Bed die floating regulating mechanism of powder forming machine

A floating adjustment and forming machine technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of unsynchronized action of the linkage mechanism, complex structure of the linkage mechanism, poor structural stability, etc., and achieves easy assembly, simple structure, and adjustable speed. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

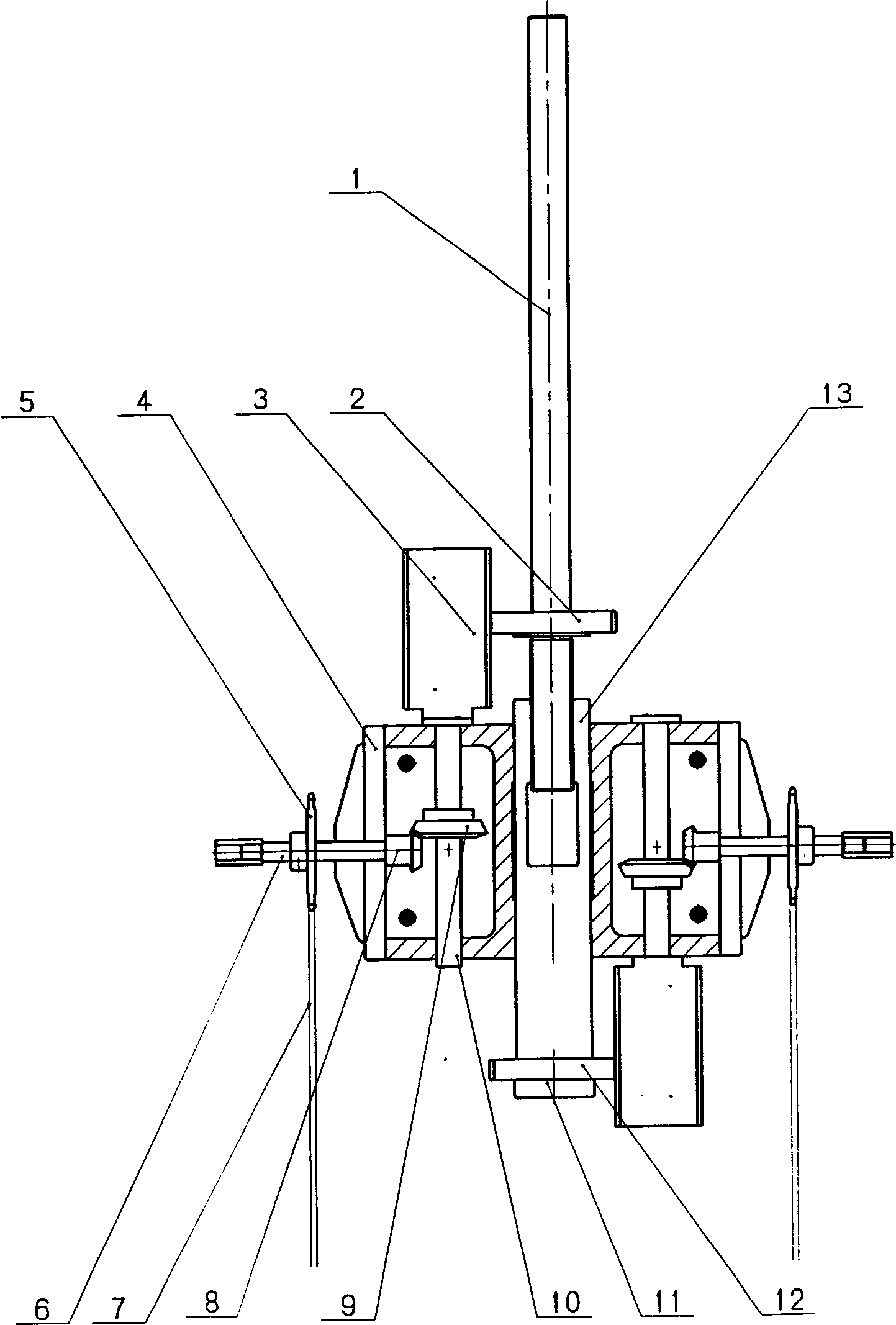

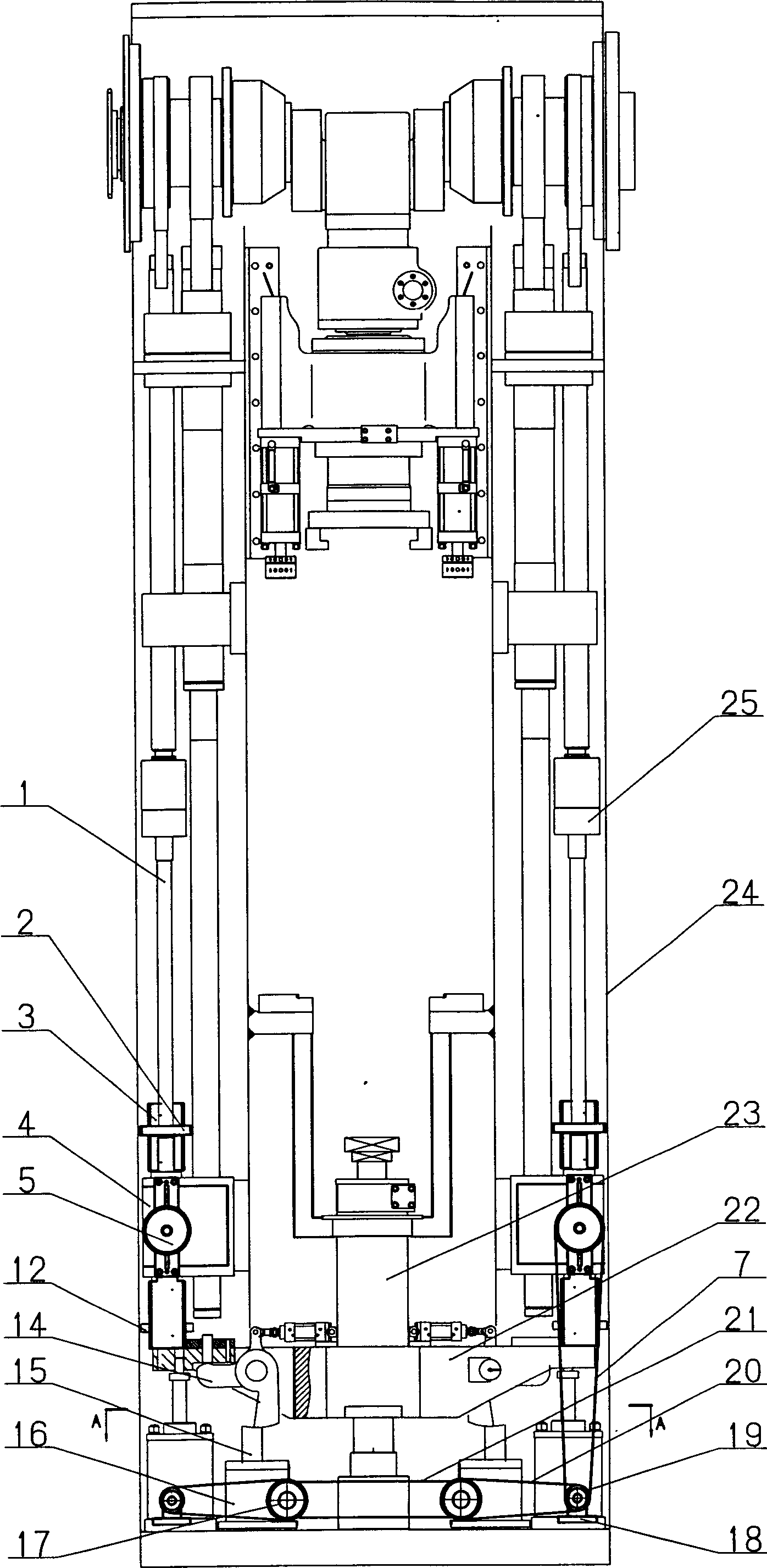

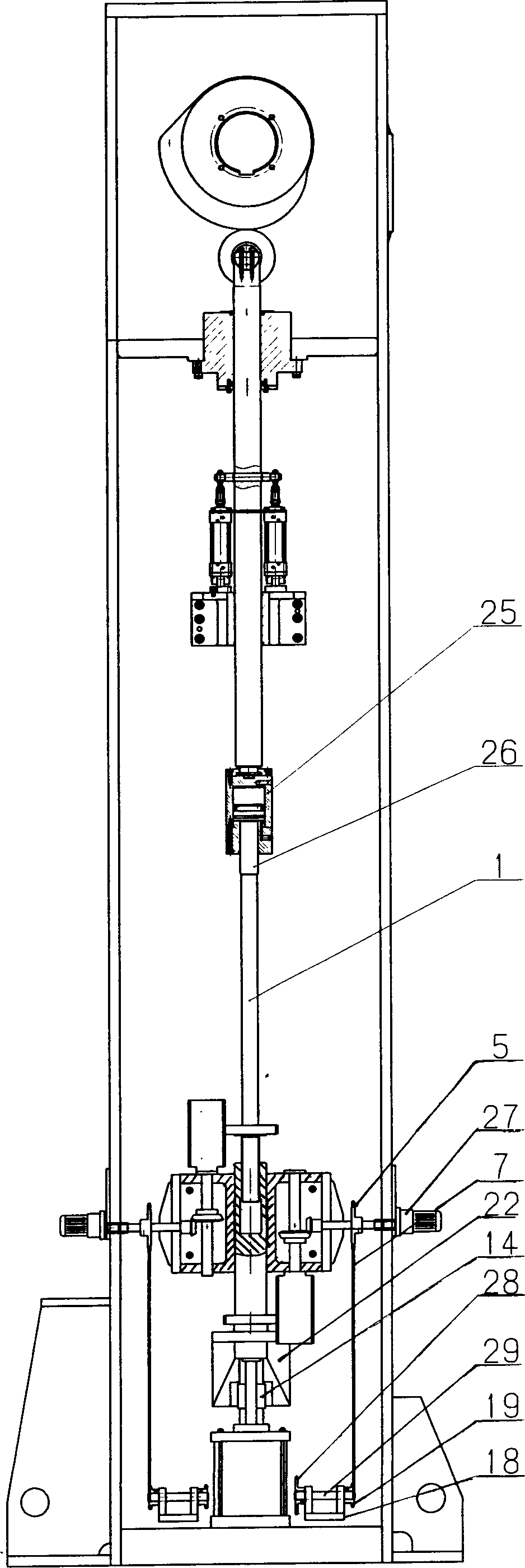

[0015] The hole end of the blind hole in the middle of the adjustment column 13 upper ends has an internal thread, and the end is connected with a driven gear 12, and the lower surface is fixed with a screw pad 11, so that the driven gear 12 can be stopped from moving down, and it can be replaced after long-term work wear.

[0016] The lower end of the adjustment rod 1 is a screw rod, and the outside is connected with a driven gear 2, and the adjustment rod 1 is threaded into an integral lower pressure rod through the lower end screw rod and the blind hole end of the adjustment column 13.

[0017] The two gear racks 4 are respectively symmetrically fixed on the outer surfaces of the two side walls of the frame 24 with screws, and the adjustment column 13 on the lower pressure rod is installed in the middle cavity of the gear rack 4, and the upper and lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com