Resonant sensor assembly

A resonant sensor and sensor technology, which is applied to instruments, the measurement of the force of the piezoelectric device, and the measurement of fluid pressure through electromagnetic elements, can solve the problems of expensive labor, intensive, and difficult to realize automation of resonators, and achieve high quality. Factor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

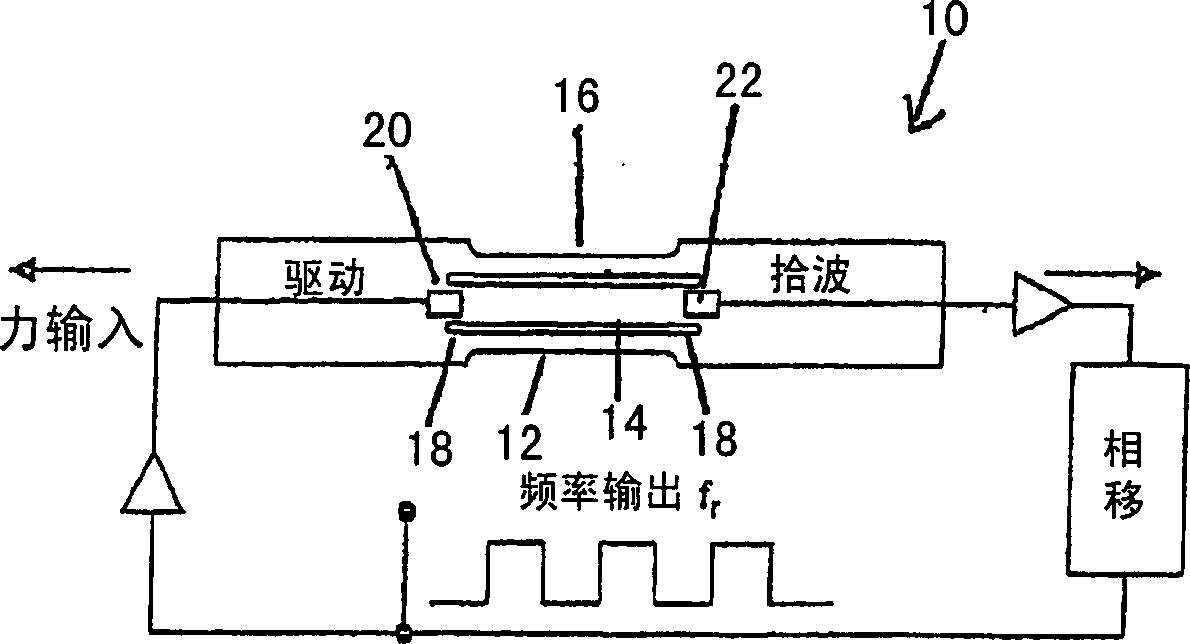

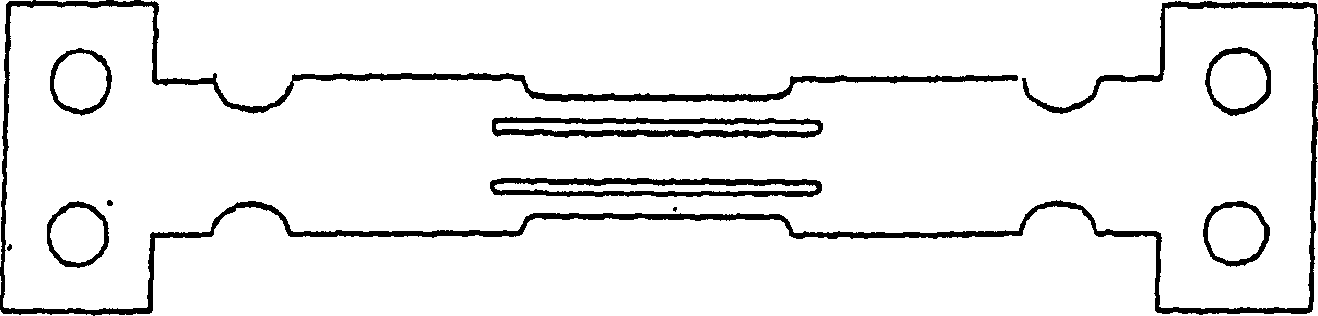

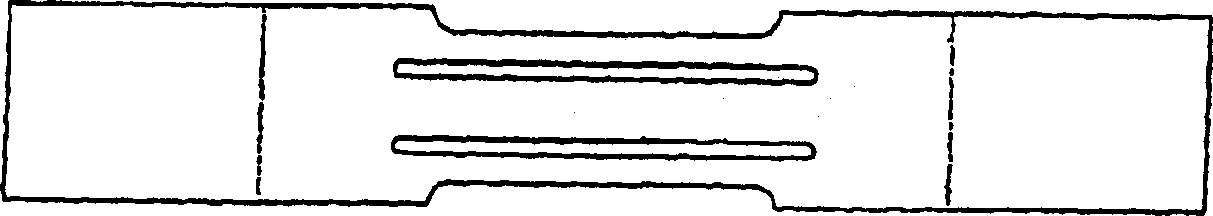

[0047] The preferred embodiment described herein provides a metallic, silicon or ceramic triplet beam resonator with thick film piezoelectric elements for driving and detecting vibrations. In the case of metal resonators, the substrate of the preferred embodiment is fabricated by means of photochemical etching techniques on both sides, and the thick film piezoelectric elements are provided by standard screen printing processes. An embodiment of the resonator constructed and tested had a length of 15.5mm, an overall width of 7mm, and had a characteristic mode with a quality factor of 3100 at 7.2kHz. The triplet beam resonator can be described as having a tuning fork structure with a thick film piezoelectric driver and pickup element.

[0048] refer to figure 1 , the triplet beam resonator embodiment shown is provided with printed thick film piezoelectric drivers and pickups. A thick piezoelectric film is screen printed in batches at the correct position on the tine of the res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com