Dry cleaner for car body and production thereof

A technology for dry cleaning agent and car body, which is applied in the field of composite car body dry cleaning agent and its preparation, can solve the problems that waxing and polishing can only be carried out separately, cannot be completed at one time, environmental pollution, etc., so as to alleviate the shortage of water resources and save energy. Labor cost and effect of saving water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The product formula is:

[0036] Diethanolamine: 1.5%

[0037] Sulfonic acid: 2.5%

[0038] Synthetic wax: 20%

[0039] Diatomaceous earth: 1.5%

[0040] Water: 74.5%

[0041] Preparation:

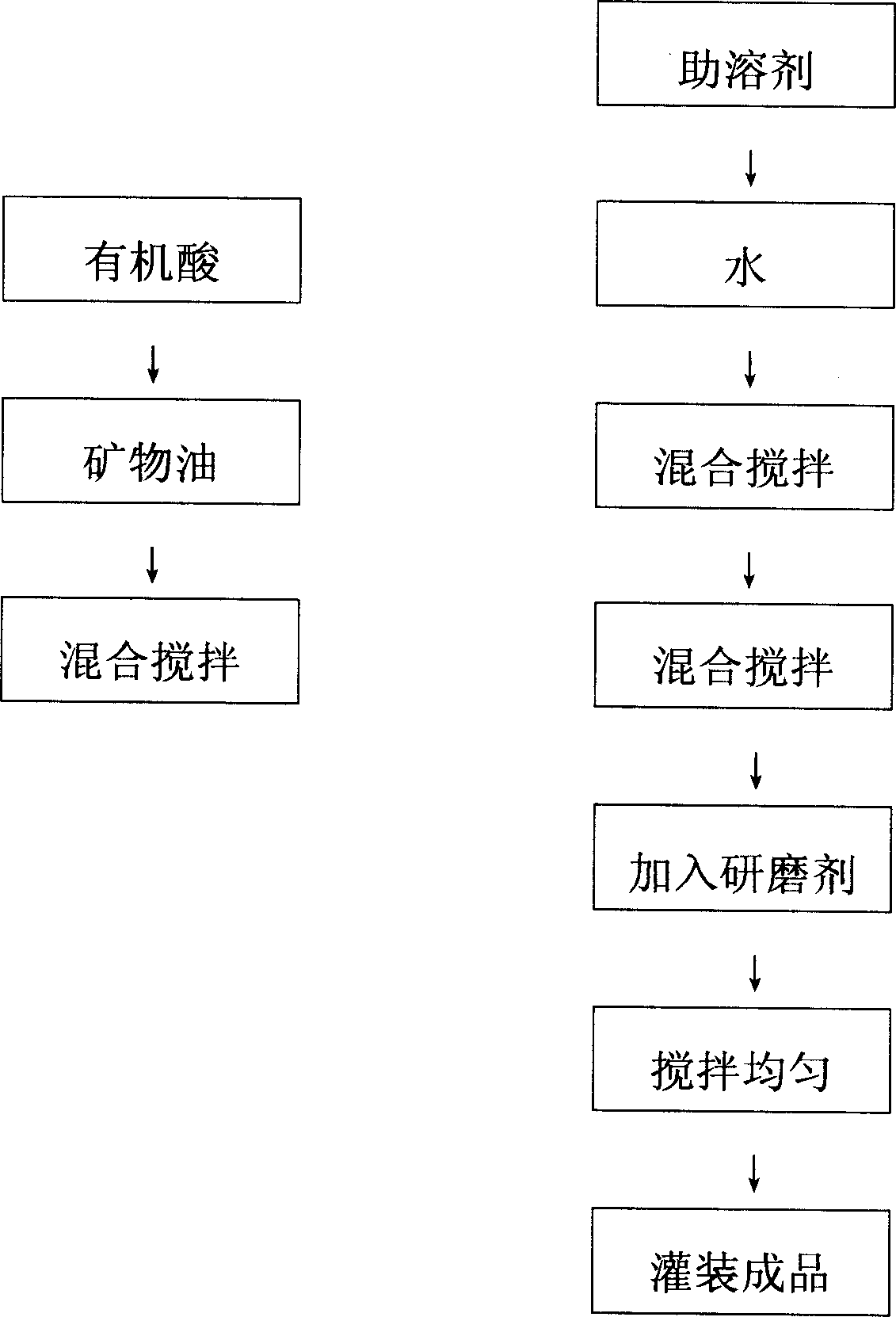

[0042] Such as figure 1 1.5 kg of organic solvent diethanolamine is dissolved in 74.5 kg of water, and at the same time, 2.5 kg of organic acid sulfonic acid and 20 kg of synthetic wax are mixed evenly, and the mixed organic acid sulfonic acid and synthetic wax are added to the water dissolved in organic solvent diethanolamine , stir evenly, add 1.5 kg of abrasive diatomite, stir evenly, measure and fill the product.

Embodiment 2

[0044] The product formula is:

[0045] Ethanol: 2.5%

[0046] Maleic acid: 3%

[0047] Paraffin: 30%

[0048] Diatomaceous earth: 2%

[0049] Water: 62.5%

[0050] Preparation:

[0051] Such as figure 1 2.5 kilograms of organic solvent ethanol are dissolved in 62.5 kilograms of water, and 3 kilograms of organic acid maleic acid and 30 kilograms of paraffin are mixed uniformly simultaneously, and the mixed maleic acid and paraffin are added into the water that is dissolved with organic solvent ethanol, stir well, Add 2 kg of abrasive diatomaceous earth, stir evenly, measure and fill the product.

Embodiment 3

[0053] The product formula is:

[0055] EDTA: 1.5%

[0056] Beeswax Oil: 10%

[0057] Diatomaceous earth: 0.5%

[0058] Water: 87.5%

[0059] Preparation:

[0060] Such as figure 1 1. Dissolve 0.5 kg of petroleum ether as an organic solvent in 87.5 kg of water, mix 1.5 kg of organic acid EDTA and 10 kg of beeswax oil evenly, add the mixed EDTA and beeswax oil into the water dissolved in petroleum ether as an organic solvent, and stir evenly , add 0.5 kg of abrasive diatomaceous earth, stir evenly, measure and fill the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com