Wind-driven hydraulic plunger water raising method and apparatus

A hydraulic column and pneumatic technology, applied in the field of pneumatic hydraulic plunger pumping method and device, can solve the problems of low work efficiency, small head, large investment, etc., and achieve high work efficiency, high water delivery pressure, and water delivery flow big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing:

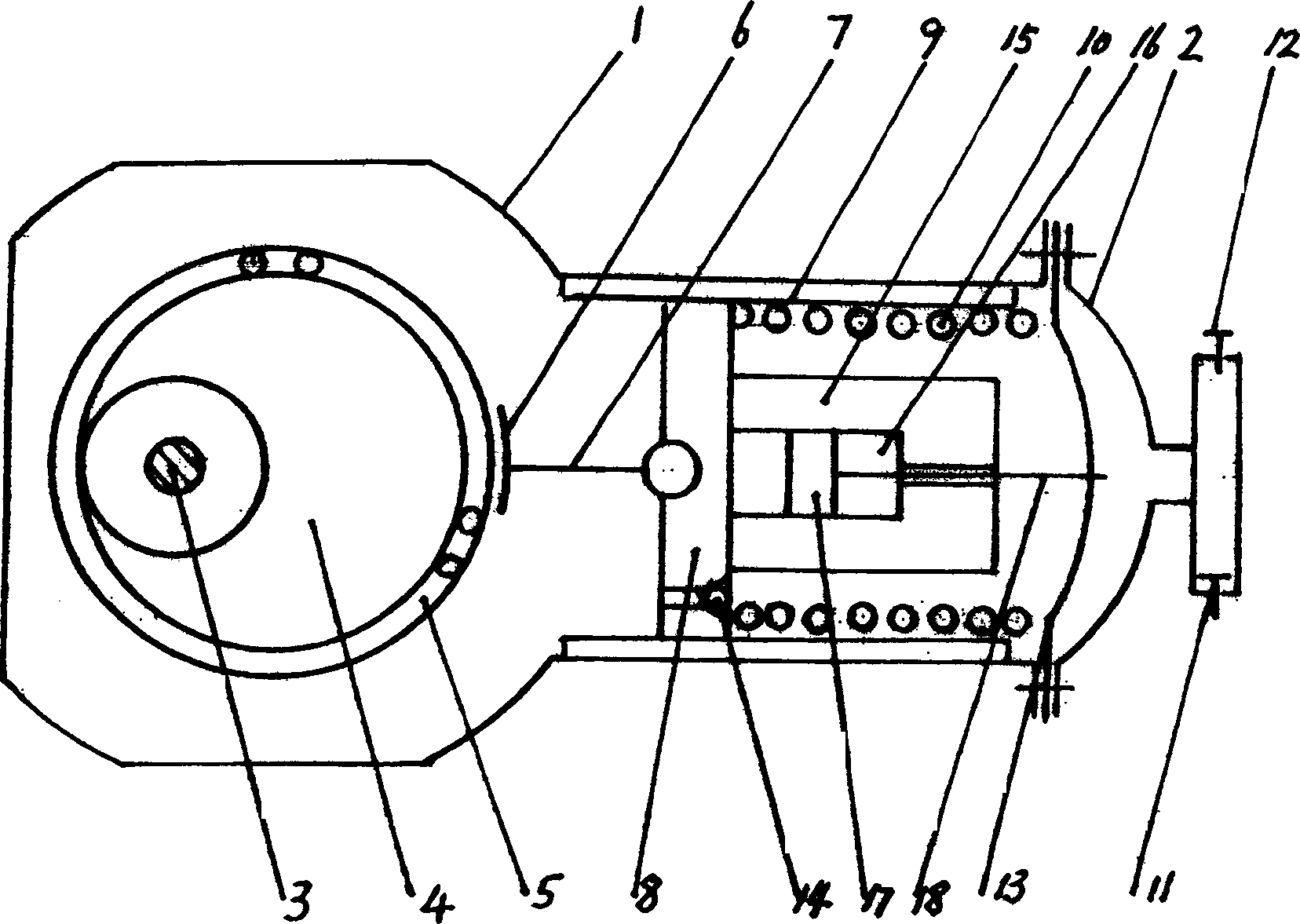

[0015] A pneumatic hydraulic plunger pumping method is as follows: using wind energy to drive the wind blades to rotate to generate power, the power changes the transmission direction through the transmission shaft and the transmission, and then the output shaft passes through the automatic clutch device, the universal adjustment shaft and the hydraulic plunger diaphragm pumping method. The input shaft of the pump is connected, and the hydraulic plunger diaphragm pump pumps water.

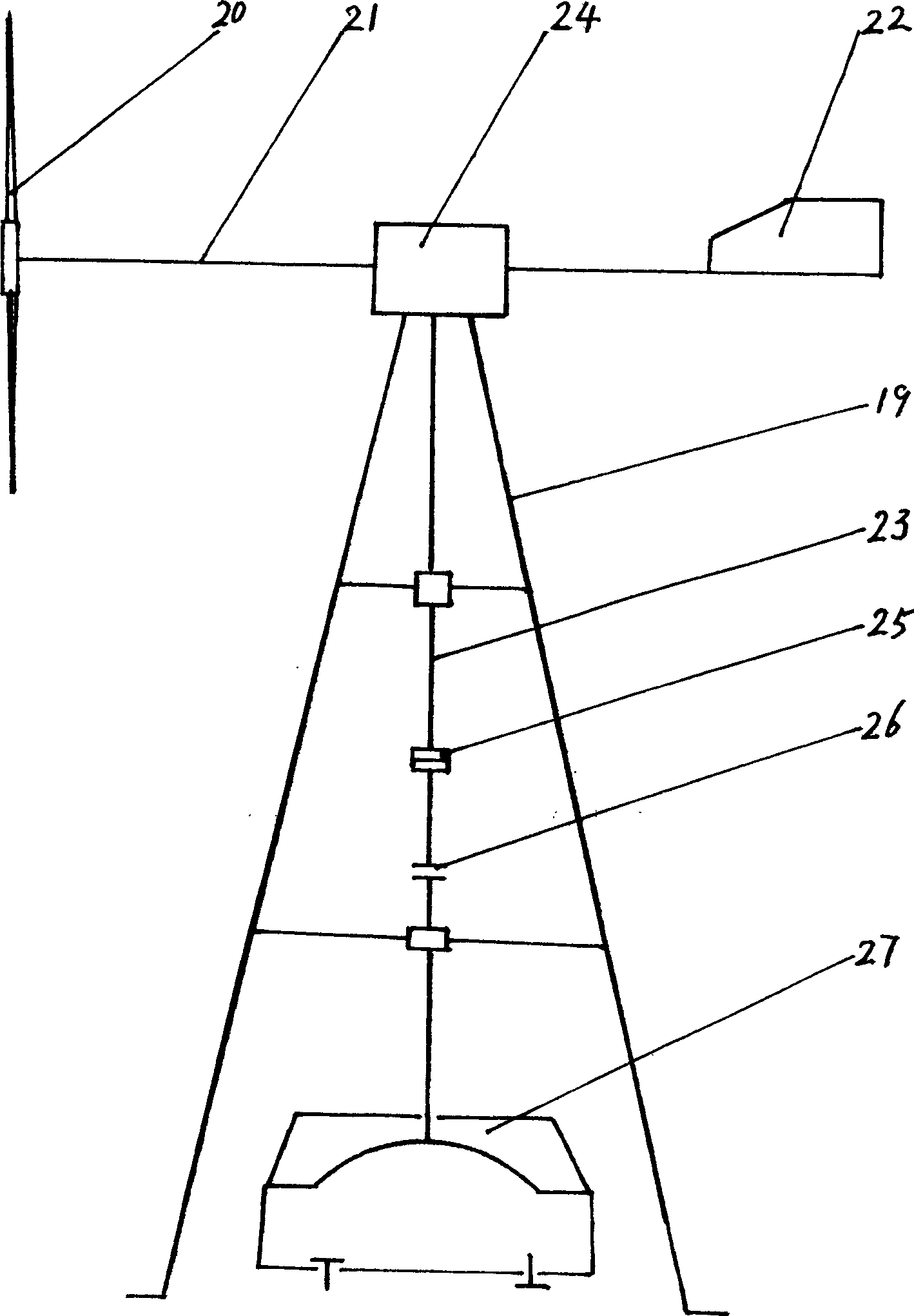

[0016] A wind-driven hydraulic plunger pumping device is composed of a wind energy conversion mechanism and a hydraulic plunger diaphragm type water pump. The wind energy conversion mechanism is provided with a support frame 19, fan blades 20, a transmission shaft 21, a wind direction adjustment piece 22, a support frame 19, The structure of wind blade 20, power transmission shaft 21, wind direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com