Cellular automation method for simulating anisotropic silicon-etching process

A cellular automaton and corrosion process technology, applied in the process of producing decorative surface effects, decorative arts, gaseous chemical plating, etc., can solve the problems of complex boundary conditions, difficult to introduce high Miller index crystal planes, etc. Accurate simulation, fast simulation speed, fast and accurate simulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

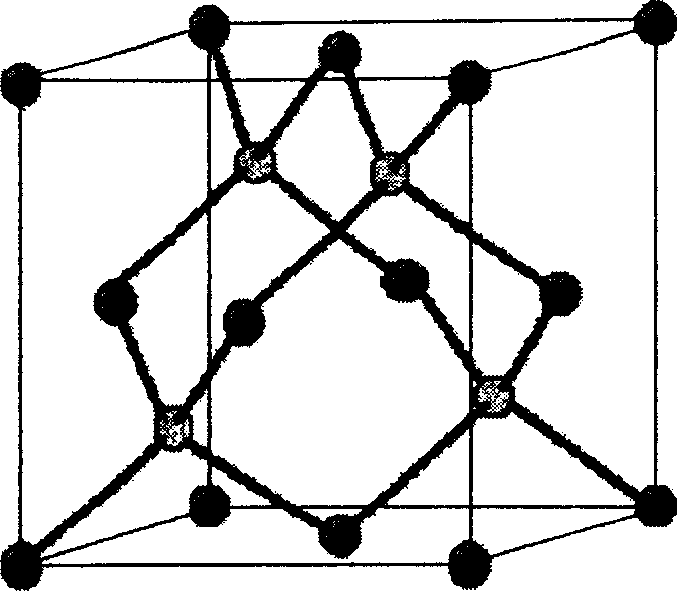

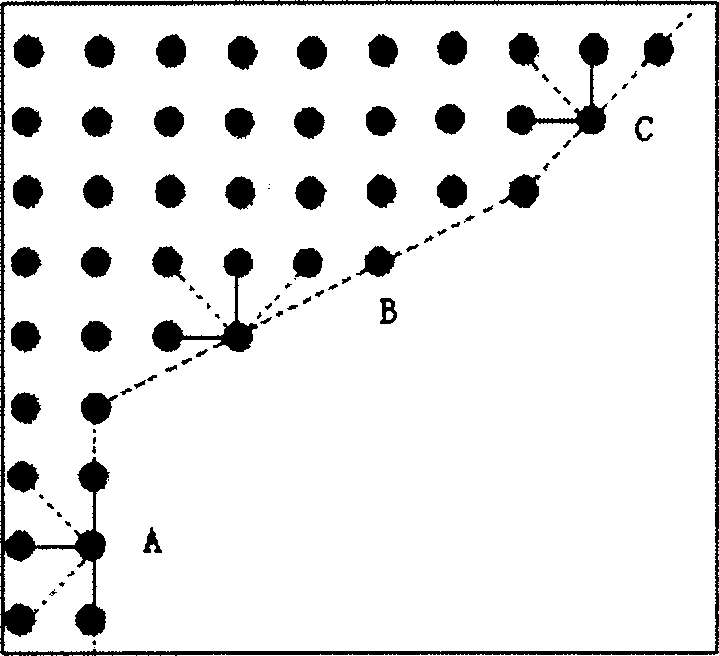

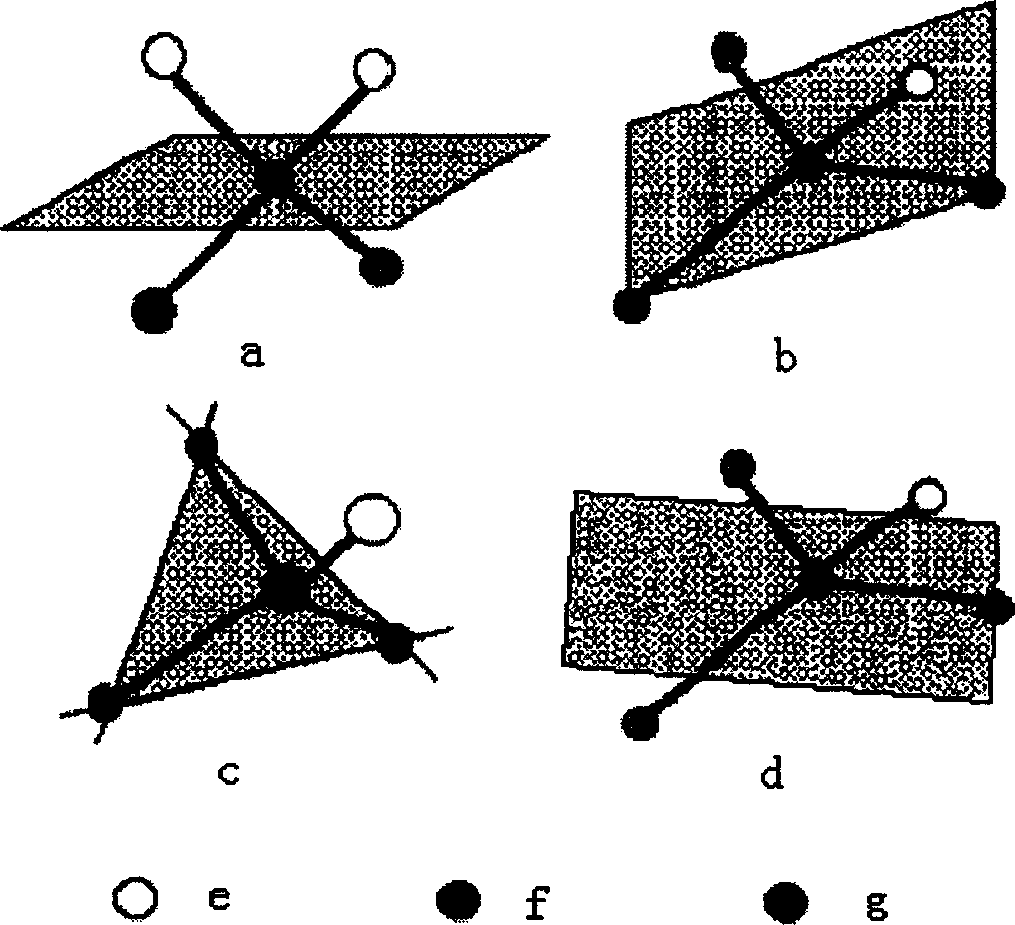

[0025] Adopt the lattice structure of disilicon in the present invention as the lattice structure of cellular automaton, as attached figure 1 shown. The crystal planes that often appear during the anisotropic etching process of more silicon are introduced into the surface layer of the substrate, and the crystal planes that appear during the cell etching process on the surface layer of the substrate affect the etching process of the internal cells of the silicon substrate. It can effectively introduce high Miller index crystal planes, and effectively simplify the boundary conditions. This method satisfies the following two conditions:

[0026] a. Using the lattice structure of silicon as the lattice structure of the cellular automaton, by introducing more crystal planes that often appear during the anisotropic etching process of silicon on the surface of the substrate, and appearing in the process of cellular etching on the surface of the substrate The crystal plane affects t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com