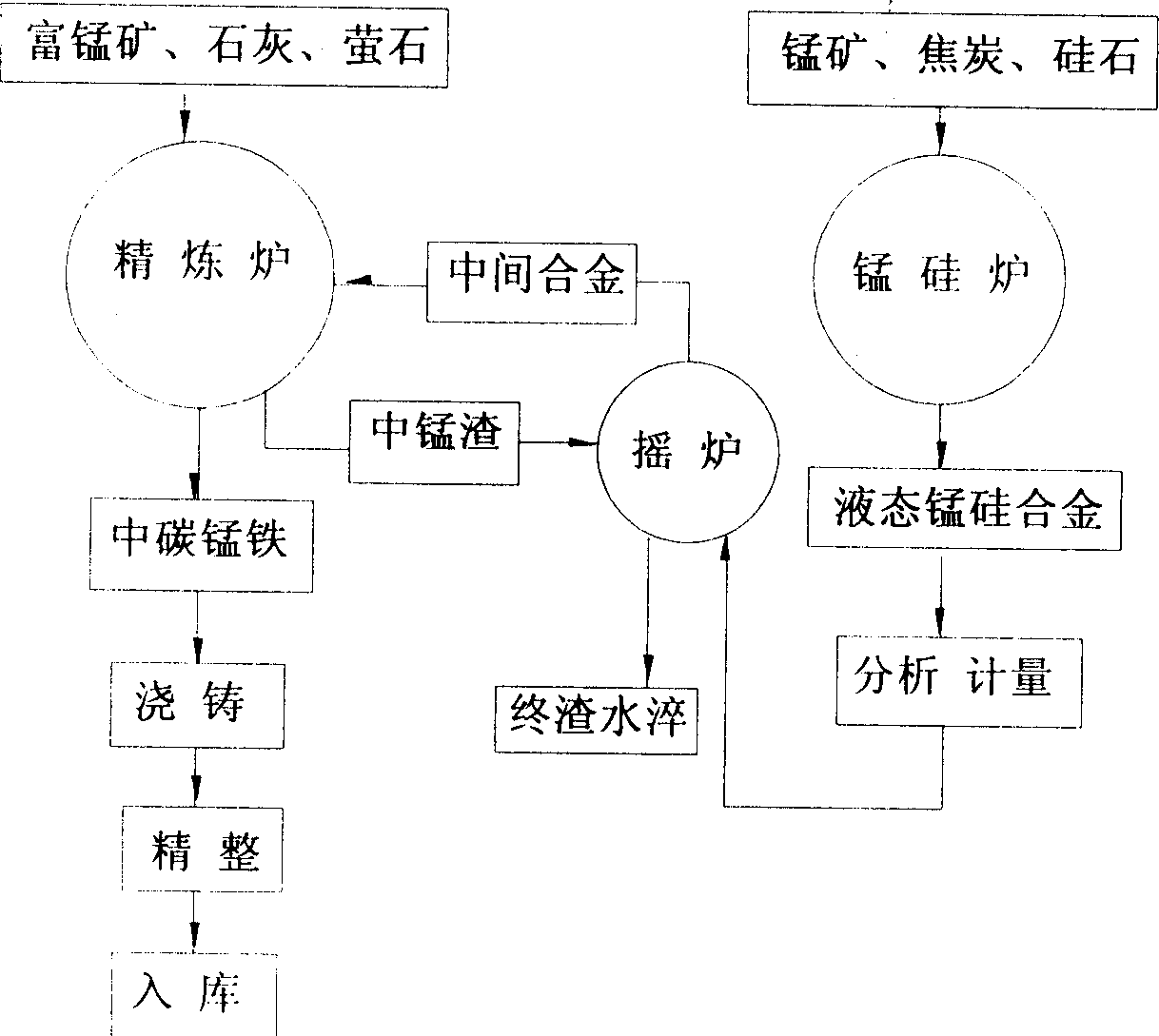

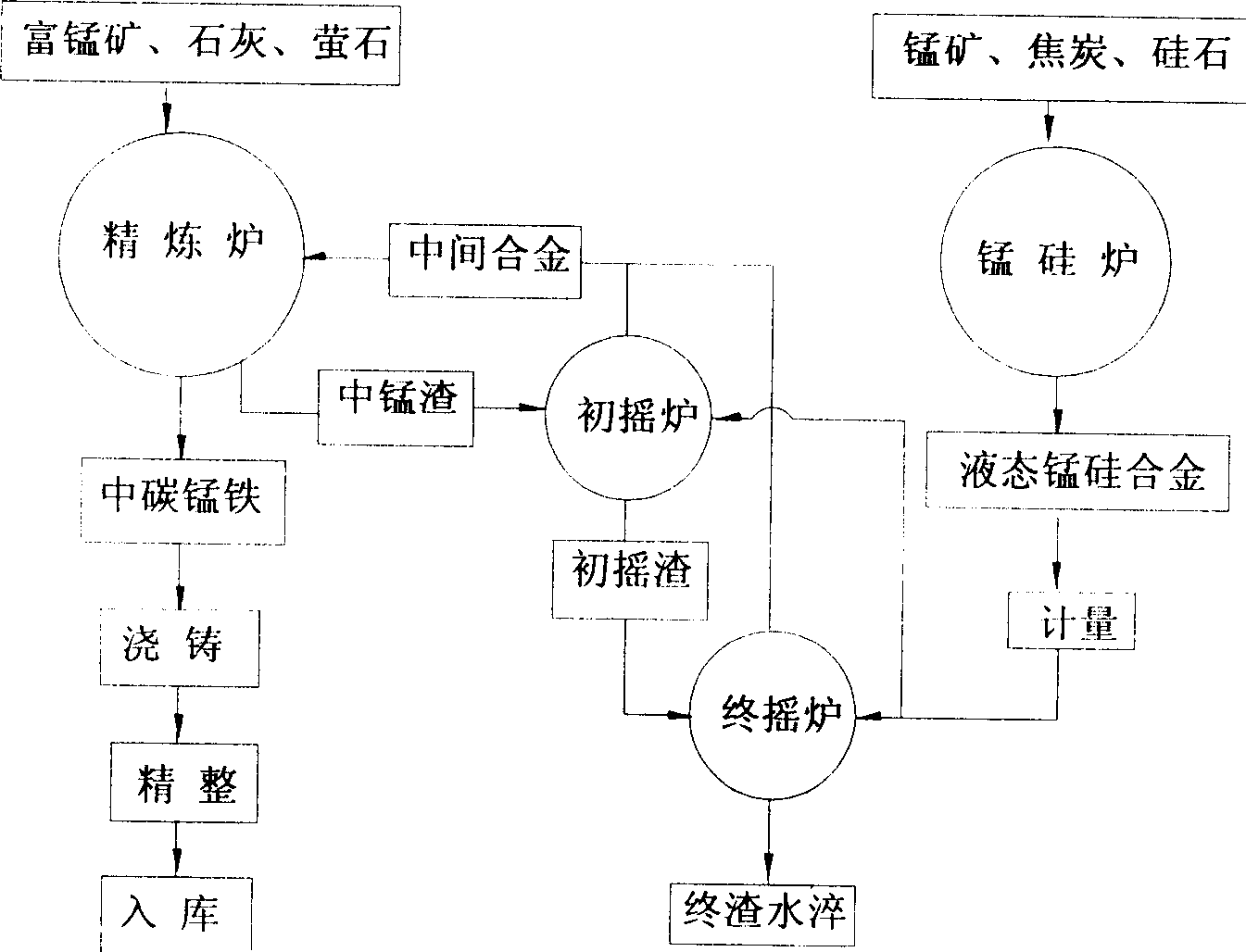

Producing medium carbon magnganese iron by duplexing rocking furnace method

A medium-carbon ferromanganese and shaking furnace technology is applied in the production field of manganese-based ferroalloy products and can solve the problems of unstable manganese content in the final slag.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Manganese ore, coke and silica are added to the manganese silicon furnace. The composition of manganese ore is: Mn30, SiO 2 23.33, Fe3.03, CaO10.46, Al 2 o 3 1.2, MgO2.89; 80% fixed carbon of coke; SiO of silica 2 More than 98%, the above materials are smelted to obtain liquid manganese-silicon alloy, the composition is (weight ratio): Mn67, Si20, Fe11, C1.2, P0.2.

[0018] Add 3286 kg of manganese-rich ore to the refining furnace, the composition is (weight ratio): Mn42, Fe3.1, CaO4.1, SiO 2 7.2, add 3700 kg of lime (CaO greater than 85) and 25 kg of fluorite to control the alkalinity of 1.3. After melting, add the pre-refined liquid intermediate alloy returned from the initial shaking furnace and the final shaking furnace, and then add 1410 to the refining furnace. One kilogram of manganese-rich ore is refined by increasing manganese and reducing silicon, and refining is carried out according to the existing method.

[0019] The refining furnace and manganese-sil...

example 2~4

[0027] According to the same technological process of embodiment 1, the manganese-rich ore / liquid manganese-silicon alloy is 1: 1.1, the manganese-silicon alloy composition is: Mn67, Si20, Fe11, C1.2, and the liquid manganese-silicon alloy is added respectively with 1 / 2 of the total amount The initial shaking furnace and the final shaking furnace; both the initial shaking furnace and the final shaking furnace run at 60 rpm, eccentric distance 40 mm, and run for 12 minutes; The manganese content of the liquid is 20.2, 21.4 and 22.8 respectively, the manganese content of the primary slag, the manganese of the final slag and the manganese content of medium carbon ferromanganese products are shown in Table 1.

[0028] Medium manganese slag contains manganese

[0029] It can be seen from the above table that the manganese content of the medium manganese slag changes, the manganese content of the initial shake slag changes significantly, and the change of the manganese cont...

example 5~10

[0031] According to the same technological process of embodiment 1, both the initial shaking furnace and the final shaking furnace were operated for 15 minutes at 40 rpm and 100 millimeters of eccentricity; the manganese-silicon alloy composition was: Mn67, Si20, Fe11, C1.2; manganese-rich ore The composition is: Mn42, Fe3.1, CaO4.1, SiO 2 7.2; 1 / 2 of the total amount of liquid manganese-silicon alloy is added to the initial shaking furnace and the final shaking furnace respectively. When the ratio of manganese-rich ore / liquid manganese-silicon alloy is 1:0.7-1.2, the initial shaking slag contains manganese and the final shaking slag contains manganese and medium carbon ferromanganese products containing manganese, see Table 2.

[0032] Manganese-rich ore / liquid manganese-silicon alloy

[0033] When the ratio of manganese-rich ore / liquid manganese-silicon alloy is 1:0.7 and 1:0.8, the amount of Si in the liquid manganese-silicon alloy is obviously not enough to reduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com