Process flow of heat exchanging refined fluid

A technological process and semen technology, which is applied to the technological process field of semen heat exchange, can solve the problems of high technical requirements for reversing valve production, high production cost and operating cost, complicated pipeline structure, etc., and achieves easy and convenient maintenance and operating cost. Low, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

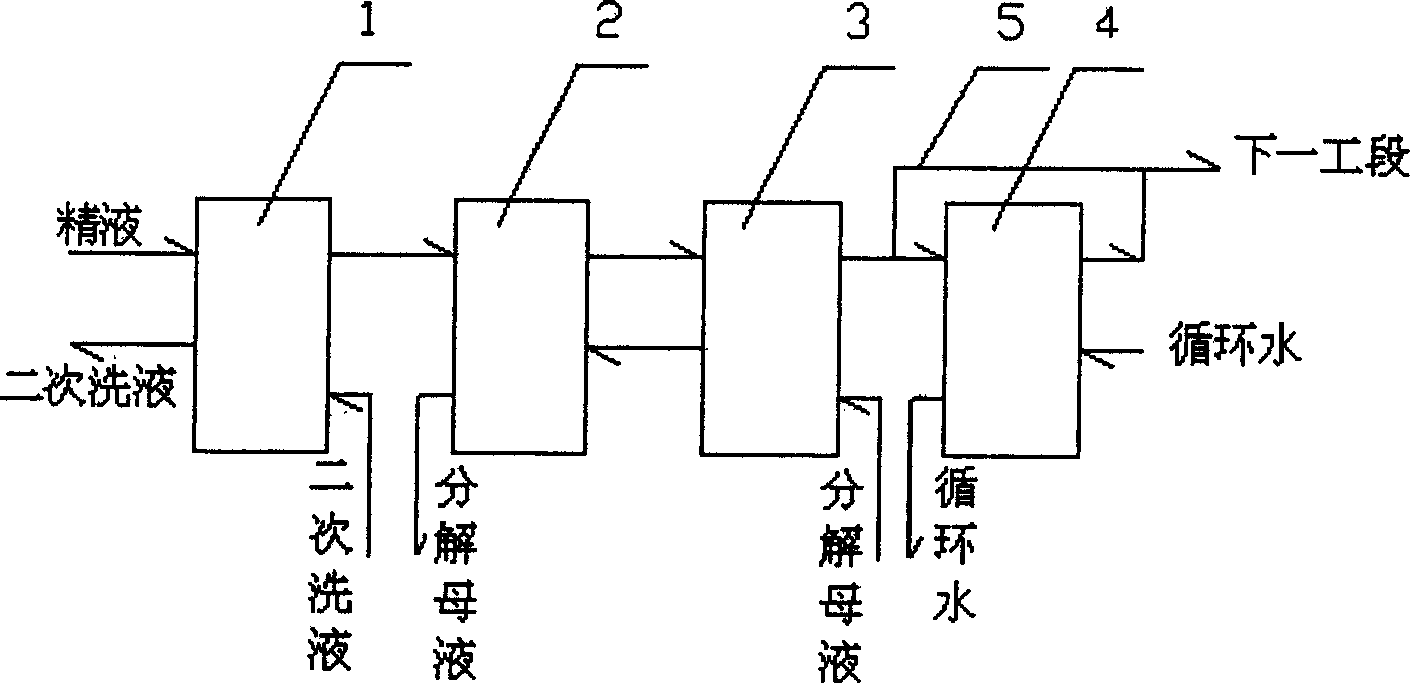

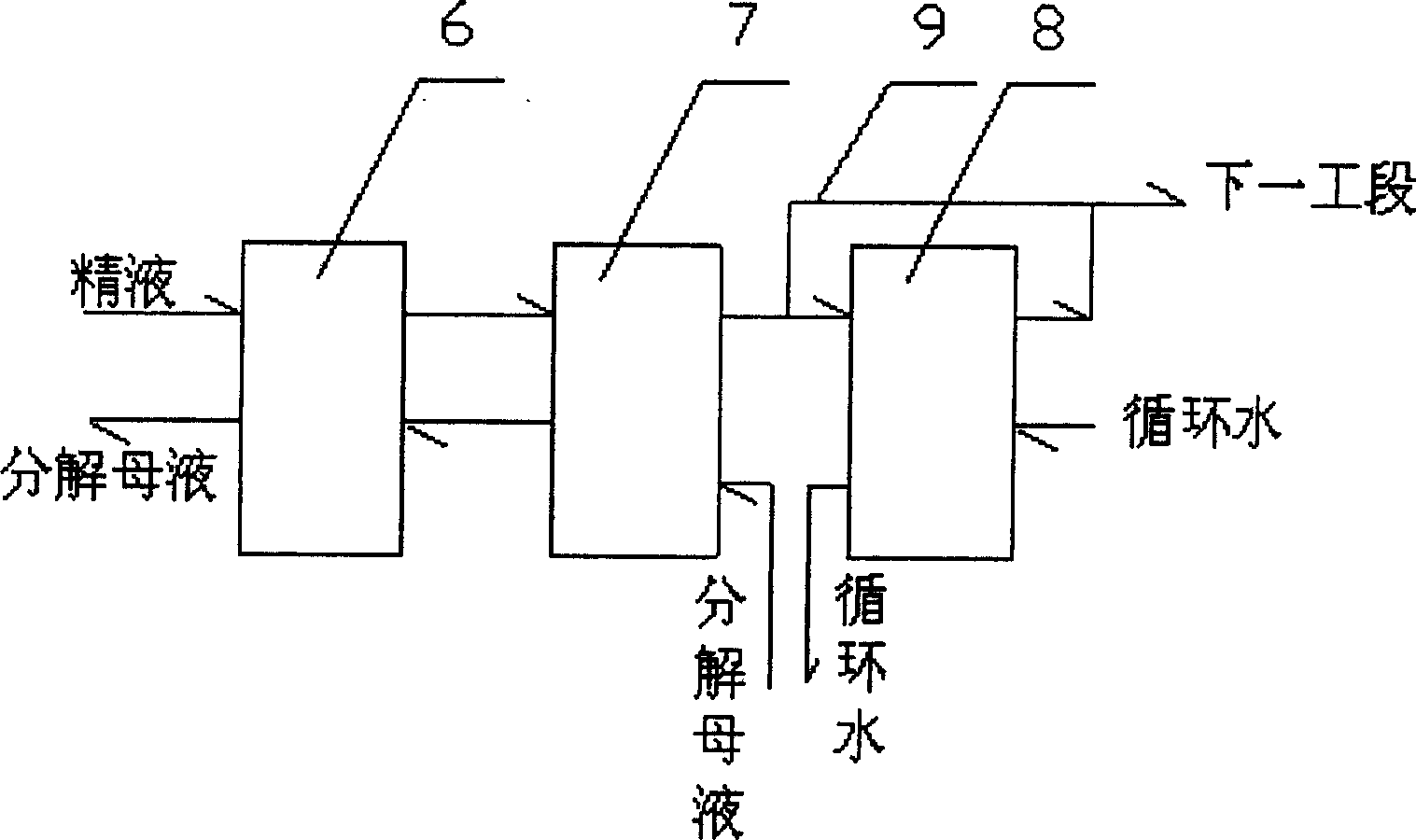

[0010] Embodiments of the present invention: adopt the traditional plate heat exchanger in the prior art and adopt circulating cooling water as cold fluid to carry out heat exchange to hot fluid semen, when adopting plate heat exchanger to carry out heat exchange to hot fluid semen, will need The hot fluid semen for cooling is directly sent to the plate heat exchanger, and the secondary washing liquid or decomposition mother liquor in alumina production is also directly sent to the plate heat exchanger as cold fluid to exchange heat for the hot fluid semen, and then The circulating cooling water is used as the cold fluid to exchange heat with the cooled hot fluid semen.

[0011] In order to achieve a better heat exchange effect, when using the secondary washing liquid and decomposed mother liquor as the cold fluid to exchange heat with the hot fluid semen, three-stage four-plate heat exchangers can be used to exchange heat for the semen, such as figure 1 As shown, that is, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com