Magnesium metaphosphorate production process

A production process and technology of magnesium metaphosphate, applied in the directions of phosphorus compounds, inorganic chemistry, non-metallic elements, etc., can solve the problems of complex production process, high cost, low yield, etc., and achieve simple production process, low cost, and yield. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Production technology principle of the present invention is as follows:

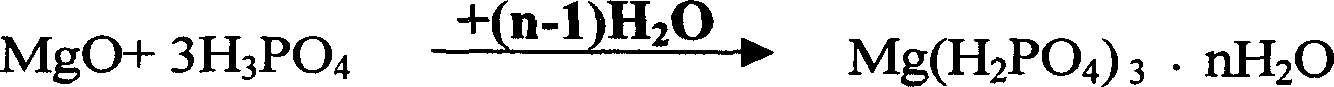

[0023] 1. Convert MgO to 4MgCO 3 ·Mg(OH) 2 ·5H 2 O and H 3 PO 4 react to form water-soluble Mg(H 2 PO 4 ) 3 ·nH 2 O. The chemical reaction formula is as follows:

[0024]

[0025] 2. The water-soluble Mg(H 2 PO 4 ) 3 ·nH 2 O in less excess H 3 PO 4 In the presence of high-temperature spray drying, the extramolecular crystal water will be lost first, and anhydrous Mg(H 2 PO 4 ) 2 . The chemical reaction formula is as follows:

[0026]

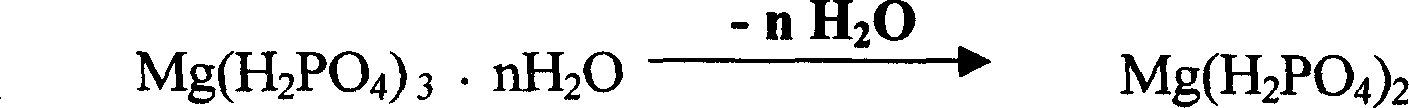

[0027] 3. Remove the "constituent water" in the molecule. The chemical reaction formula is as follows:

[0028]

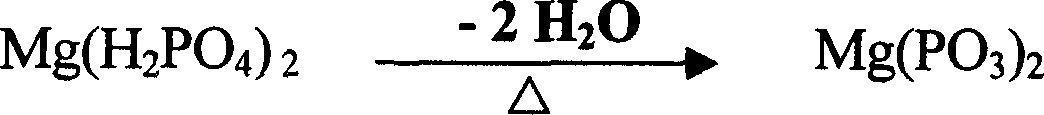

[0029] 4. The [Mg(PO 3 ) 2 ] n . The chemical reaction formula is as follows:

[0030]

[0031] Wherein n=3~6.

[0032] Concrete production technique of the present invention is as follows:

[0033] 1. Take the raw material MgO or 4MgCO 3 ·Mg(OH) 2 ·5H 2 O, placed in a 1500L stainless steel react...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dehydration rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com