Composition for selectively polishing silicon nitride layer and polishing method employing it

A technology of polishing composition and silicon nitride layer, which is applied in the field of polishing, can solve problems such as complex methods and difficult control methods, and achieve the effect of easy waste liquid treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] (d) Preparation method of polishing composition

[0034] The polishing composition of the present invention is prepared by dissolving or dispersing the above-mentioned components in water. The method of dissolving or dispersing is optional, and the order of mixing the components or the method of mixing are not limited.

[0035] The polishing composition of the present invention can be made into a higher concentration stock solution, which can be stored or transported, and can be diluted for use before the actual polishing operation.

[0036] Specifically, the polishing composition of the present invention can be made in the form of a concentrate, that is, when the polishing composition is prepared, the water content is less than the content when the composition is used in the polishing step, and when the concentrate is used in the polishing step , diluted with water to form a polishing composition satisfying the above characteristics.

[0037] Polishing method

[003...

Embodiment

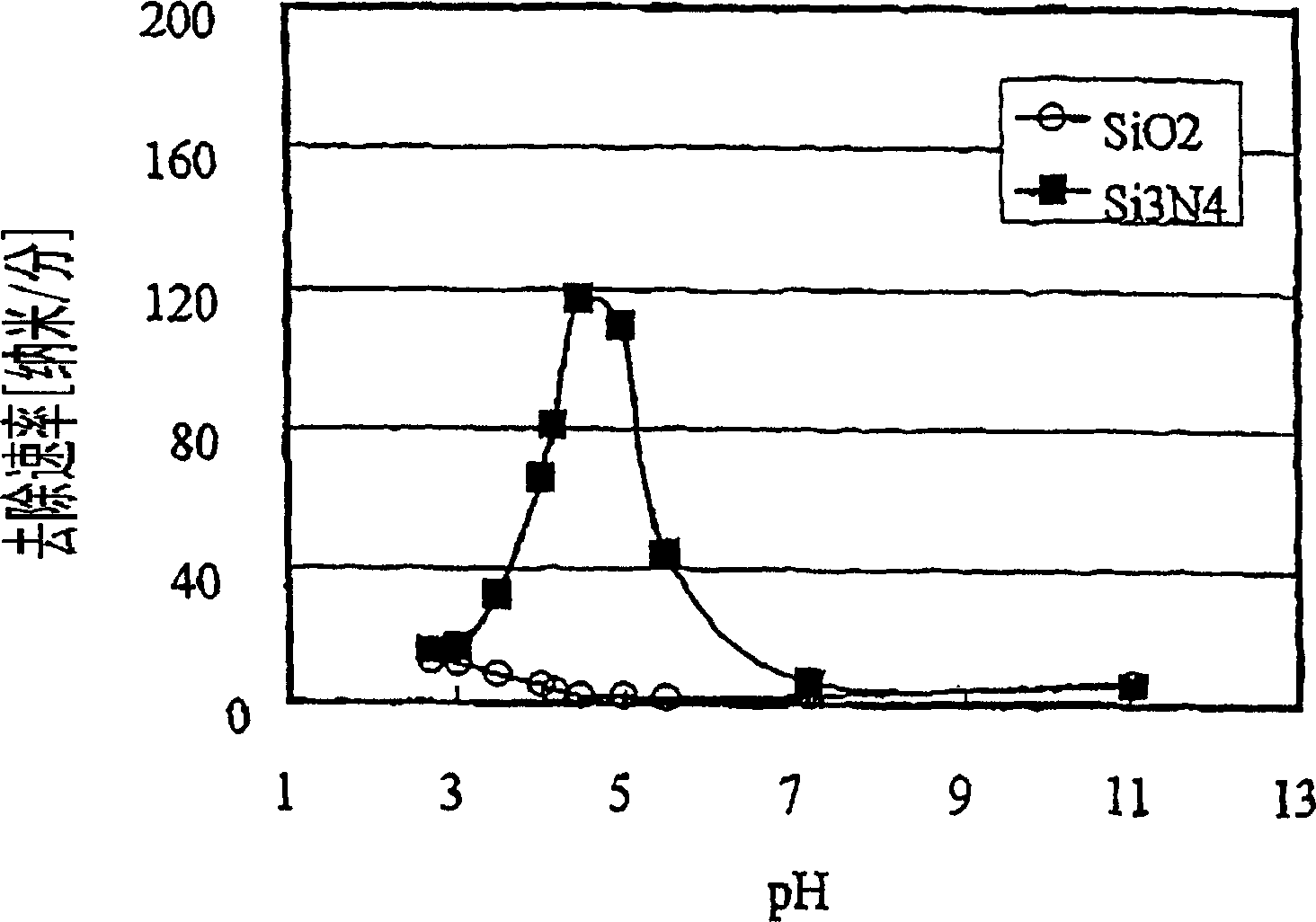

[0041] As an example of a polishing composition satisfying the conditions of the present invention, acetic acid is used as an acid additive and added to an aqueous dispersion containing 5% by weight of abrasive grains with an average particle diameter of 13 nm, such as figure 1 As shown, when the pH value of the liquid phase is adjusted to about 4.5, the optimum adsorption concentration on the abrasive grain surface becomes the equilibrium adsorption concentration. When the polishing pressure is 34.5 kilopascals and the polishing line speed is 42 m / min, the above-mentioned composition is used as the polishing composition, and when polishing, the material removal rate of the silicon nitride layer is 116.7 nm / min, and the oxidation The removal rate of the silicon layer was 1.9 nm / min. This corresponds to a selectivity of about 60, but the chemical etching of both layers by this polishing composition is below the detection limit. For the polishing composition, when the concentra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com