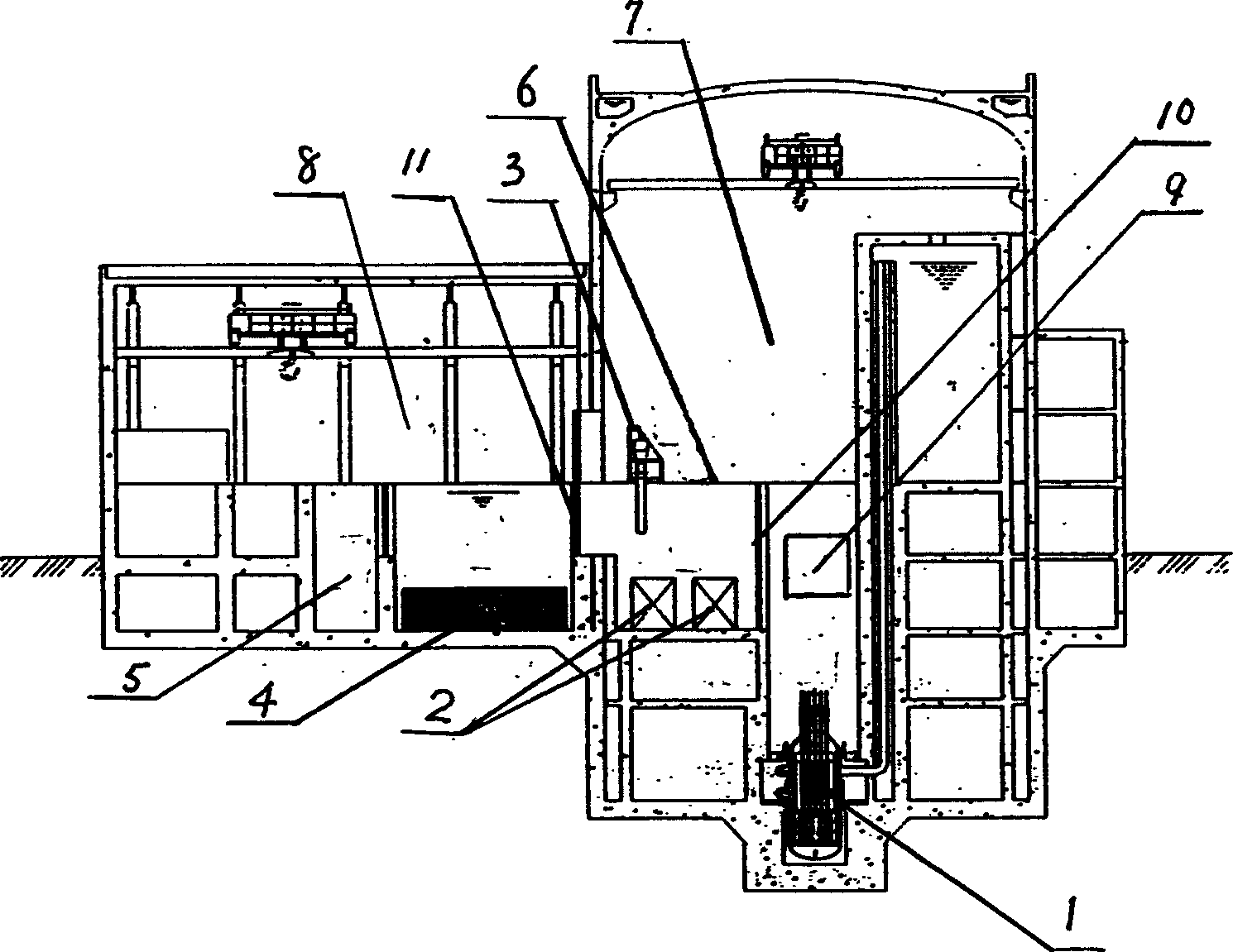

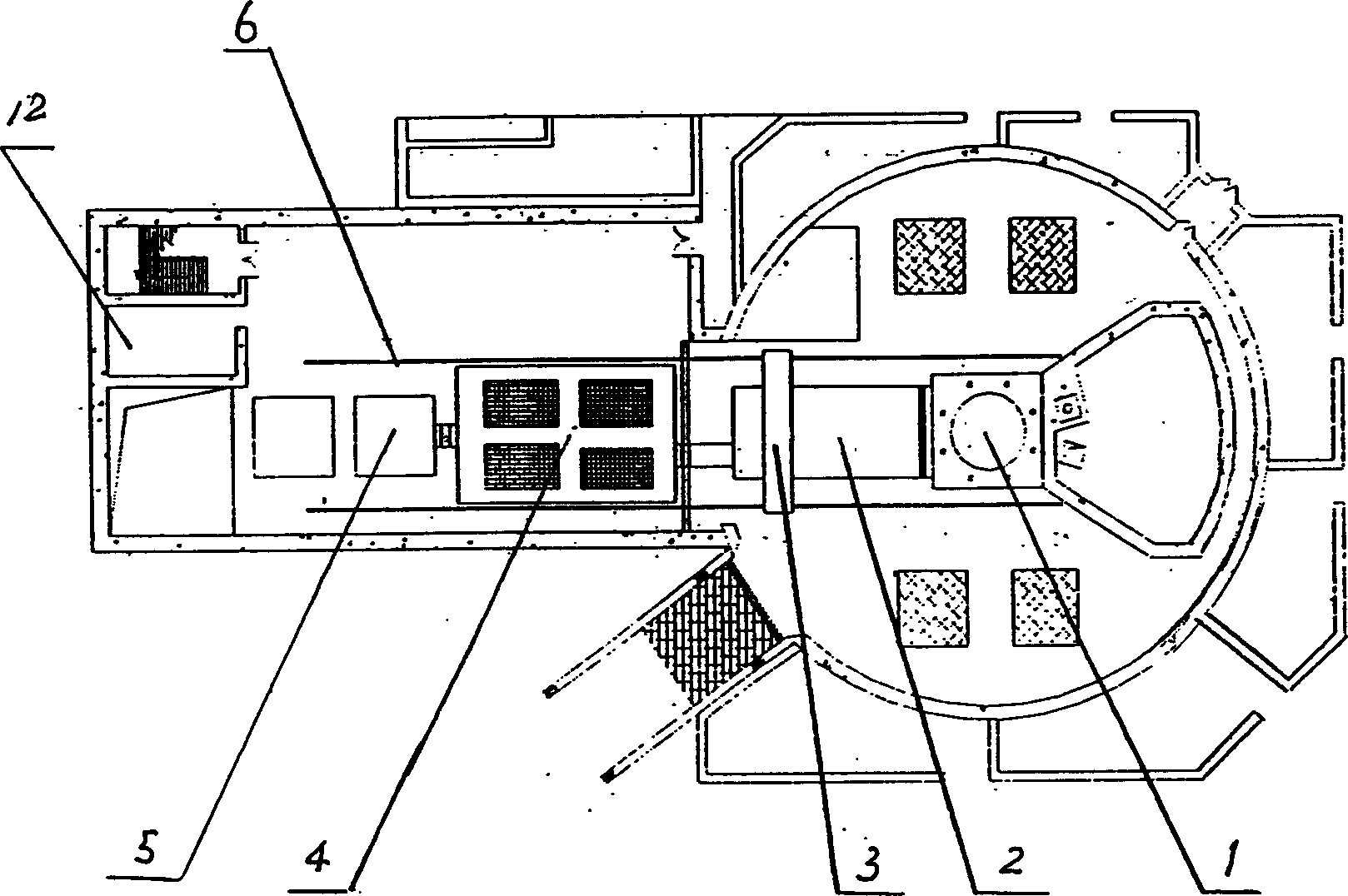

[0009] Such as figure 1 and figure 2 As shown, a fuel assembly refueling and loading and unloading process for a straight-running nuclear reactor includes the following operations:

[0010] (1) The fuel transport container containing the new fuel assembly is hoisted to the fuel tank pool 5 by a 130-ton fuel plant crane; the 5-ton fuel plant auxiliary crane lifts the new fuel assembly from the tank to the new fuel inspection and storage room 12 Carry out inspection and storage; before refueling, transfer the new fuel assembly to the designated grid position of the spent fuel storage pool 4 for storage.

[0011] (2) When the reactor is shut down, the top cover of the reactor pressure vessel 1, the control rod drive mechanism, and some reactor internals are removed before refueling operation, and stored in the reactor internals storage pool 2. Open the refueling gate 11 between the reactor building 7 and the fuel building 8 and the connection gate 10 between the reactor pool 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com