Beam forming network with continuously variable differential phase

A differential phase and variable technology, applied to waveguide devices, antennas, circuits, etc., can solve the problems of limited practical application, inconvenient processing, and complexity, and achieve suppression of passive intermodulation products, low cost, and small size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

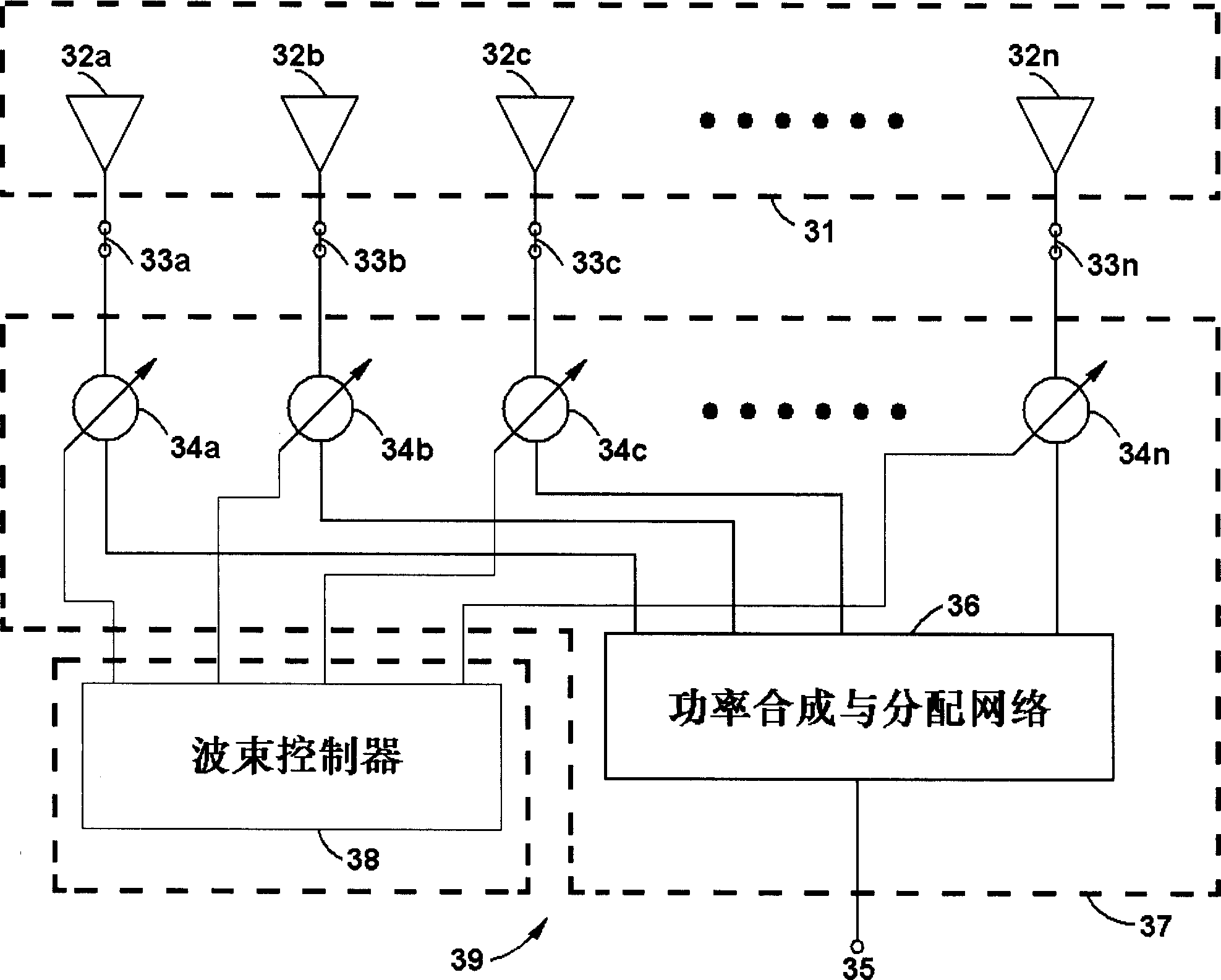

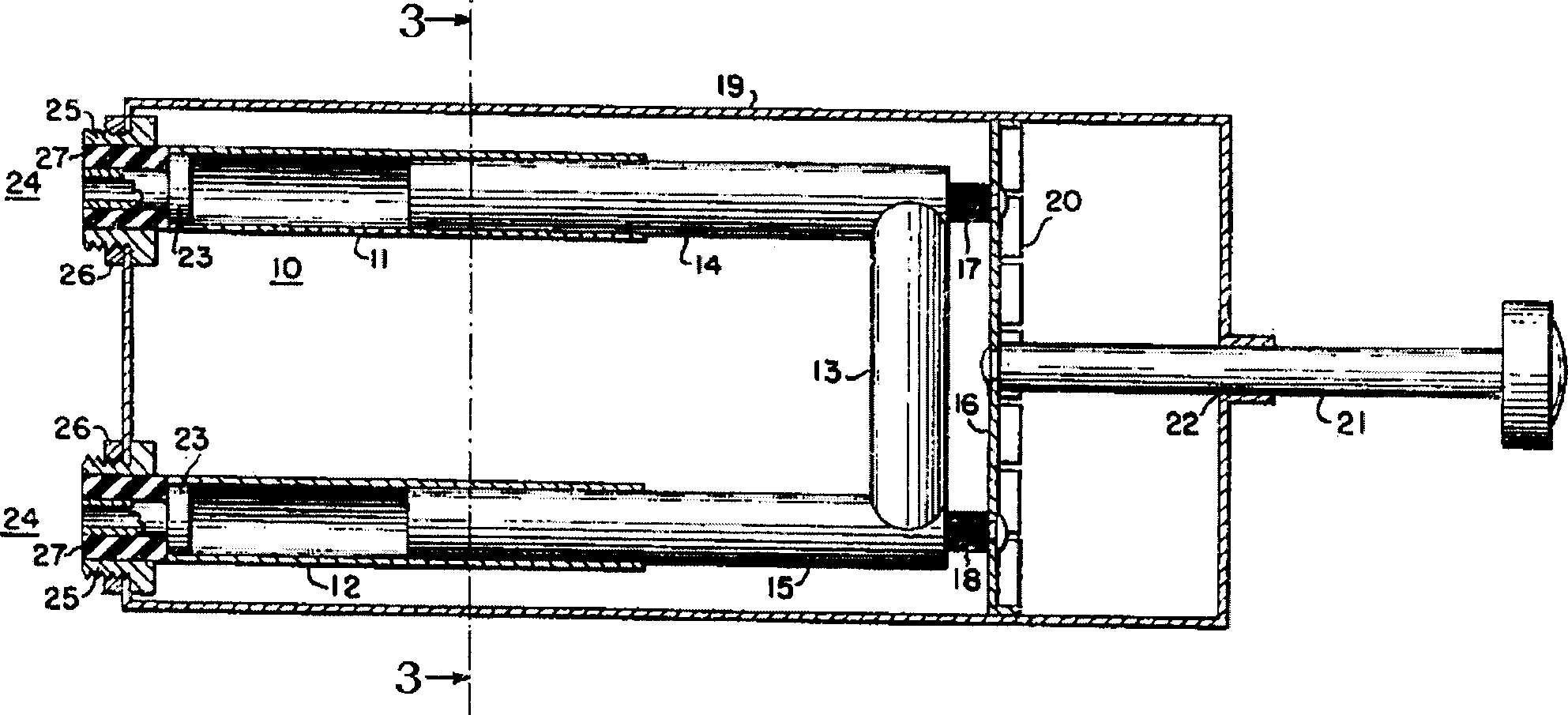

[0043] see Figure 6 and Figure 7 In the present invention, the differential phase continuously variable beamforming network 70 is integrally designed inside the metal cavity 108 . These include:

[0044] A power splitter group consisting of 4 power splitters, that is, a front power splitter 71, a main power splitter 72, and a slave power splitter 73, 74; 4 phase shifters 81, 82, 83, 84; an insulator 111; a dielectric rod 110; 6 external ports 60, 61, 62, 63, 64, 65.

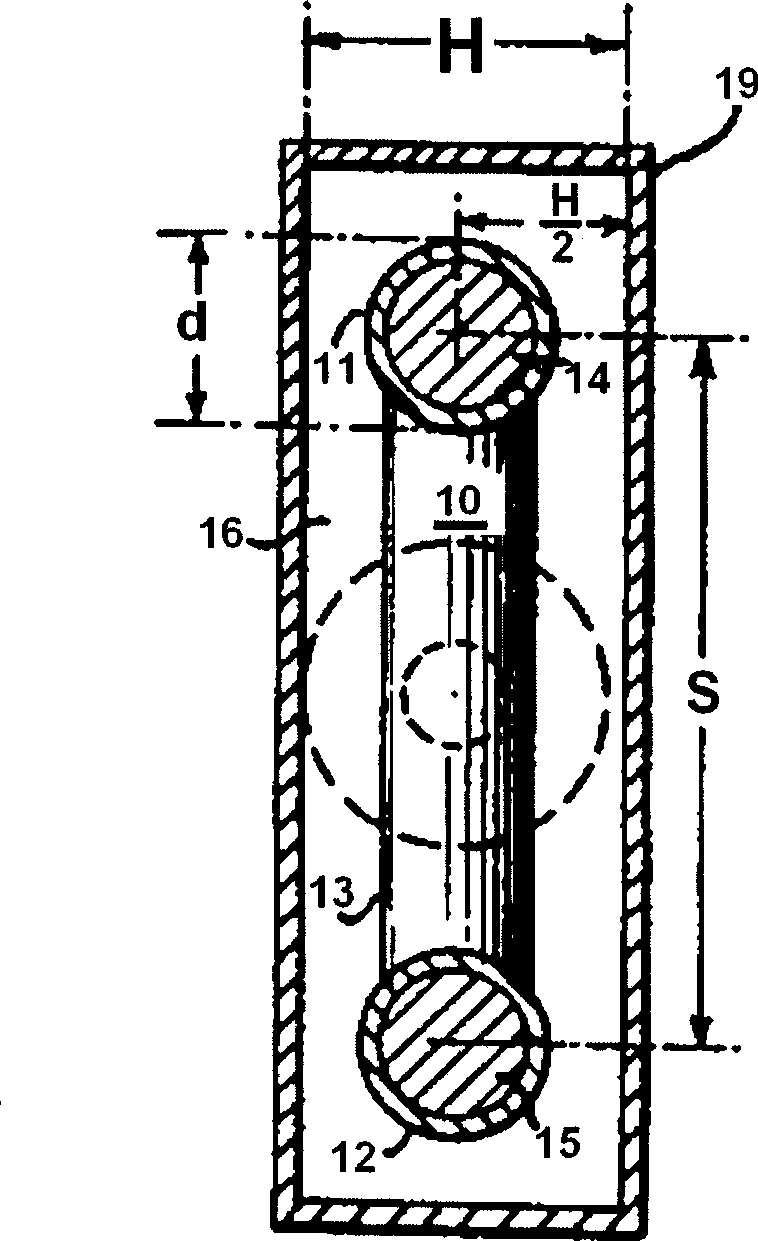

[0045] In the power splitter group, the pre-power splitter 71 is made up of striplines 221, 222, 223, the stripline 221 is used as a synthesis end, the striplines 222, 223 are used as an output end, and the signal distribution of the stripline 221 To the output of the two arms of the striplines 222, 223, as we all know, the respective length and width of the striplines 221, 222, 223 determine the required power distribution ratio, and also determine the impedance matching characteristics on a specific workin...

no. 2 example

[0074] see Figure 10 The improvement of the second embodiment relative to the first embodiment is that: the strip line 221 at the synthesis end of the main power splitter 72 is directly electrically connected with the power synthesis end 601 through a coaxial wire, and the pre-power splitter is discarded. Correspondingly, there are only four power distribution ports left, which are 61, 62, 64, and 65 respectively. In this way, according to the description of the above-mentioned first embodiment, it can be similarly obtained that the differential phases from the power combining terminal 601 to the four power distribution terminals 61, 62, 64, and 65 are -2Δ, -Δ, +Δ, +2Δ in sequence, combining Another pre-power splitter 71 (not shown, refer to Figure 7 ) The 0 differential phase output of the power distribution terminal can also obtain 5 phase shift outputs with differential phases of -2Δ, -Δ, 0, +Δ, +2Δ in sequence. In this way, the original pre-power divider 71 inside the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com