System and method for induction heating of heatable fuser member using ferromagnetic layer

A technology of ferromagnetic layer and heating element, which is applied in the direction of induction heating, induction heating device, electric recording process equipment using charge pattern, etc., can solve the problem of not being the most suitable, and achieve the effect of achieving axial temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

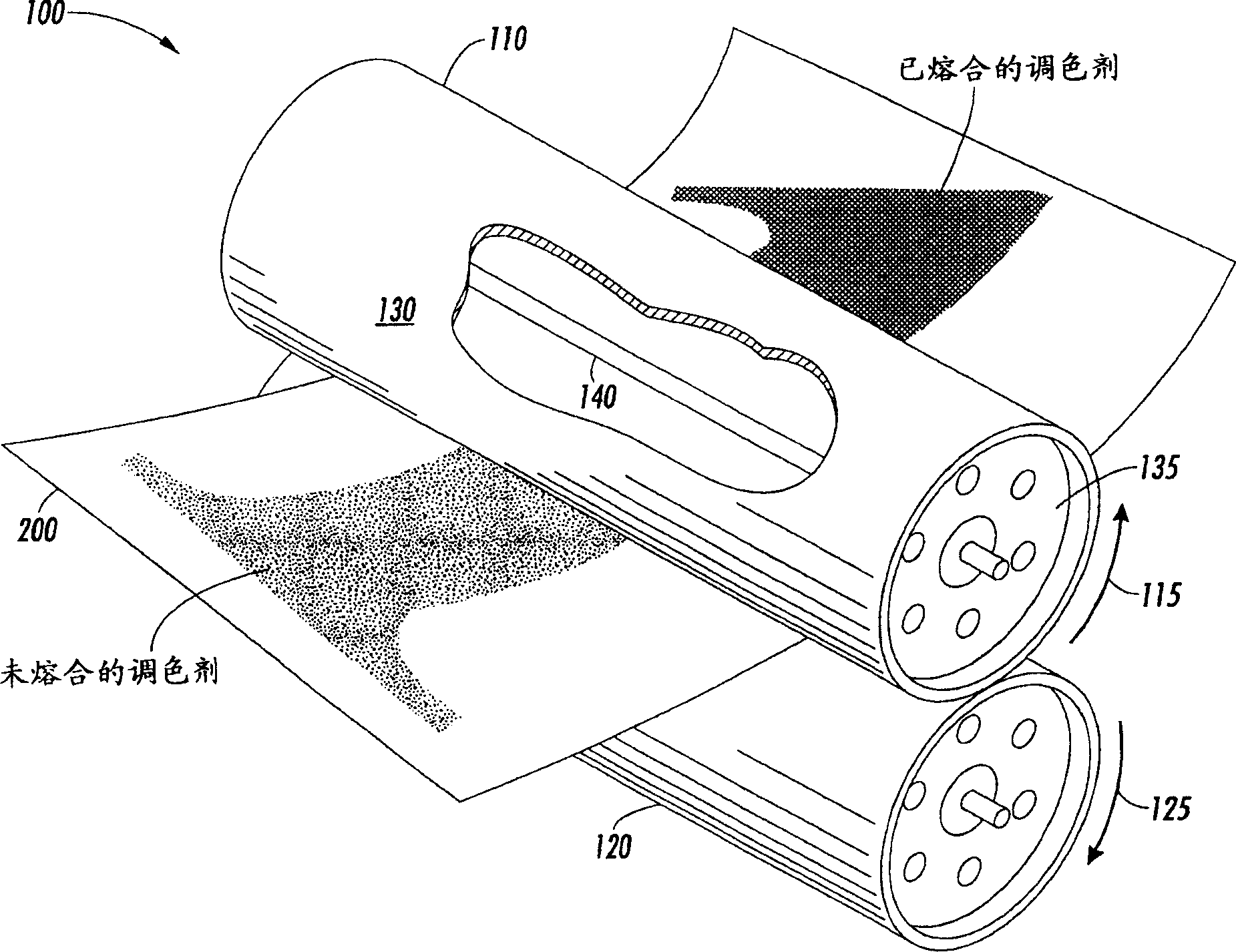

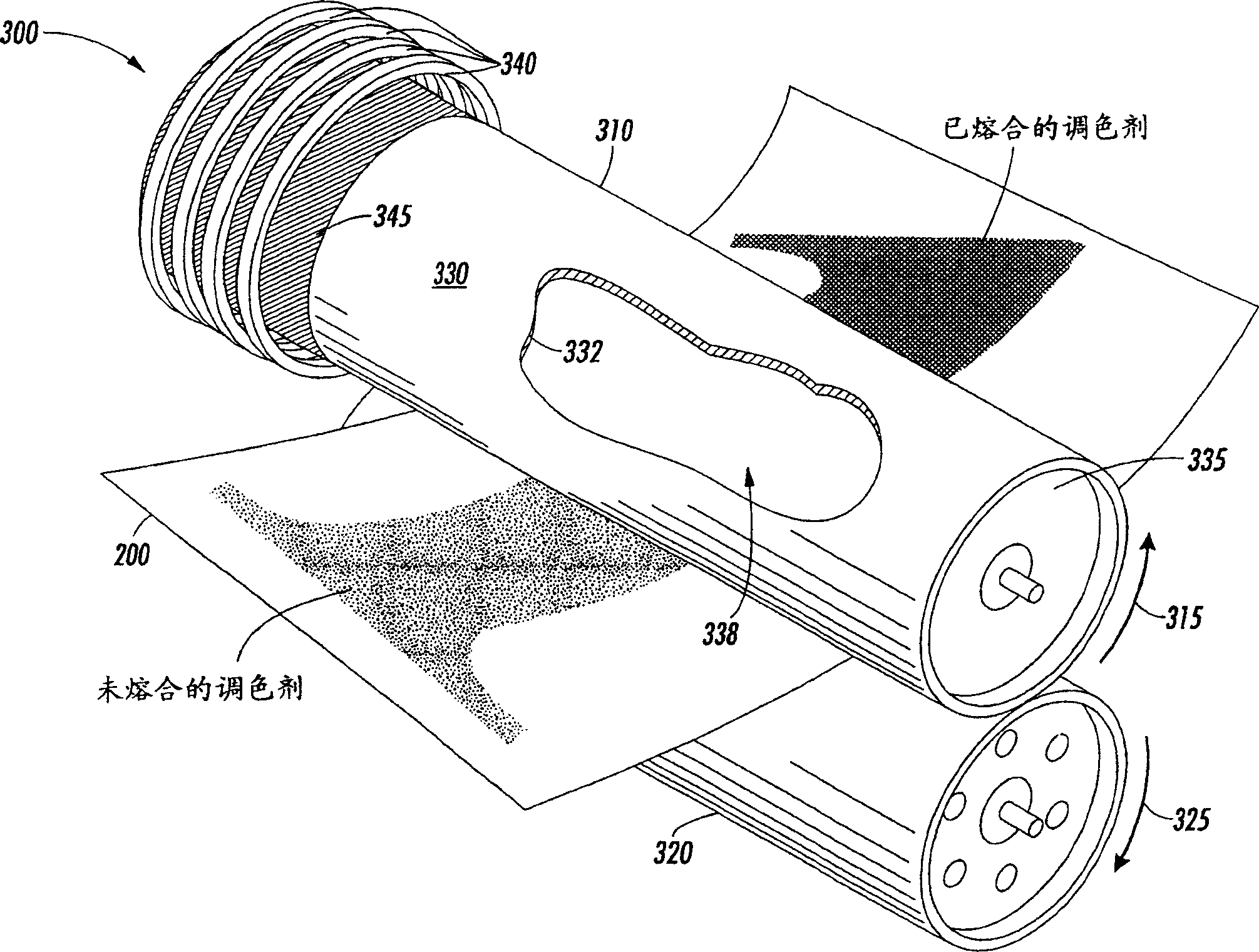

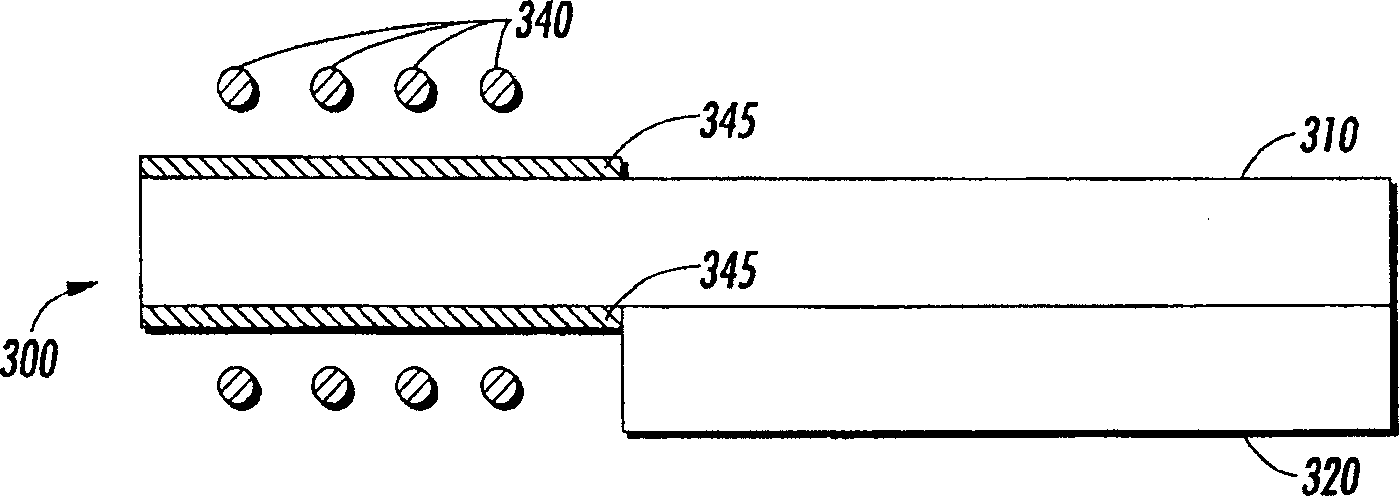

[0034] For purposes of definition and illustration, clarity and familiarity, the following description of various exemplary embodiments of the heated toner fusing system and method according to the present invention may refer to and / or illustrate one or more A specific type of heated toner fusing unit. It should be understood, however, that the principles of the invention outlined and / or discussed below are equally applicable to any known or later developed toner fusing system that utilizes heat and pressure to fuse toner particles On or in an image bearing surface of an image receiving medium, the toner particles are pre-deposited on the image bearing surface to form an image in an image forming device.

[0035] Exemplary image forming devices include, but are not limited to, printers, copiers, facsimile machines, multifunctional image making and reproducing devices, xerographic printing devices, and any other similar devices or units in which An image is formed or reproduce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com