Modularized joint of space manipulator

A technology of modular joints and space manipulators, applied in the direction of manipulators, manufacturing tools, joints, etc., can solve the problems of poor safety reliability and complex structure of space manipulator joints, and achieve the effects of shortening the development cycle, reliable transmission and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

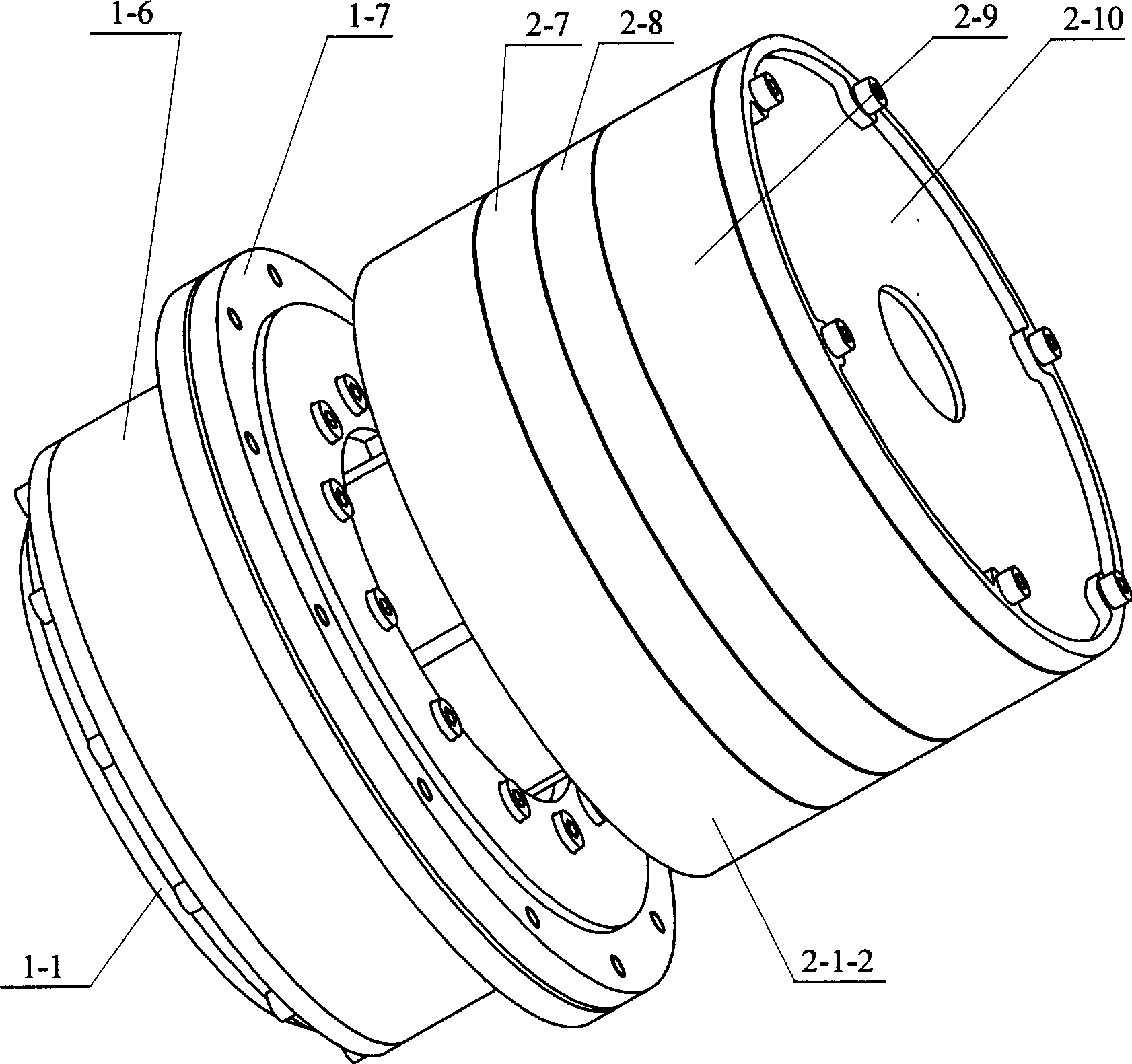

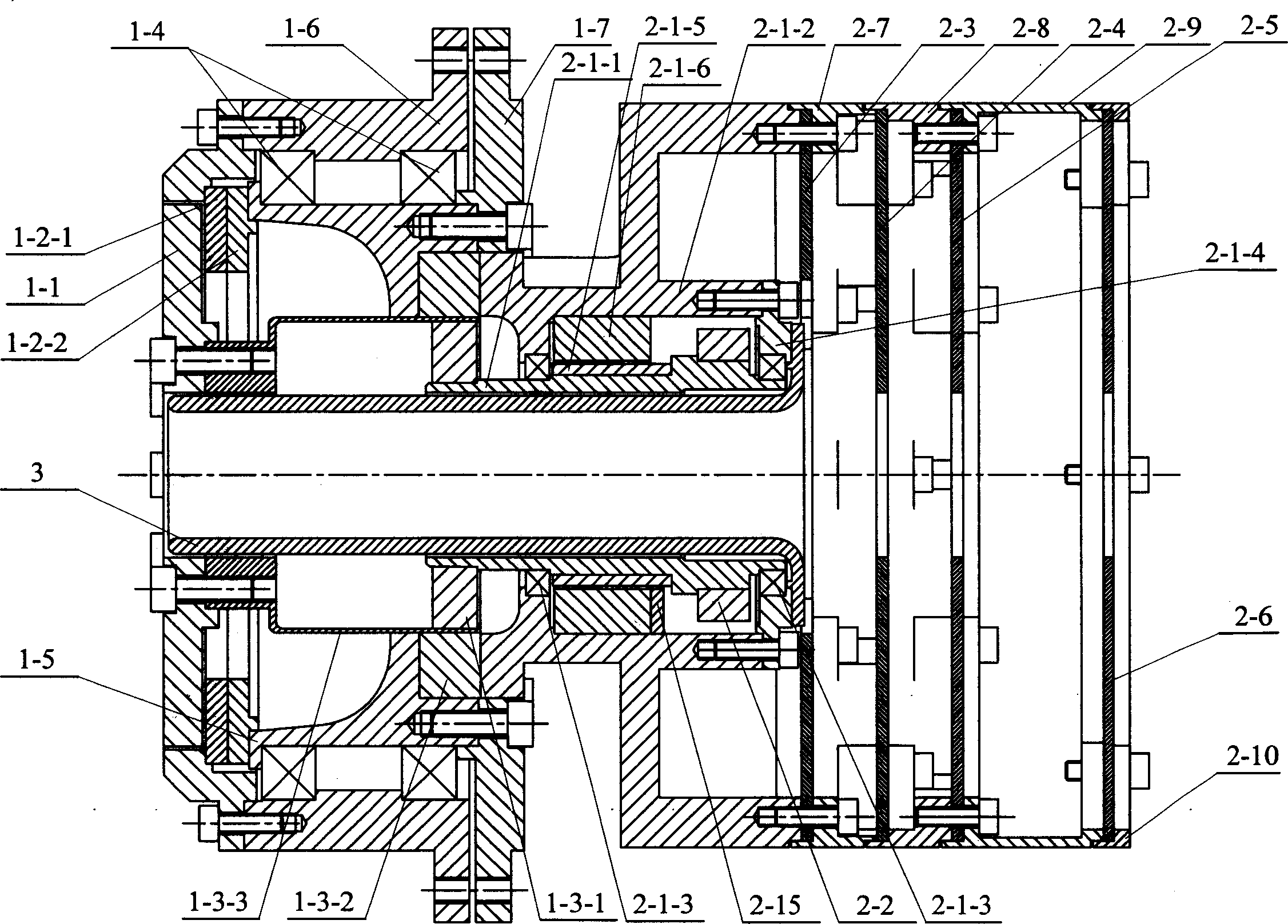

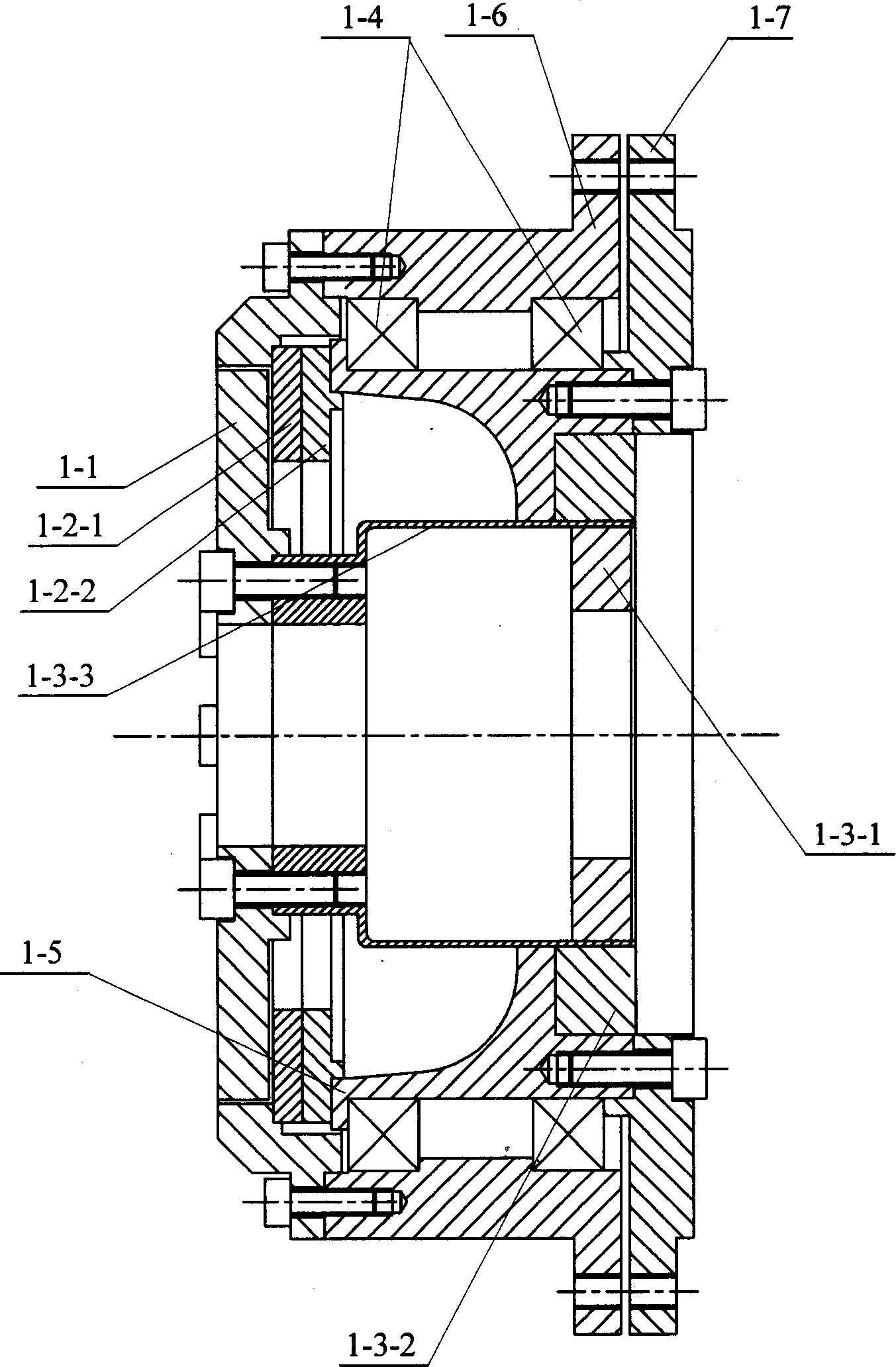

[0007] Specific implementation mode one: combine Figure 1~4 Describe this embodiment, this embodiment is made up of joint mechanism, motor device and sleeve 3; Described joint mechanism is made up of torque sensor 1-1, position sensor, harmonic reducer, bearing 1-4, bearing inner ring seat 1 -5. Bearing outer ring seat 1-6 and connecting flange 1-7, the harmonic reducer is composed of wave generator 1-3-1, rigid wheel 1-3-2 and flexible wheel 1-3- 3, the motor device is composed of a DC brushless motor, a magnetic encoder 2-2, a drive circuit board 2-3, a control circuit board 2-4, a power supply circuit board 2-5, an interface circuit board 2-6, a A bracket 2-7, a second bracket 2-8, a third bracket 2-9 and a pressure ring 2-10, the brushless DC motor is composed of a motor shaft 2-1-1, a motor housing 2-1-2 , motor bearing 2-1-3, end cover 2-1-4, motor rotor 2-1-5 and motor stator 2-1-6; motor casing 2-1-2 is fixed with motor stator 2-1 -6, the motor rotor 2-1-5 is housed...

specific Embodiment approach 2

[0009] Specific implementation mode two: combination figure 2 Describe this embodiment, the difference between this embodiment and the specific embodiment one is: the motor device of this embodiment is also added with a digital Hall sensor 2-15; -1-2 and fixedly connected with the motor stator 2-1-6. Redundant measurement of the motor position: it can be measured separately through the digital Hall sensor 2-15 and the magnetic encoder 2-2, which can improve the reliability of the system. If one is broken, the other can work independently.

specific Embodiment approach 3

[0010] Specific implementation mode three: combination Figure 7-9Describe this embodiment, the torque sensor 1-1 of this embodiment is made up of torque input disc 1-1-1, torque output disc 1-1-2, strain beam, strain gage, four sensor protection beams and four protection pads Composition; the strain beam is composed of a first strain beam 1-1-3-1, a second strain beam 1-1-3-2 and a third strain beam 1-1 uniformly distributed along the circumference of the moment input disc 1-1-1 -3-3 and the fourth strain beam 1-1-3-4, the first strain beam 1-1-3-1, the second strain beam 1-1-3-2, the third strain beam 1-1- 3-3 and the two ends of the fourth strain beam 1-1-3-4 are respectively made into one body with the torque input disc 1-1-1 and the torque output disc 1-1-2, and the strain gauges are respectively pasted on the The first strain gauge 1-1-4-1 and the second strain gauge 1-1-4-2 on the first strain beam 1-1-3-1, pasted on the second strain beam 1-1-3-2 The third strain gau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com