Method for measuring ginger utilizing 6-gingerol oxime and 6-gingerol in products thereof

A technology of gingerol oxime and gingerol, which is applied in the field of both medicine and food materials, can solve the problems of no exploration, achieve the effect of easy storage and use, and wide practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

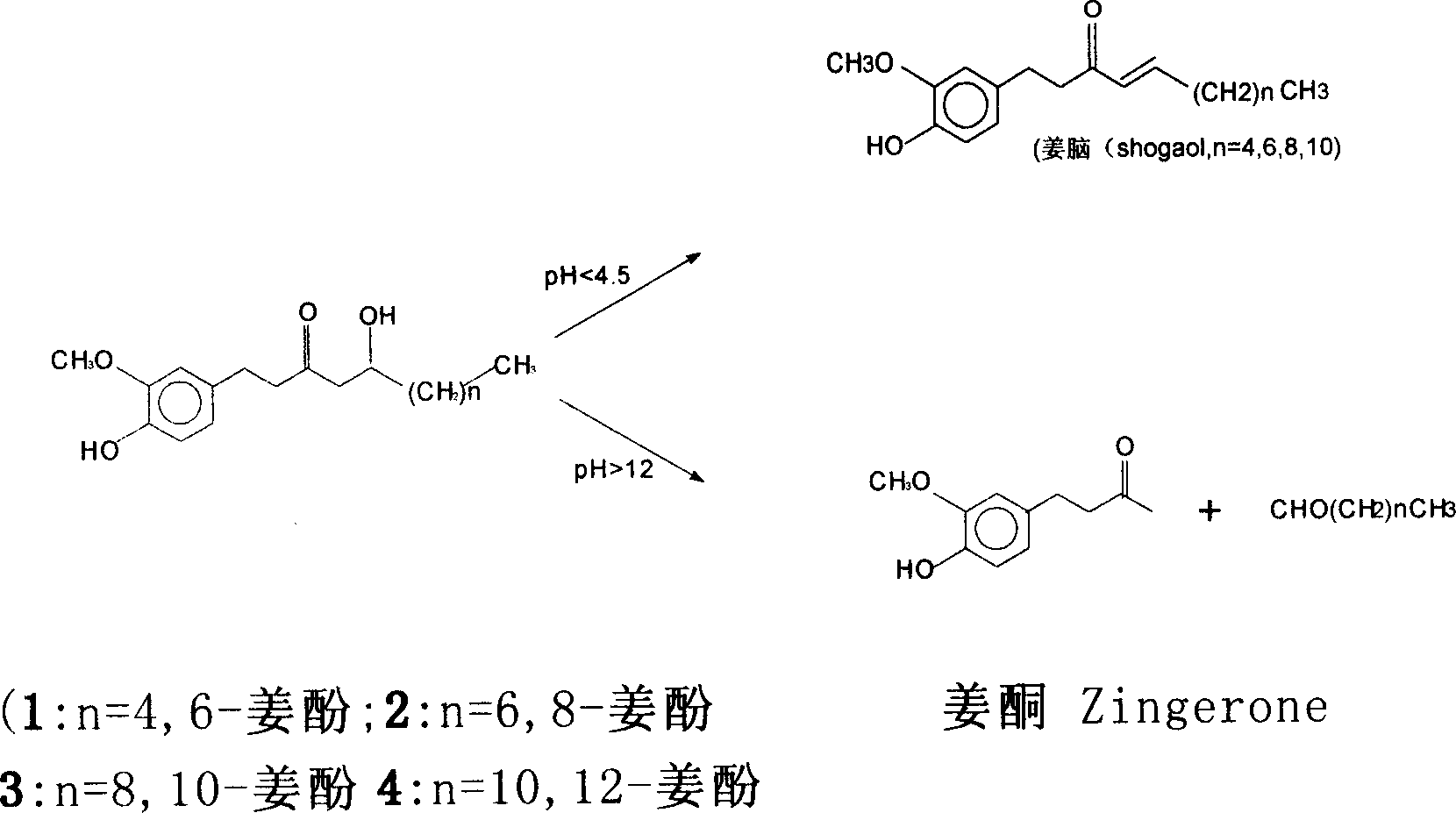

Method used

Image

Examples

Embodiment 1

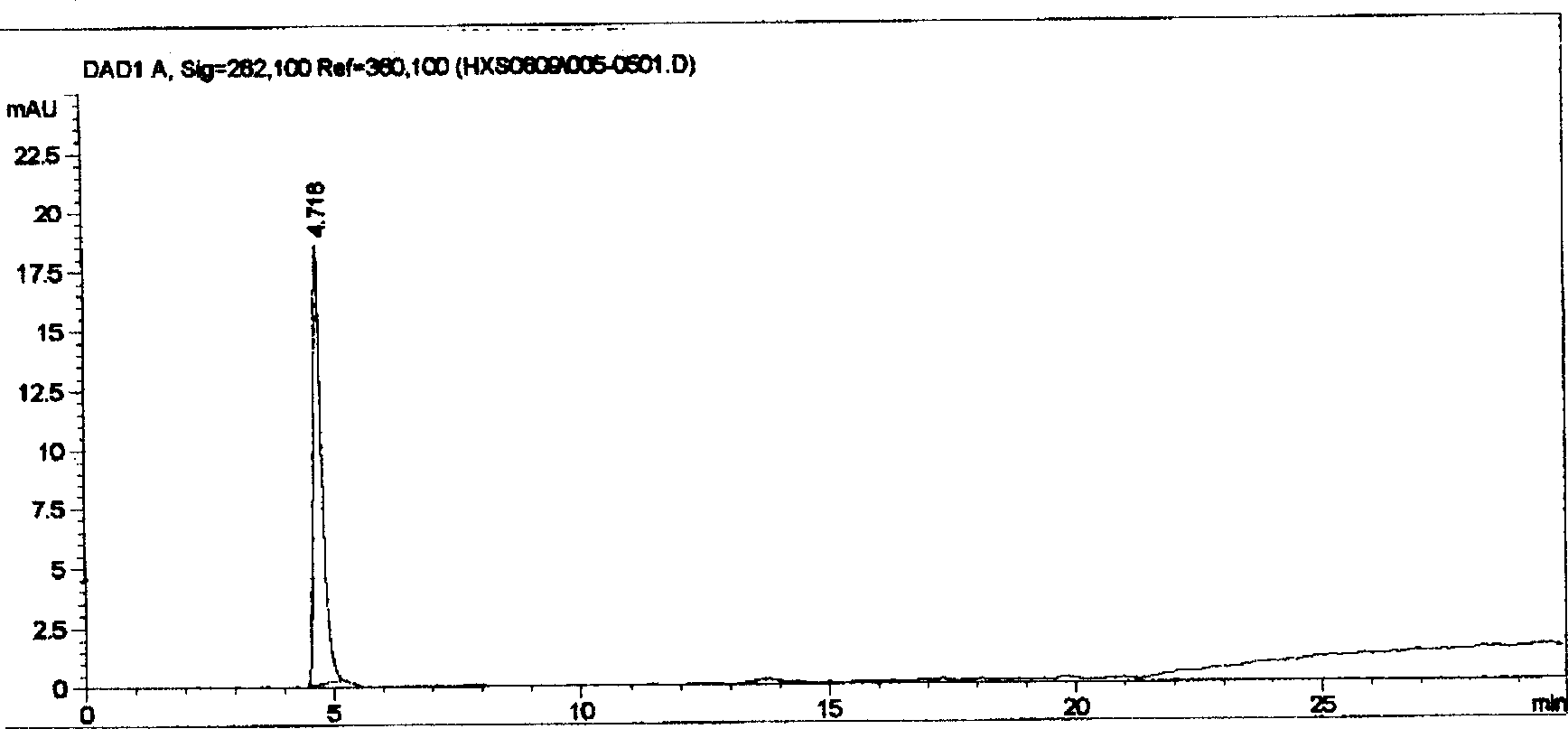

[0032] Embodiment one: the mensuration of 6-gingerol in fresh ginger

[0033] 1. Sample processing

[0034] Wash the fresh ginger, cut it into strips, and beat it in a beater. Weigh 1.000 g of ginger pulp, use 2 volumes of acetonitrile and 3 volumes of 2% acetic acid mixture, and dilute it to 10 ml to prepare a sample solution of 0.200 g of fresh ginger / ml. Put it in an ultrasonic homogenizer to oscillate and mix evenly, centrifuge at 3000 rpm, take the supernatant and filter it with a 0.22 μm nylon filter membrane. The filtrate can be used as a sample for the determination of 6-gingerol in fresh ginger. The injection volume was 2 microliters.

[0035] Add 5 μg of 6-gingerol oxime as an internal standard to the prepared samples.

[0036] 2. Conditions for determination by high pressure liquid chromatography

[0037] The injection volume at the time of measurement was 2 microliters. Mobile phase: 2 volumes of acetonitrile and 3 volumes of 2% acetic acid mixture; flow rate...

Embodiment 2

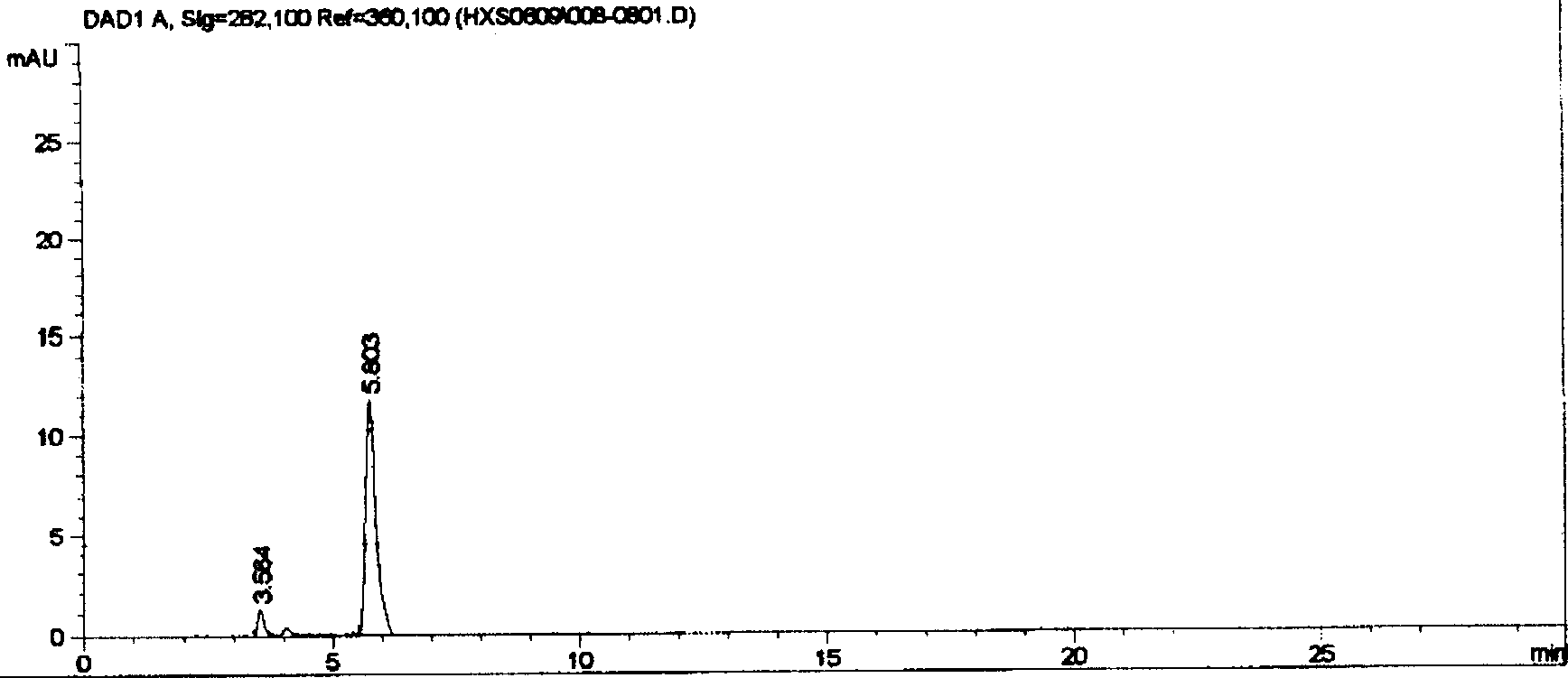

[0042] Embodiment two: the mensuration of 6-gingerol in ginger oleoresin

[0043] 1. Sample processing

[0044] Weigh 0.1000 g of ginger oleoresin, and dilute to 5 ml with 2 volumes of acetonitrile and 3 volumes of 2% acetic acid mixture to prepare a sample solution containing 0.02 g of ginger oleoresin per milliliter. Put it in an ultrasonic homogenizer to oscillate and mix well, centrifuge at 10,000 rpm, and filter the supernatant with a 0.22 μm nylon filter membrane. The filtrate can be used as a sample for the determination of 6-gingerol in fresh ginger.

[0045] 2, the condition that high-pressure liquid chromatograph measures: with embodiment one.

[0046] 3, The qualitative of 6-gingerol: with embodiment one.

[0047] 4. Calculation of 6-gingerol content in ginger and its products

[0048] The content of 6-gingerol calculated according to ① formula is: 4.01±0.18% (n=3).

Embodiment 3

[0049] The mensuration of 6-gingerol in the dried ginger of embodiment three

[0050] 1. Sample processing

[0051] Weigh 1.000 g of dried ginger, use 10 ml of a mixture of 2 volumes of acetonitrile and 3 volumes of 2% acetic acid, shake and mix in an ultrasonic homogenizer, centrifuge at 3000-10000 speed, take the supernatant and filter it with 0.22 μm nylon Membrane filtration. Use 2 volumes of acetonitrile and 3 volumes of 2% acetic acid to dilute to 100 ml. Add 500 µg of 6-gingerol oxime as an internal standard to the prepared samples.

[0052] 2, the condition that high-pressure liquid chromatograph measures: with embodiment one.

[0053] 3, The qualitative of 6-gingerol: with embodiment one.

[0054] 4. Calculation of 6-gingerol content in ginger and its products:

[0055] The content of 6-gingerol calculated according to the formula ① is: 0.22±0.016% (n=3).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com