Exhaust gas purifier

一种排气净化装置、收集室的技术,应用在排气装置、消音装置、胶体化学等方向,能够解决流路阻力增大等问题,达到实现外加电压的降低、收集面积扩大、提高去除效率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

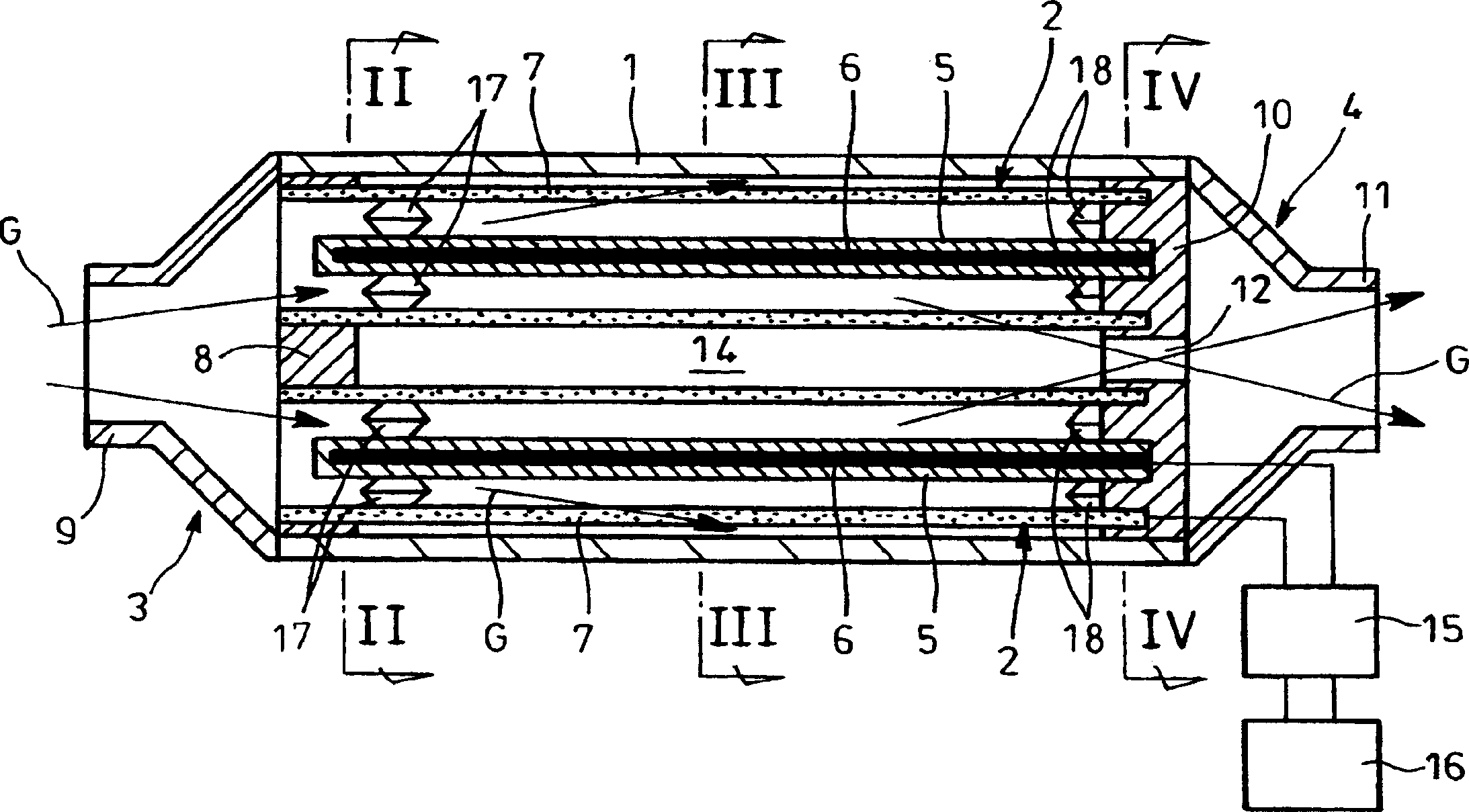

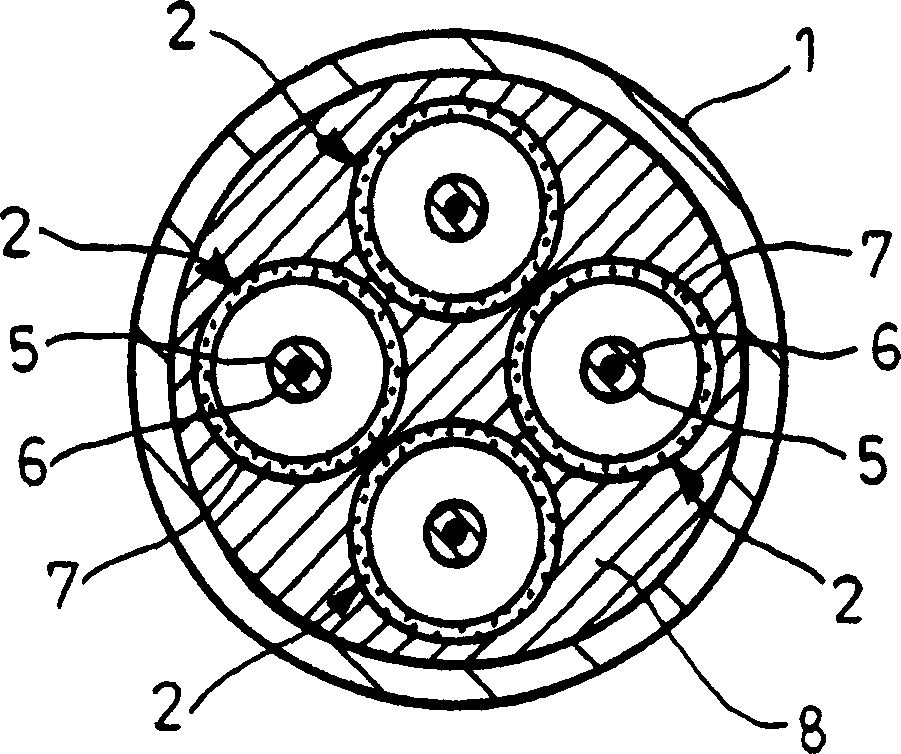

[0058] Figure 1 to Figure 4 The first embodiment of the exhaust purification device of the present invention is shown. This exhaust purification device has a plurality of collection chambers 2 arranged side by side inside a cylindrical casing 1, and an exhaust gas distribution is provided at one end of the casing 1. The mechanism 3 is provided with an exhaust collecting mechanism 4 at the other end of the housing 1.

[0059] The collection chamber 2 has a structure in which a rod-shaped inner electrode 6 whose outer surface is covered with a dielectric material 5 such as ceramics is coaxially arranged inside a cylindrical outer electrode 7 made of a conductive filter that can collect particles.

[0060] As the above-mentioned conductive filter, there is a form in which fibrous metals are laminated and sintered to be integrated, a form in which a sintered body of metal powder and a fine metal mesh are laminated and sintered, or by Sintering is a form in which metal powder is plac...

Embodiment 2

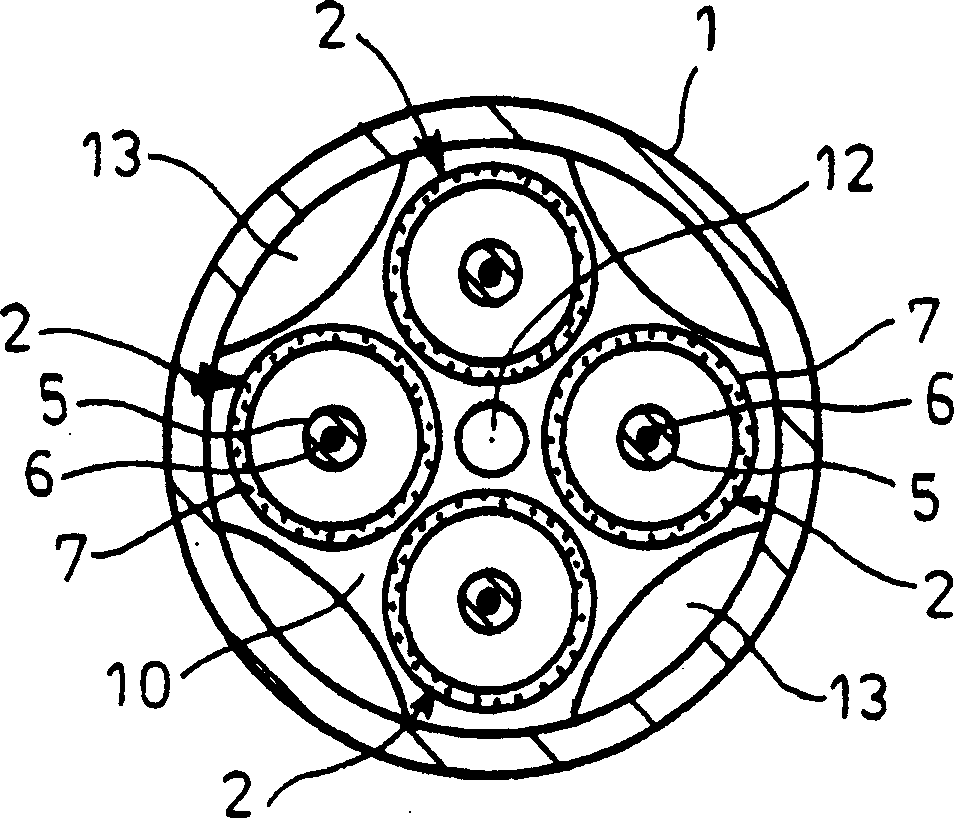

[0076] Figure 5 to Figure 8 The second embodiment of the exhaust purification device of the present invention is shown. This exhaust purification device has a plurality of collection chambers 22 arranged side by side inside a cylindrical casing 21, and an exhaust gas distribution is provided at one end of the casing 21 The mechanism 23 is provided with an exhaust collecting mechanism 24 at the other end of the housing 21.

[0077] The collection chamber 22 has a structure in which a cylindrical outer electrode 27 composed of a conductive filter capable of collecting particulates is coaxially arranged inside a cylindrical outer electrode 26 whose inner surface is covered with a dielectric material 25 such as ceramics.

[0078] The exhaust distribution mechanism 23 is composed of a support plate 28, a plunger 29, and an inlet 30. The support plate 28 is closely attached to the entire outer surface of one end of the outer electrode 26 of each collection chamber 22, and is closely a...

Embodiment 3

[0089] Figure 9 to Figure 12 The third embodiment of the exhaust purification device of the present invention is shown. This exhaust purification device has a plurality of collection chambers 42 arranged side by side inside a cylindrical casing 41, and an exhaust gas distribution is provided at one end of the casing 41 The mechanism 43 is provided with an exhaust collecting mechanism 44 at the other end of the housing 41.

[0090] The collection chamber 42 has a cylindrical dielectric 46 coaxially arranged inside a cylindrical outer electrode 45 composed of a conductive filter that can collect particles, and a cylindrical shape composed of a conductive filter that can collect particles The inner electrode 47 is coaxially arranged inside the dielectric body 46 described above.

[0091] The exhaust distribution mechanism 43 is composed of a support plate 48, a plunger 49, and an inlet 50. The support plate 48 is closely attached to the entire outer surface of one end of the outer e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com