Production of superfine cobalt powder by air-flow breaking process

A technology of jet milling and ultrafine cobalt powder, which is applied in the field of jet milling to produce ultrafine cobalt powder, which can solve the problems of increasing oxygen content, cobalt powder surface oxidation, and affecting the performance of cobalt powder, so as to improve dispersion and hard alloy Improved performance and higher specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

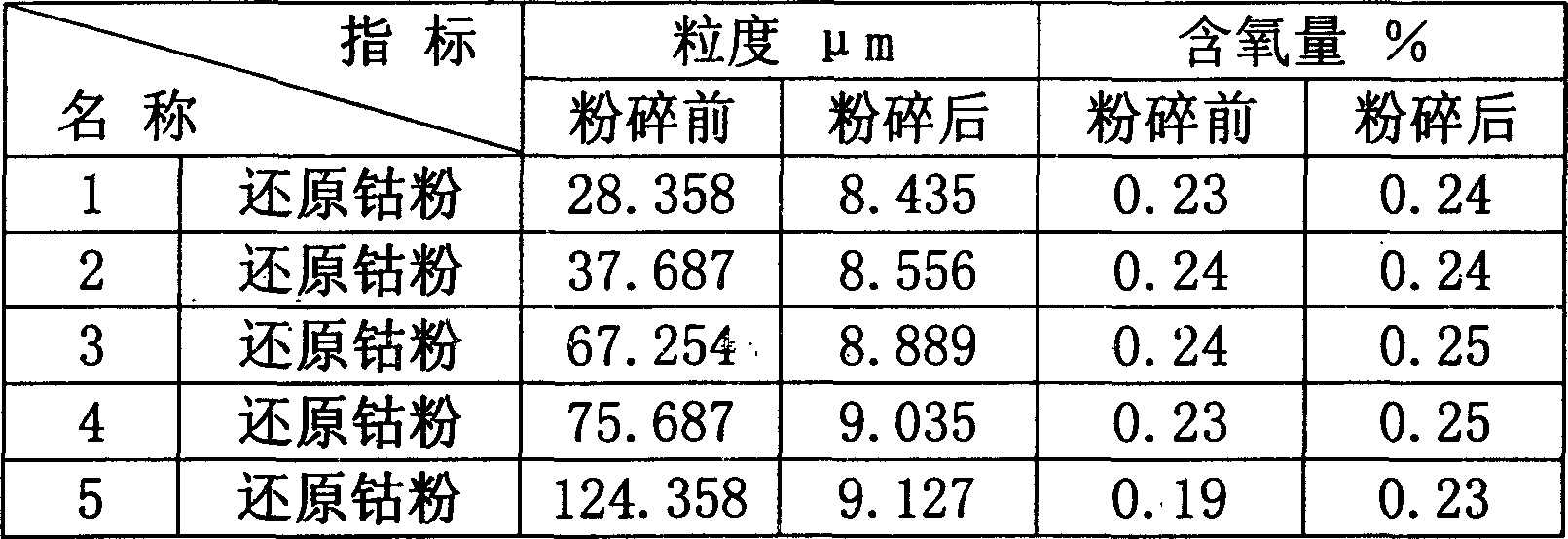

[0013] The cobalt powder reduced by cobalt oxalate was used as the protective atmosphere with nitrogen, and the crushing pressure was controlled at 0.6MPa. The results before and after crushing are shown in Table 1:

[0014] Table 1-Comparison of results before and after cobalt powder pulverization

[0015]

[0016] It can be seen from Table 1 that after pulverization of cobalt powder with a particle size between 20 μm and 130 μm, the particle size and oxygen content can meet the requirements, and the maximum oxygen content increases by 400 ppm.

Embodiment 2

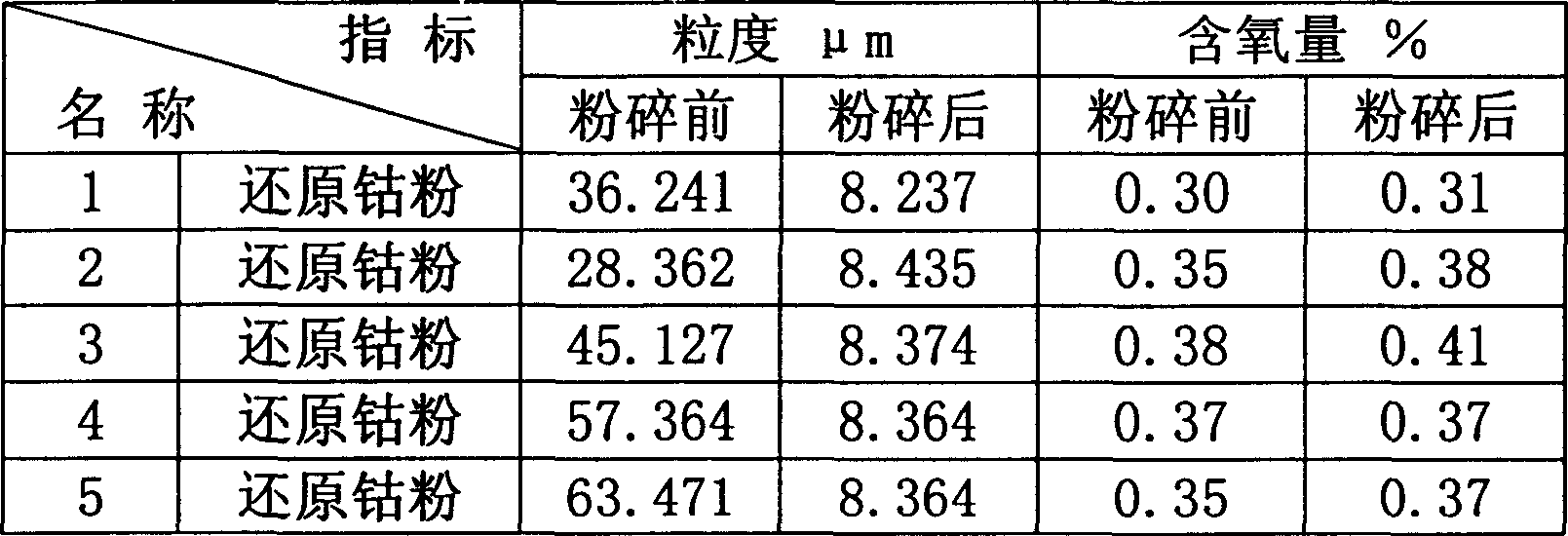

[0018] The cobalt powder reduced by cobalt oxalate was used as the protective atmosphere with nitrogen, and the crushing pressure was controlled at 0.45MPa. The results before and after crushing are shown in Table 2:

[0019] Table 2-Comparison of results before and after cobalt powder pulverization

[0020]

[0021] It can be seen from Table 2 that after cobalt powder with a particle size between 25 μm and 65 μm is pulverized, the particle size and oxygen content can meet the requirements, and the maximum oxygen content increases by 400 ppm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com