Electrode wire material and solar battery having connection lead formed of the wire material

A technology of solar cells and wires, applied in circuits, welding media, photovoltaic power generation, etc., can solve the problems of connecting wires falling off, poor soldering, insufficient heat conduction, etc., achieve firm connection, not easy to fall off, and improve solderability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

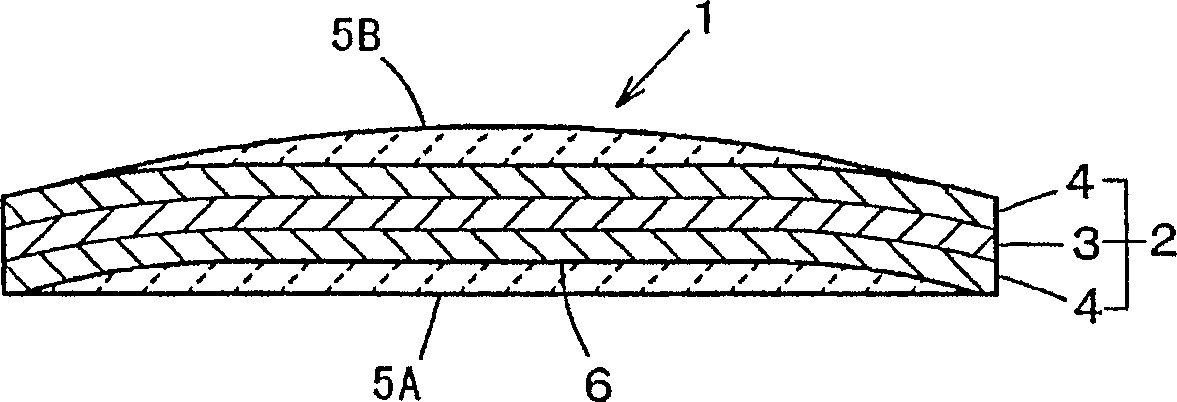

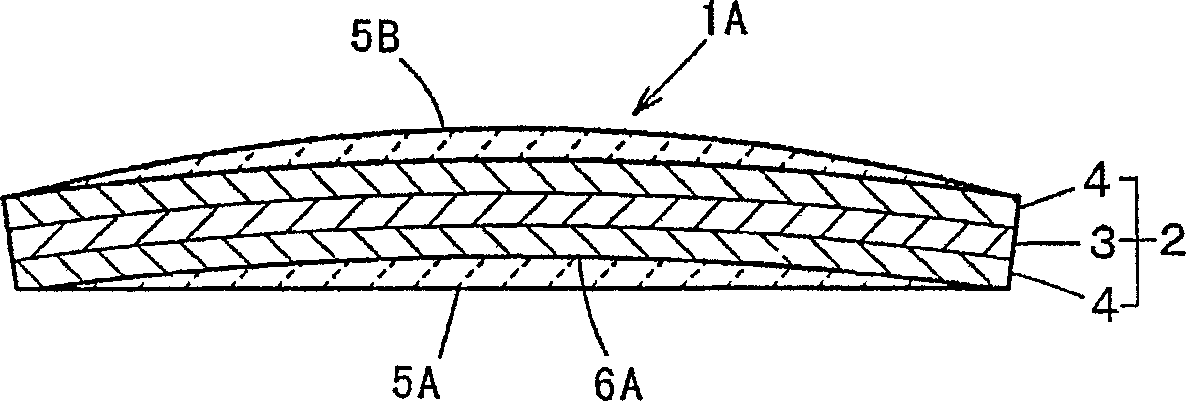

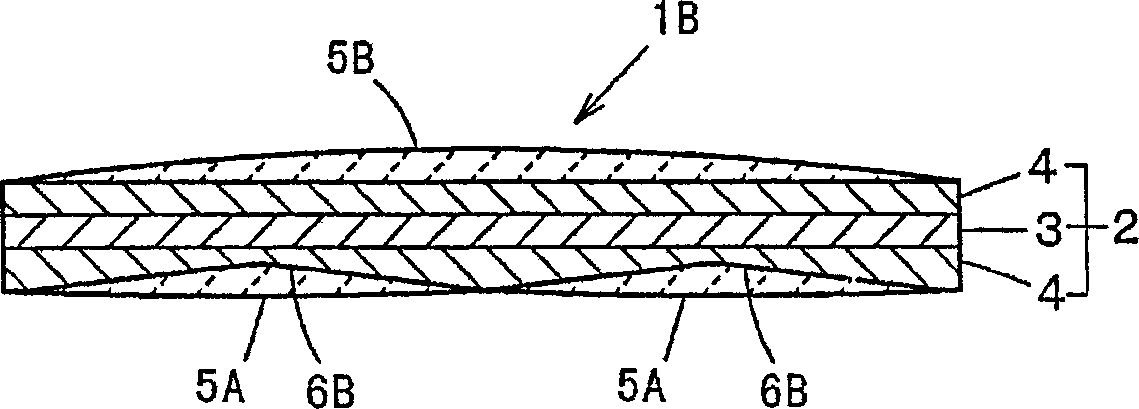

[0041] A cover material (thickness 0.18 mm) in which a 60 μm copper layer was laminated on both surfaces of an intermediate layer made of Invar (Fe-36.5 mass % Ni) and having a thickness of 60 μm was prepared. Using the covering material as a raw material, a strip with a width of 2 mm was produced with a cutter, and the core material of the example with a length of 40 mm was cut from the strip. When cutting, adjust the interval of the rotating blades, such as figure 1 As shown, bending processing was performed to the width direction edge part of a core material, and the cross-sectional shape of the core material was processed into a disk shape. When the cross-sectional shape was observed with an optical microscope (200 times magnification), the maximum depth of the concave portion formed on the concave side of the core material was about 20 μm, and the opening width was about 95% of the core material width. On the other hand, a comparative example core material with a length...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| coefficient of thermal expansion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com