Method for determining styrene micro-emulsion polymerization conversion rate by ultraviolet spectrometry

A technology of microemulsion polymerization and ultraviolet spectroscopy, which is applied in the field of determining the conversion rate of styrene microemulsion polymerization, can solve the problems of poor accuracy, loss of polymerization products, and difficulty in accurately measuring the conversion rate of styrene, achieving high accuracy, easy operation, The effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

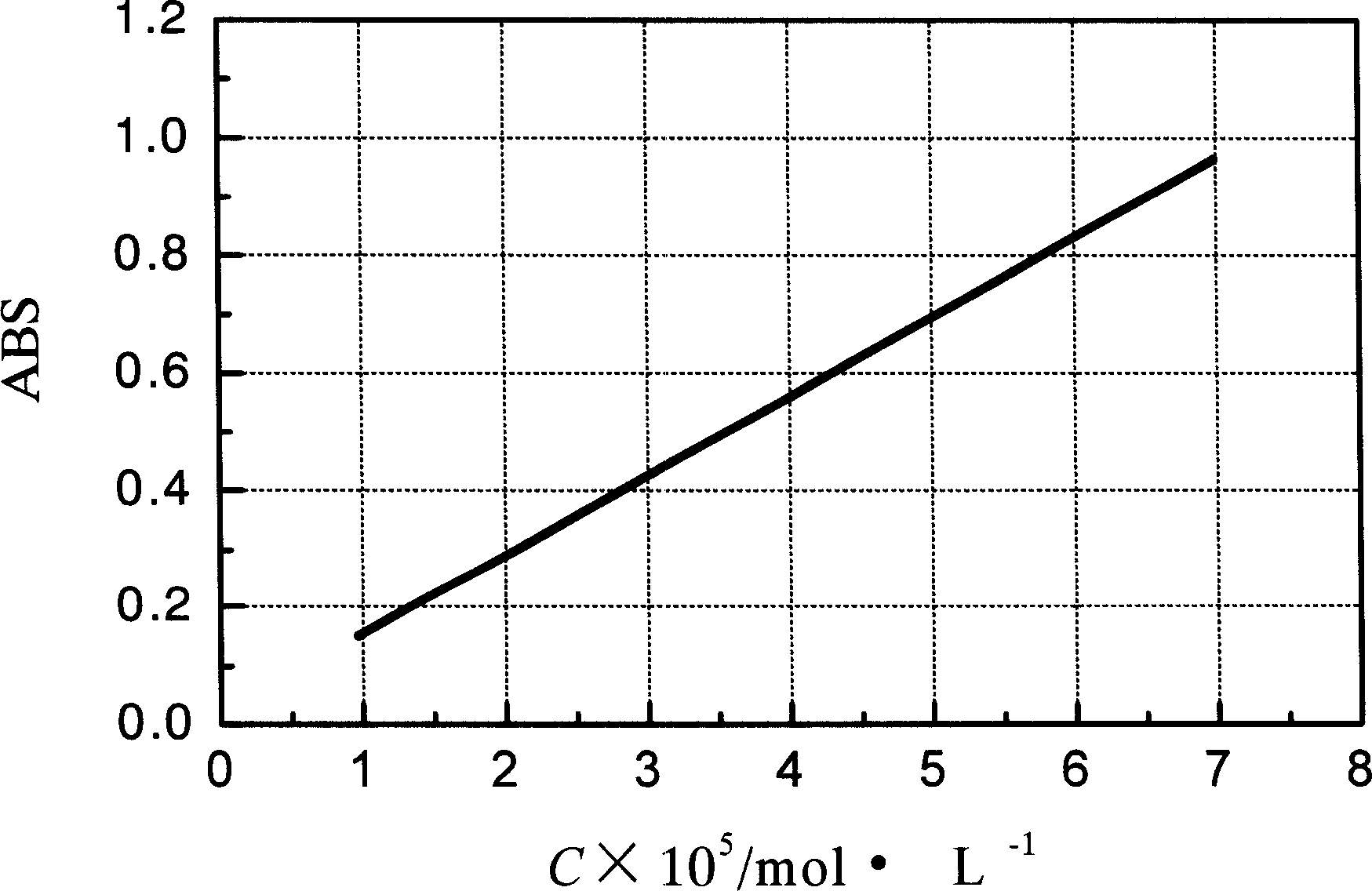

[0014] A system consisting of 3.8ml styrene, 3.4ml n-pentanol, 3.5gSDS, and 70.0ml water was reacted for 90 minutes at an ultrasonic frequency of 19.6kHz, a power of 180W, and 30°C. 1ml was sampled, and 100ml of 95% ethanol was added to precipitate and separate Polymer, then take 1ml of the supernatant, dilute 50 times with 95% ethanol, and measure the absorbance of the diluted sample at 247nm as 0.5640 with a UV spectrophotometer. Find that the concentration of styrene in this diluted sample is 3.94 * 10 by accompanying drawing (Fig. 1). -5 mol L -1 , that is, the concentration of styrene in the reaction system is 0.197mol L -1 According to the above formula, the conversion rate of styrene can be obtained to be 53.7%.

Embodiment 2

[0016] A system consisting of 4.0ml styrene, 3.5ml n-pentanol, 4.0gSDS, and 72.5ml water was reacted for 60 minutes at an ultrasonic frequency of 19.6kHz, a power of 180W, and 40°C. 1ml was sampled, and 100ml of 95% ethanol was added to precipitate and separate Polymer, then take 1ml of the supernatant, dilute 50 times with 95% ethanol, and measure the absorbance of the diluted sample at 247nm as 0.4629 with a UV spectrophotometer. Find that the concentration of styrene in this diluted sample is 3.25 * 10 by accompanying drawing (Fig. 1). -5 mol L -1 , that is, the concentration of styrene in the reaction system is 0.163mol L -1 According to the above formula, the conversion rate of styrene can be obtained as 62.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com