Optical switch

An optical switch and side light technology, applied in the field of optical switches, can solve the problems of poor adjustment, reduced optical switch productivity, low efficiency, etc., and achieve the effects of reducing insertion loss, reducing driving parts, and seeking miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

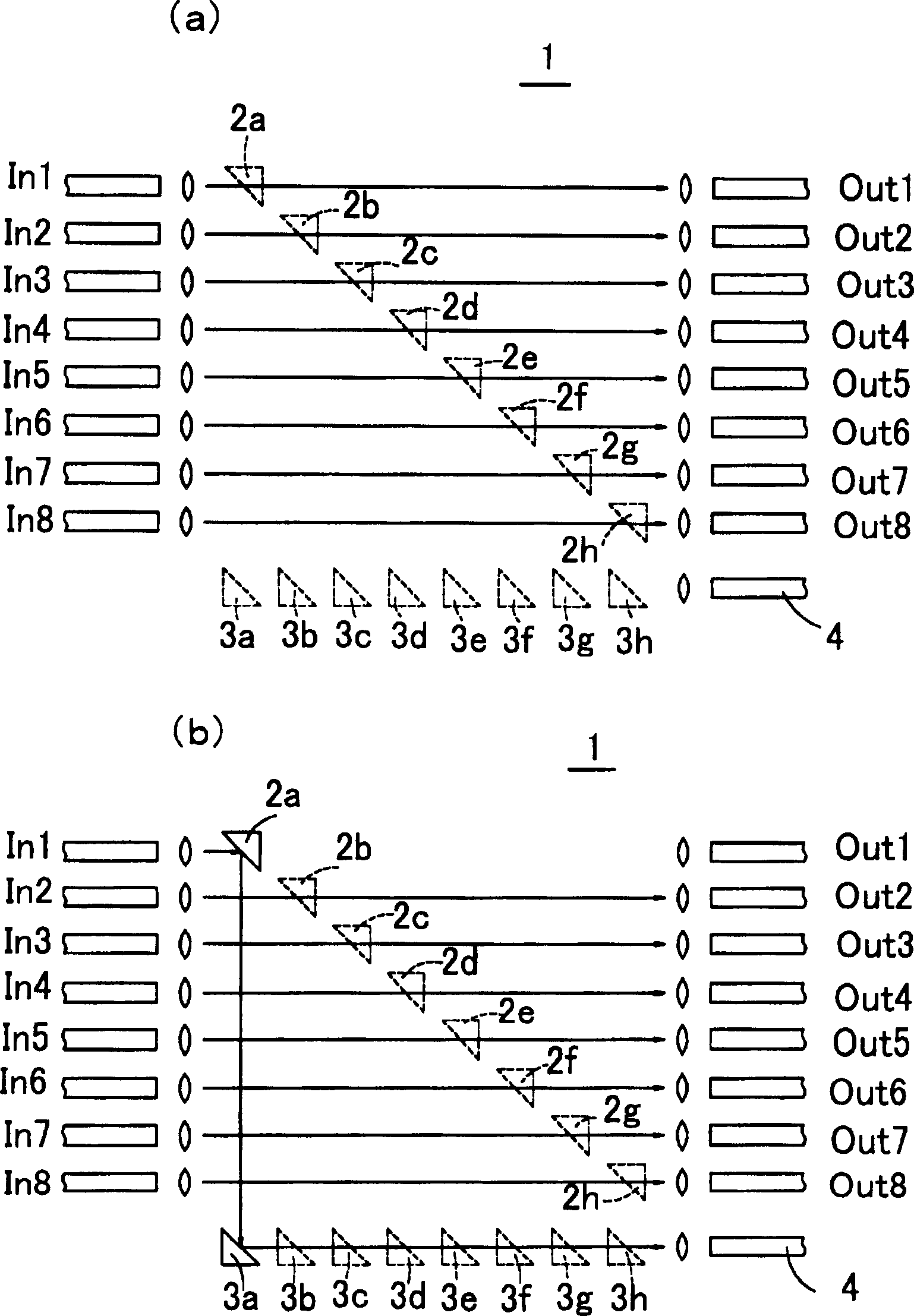

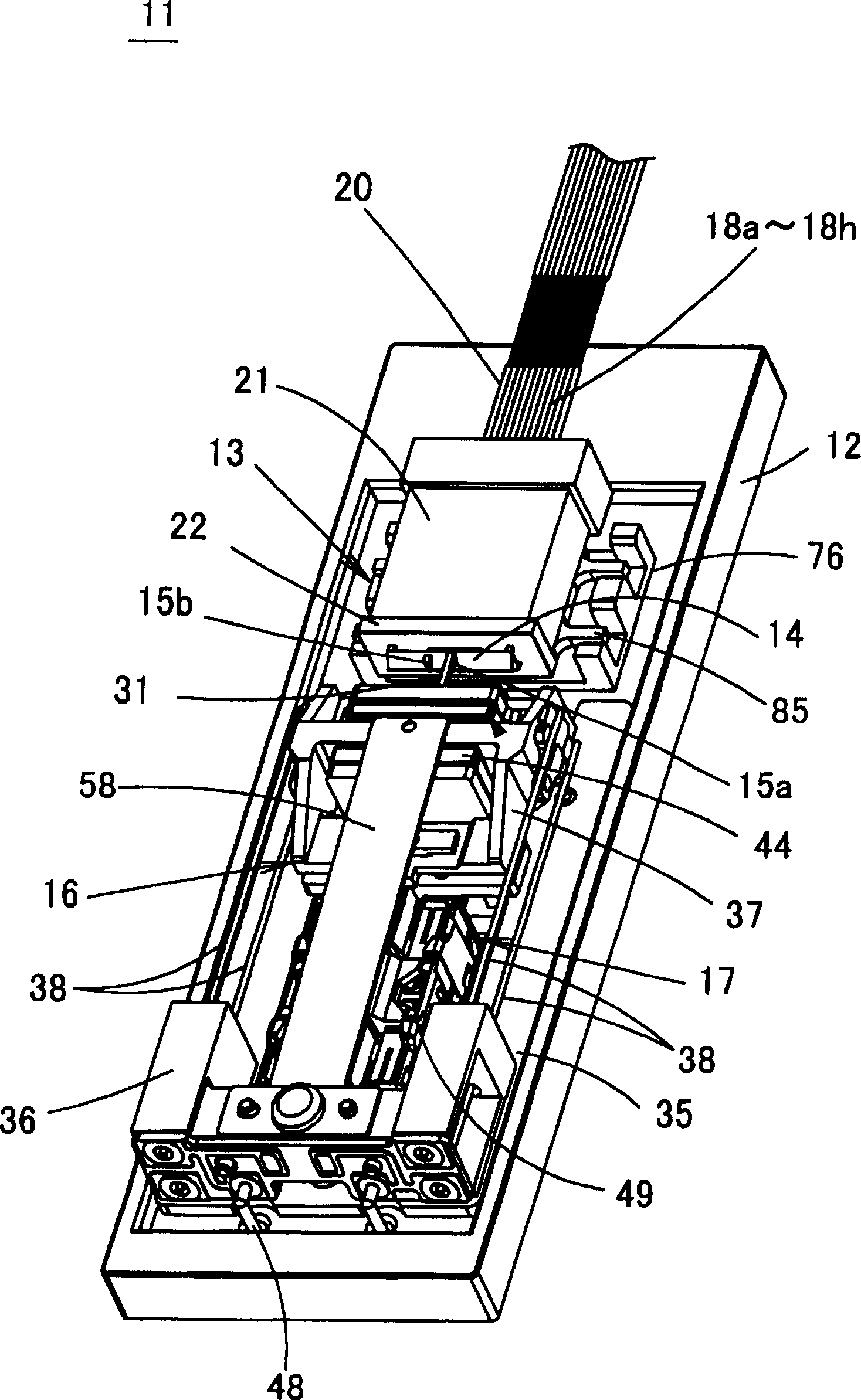

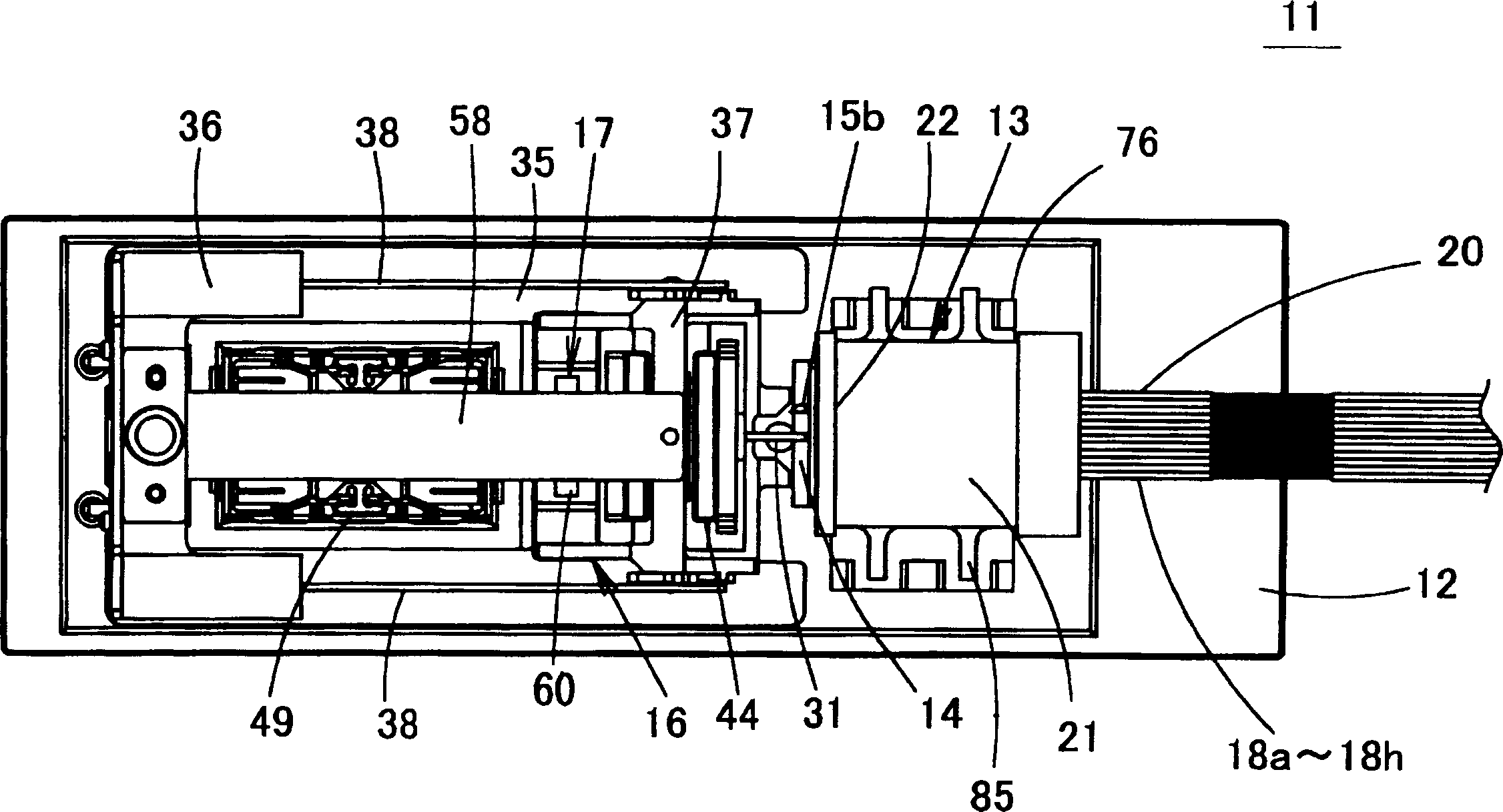

[0045] figure 2 is a perspective view of the optical switch (standby optical switch) of the first embodiment of the present invention, image 3 is its floor plan, Figure 4 is its side view. In this optical switch 11 , an input / output unit 13 , a prism driving unit 16 and a positioning unit 17 are mounted on a base 12 made of ceramics, metal, plastic, or the like. A fixed prism 14 is attached to the input / output section 13, a prism 15b for a preliminary fiber is attached to the fixed prism 14, and a prism driving section 16 holds the driving prism 15a.

[0046] The input / output unit 13 is provided with: a plurality of input-side optical fibers (fiber array) 18a to 18h serving as an input-side optical transmission path, a plurality of output-side optical fibers (fiber array) 19a to 19h to be an output-side optical transmission path, and a single backup optical fiber. (spare optical fiber) 20, and they are bundled into one by connectors 21 such as MT connectors. Figure 5 (...

no. 2 example

[0082] Figure 22 It is a perspective view showing the structure of an optical switch in other embodiments of the present invention, Figure 23 is its floor plan, Figure 24 is its side view. This optical switch 91 has substantially the same structure as that of the optical switch 11 of the first embodiment except for the structure of the positioning portion 17 . That is, in the positioning portion 17 of the optical switch 91 , the base end portion of the leaf spring 92 bent into a step shape is joined to the upper surface of the front end portion of the movable iron piece 63 of the electromagnetic driver 49 . A pressing protrusion 93 for pressing the prism holder 37 is provided on the lower surface of the front end portion of the leaf spring 92 . It directly presses the prism seat 37 through the leaf spring 92 installed on the movable iron piece 63 .

[0083] Next, the operation of this optical switch 91 will be described. Under the situation that the electromagnetic dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com