Steel-liquid with vanadium and nitrogen alloying composite wire

A technology of nitrogen alloying and cored wire, applied in the field of cored wire, can solve the problems of low recovery rate, vanadium loss, lack of ductility, etc., and achieve the effect of convenient application and improved recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

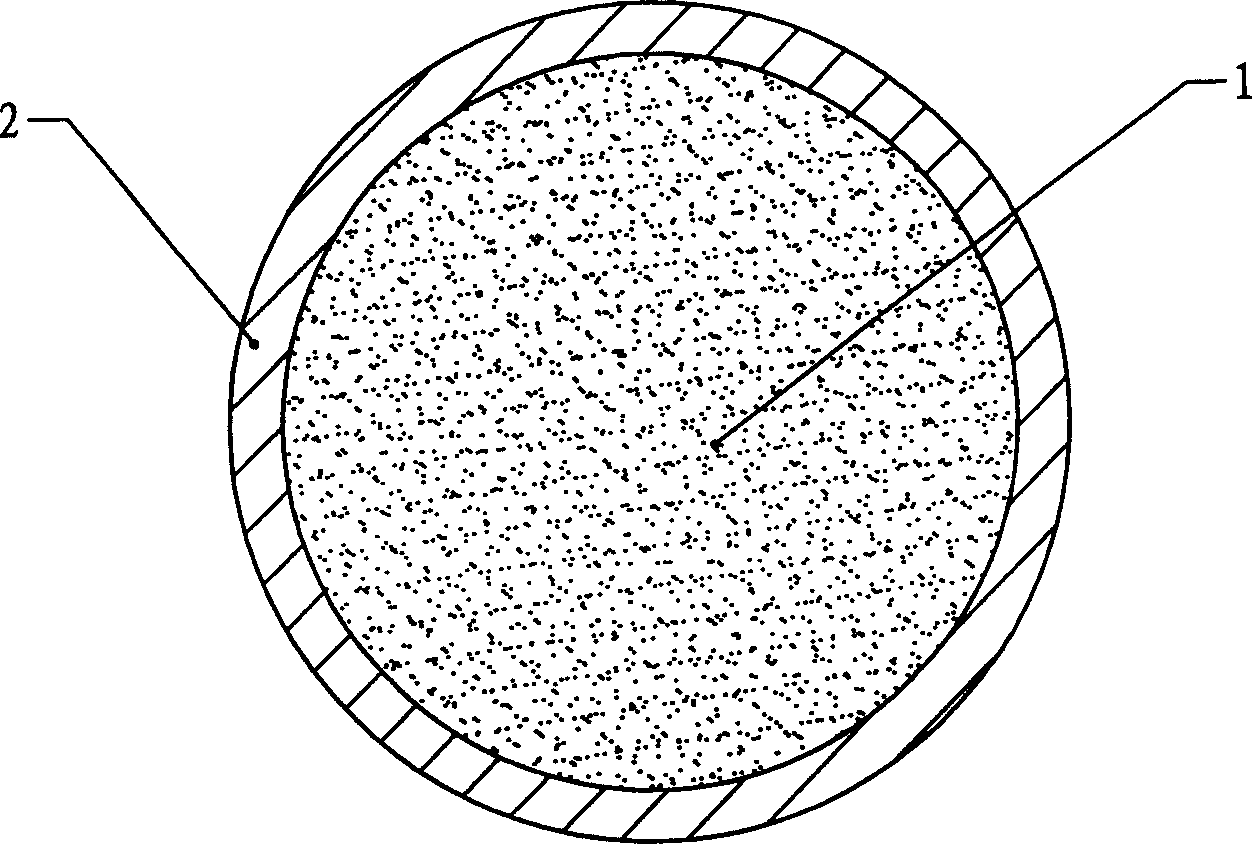

[0014] Embodiment 1: VN12 vanadium nitride alloy is selected, the chemical composition of VN12 vanadium nitride alloy is V 79.0%, N 11.5% by weight percentage, and the rest are impurity elements. The VN12 vanadium nitride alloy is crushed into 0-3mm powder with a crusher, and the chemical composition of the prepared powder is V 80.0%, N 11.5% by weight, and the rest is Fe and impurity elements. The ST12 cold-rolled steel strip with a thickness of 0.35mm is used as the outer layer 2, and the above powder is wrapped as the core layer 1 on the core wrapping equipment to make a cored wire with an outer diameter of 12mm. The weight per meter of the finished cored wire is 360-380g, of which the weight of the steel tare is 120g, and the weight of the powder is 240-260g.

[0015] In the 125 tons of molten steel after refining in the ladle refining furnace, 800 meters of the above-mentioned cored wire containing VN12 vanadium nitride alloy is fed into the depth of the molten steel by u...

Embodiment 2

[0016] Embodiment 2: press VN12 vanadium nitride alloy: the ratio of Ti30A titanium alloy=3.33:1, choose VN12 vanadium nitride alloy and Ti30A alloy respectively, wherein the chemical composition of VN12 vanadium nitride alloy is V 78.5%, N 11.6%, and the rest are impurity elements. The chemical composition of Ti30A titanium alloy is 29.5% by weight, and the rest are Fe and impurity elements. The alloy of the above ratio is crushed into 0-3mm powder with a crusher, and physically mixed with a mixer. The chemical composition of the prepared powder is 60.4% by weight, N8.9%, Ti 6.8%, and the rest is Fe and impurity elements. The ST12 cold-rolled steel strip with a thickness of 0.4mm is used as the outer layer 2, and the above-mentioned powder is wrapped as the core layer 1 on the core wrapping equipment to make a cored wire with an outer diameter of 14mm. The weight of the finished cored wire per meter is 500-520g, of which the weight of the steel tare is 160g, and the weight o...

Embodiment 3

[0018] Embodiment 3: select alloy respectively by the ratio of VN12 vanadium nitride alloy: Ti30A titanium alloy: Nb60 niobium alloy=3.33: 1: 1, wherein the chemical composition of VN12 vanadium nitride alloy is V 79.5%, N 11.5% by weight percentage , and the rest are impurity elements. The chemical composition of Ti30A titanium alloy is Ti 29.0% by weight, and the rest are Fe and impurity elements. The chemical composition of Nb60 niobium alloy is Nb59.4% by weight, and the rest are Fe and impurity elements. The alloy of the above ratio is crushed into 0-3mm powder with a crusher, and physically mixed with a mixer. The chemical composition of the prepared powder is V 49.7%, N 7.2%, Ti5.4%, Nb11.1 %, the rest are Fe and impurity elements. The ST12 cold-rolled steel strip with a thickness of 0.35mm is used as the outer layer 2, and the above powder is wrapped as the core layer 1 on the core wrapping equipment to make a cored wire with an outer diameter of 14mm. The weight of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com