Waste water treating process of circulation sequence batched active sludge and its active sludge reactor

A technology of activated sludge method and sewage treatment, applied in water/sludge/sewage treatment, biological water/sewage treatment, sustainable biological treatment, etc. Continuous effluent and other problems, to achieve the effect of improving equipment utilization, ensuring effluent quality, and overcoming uneven sludge concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

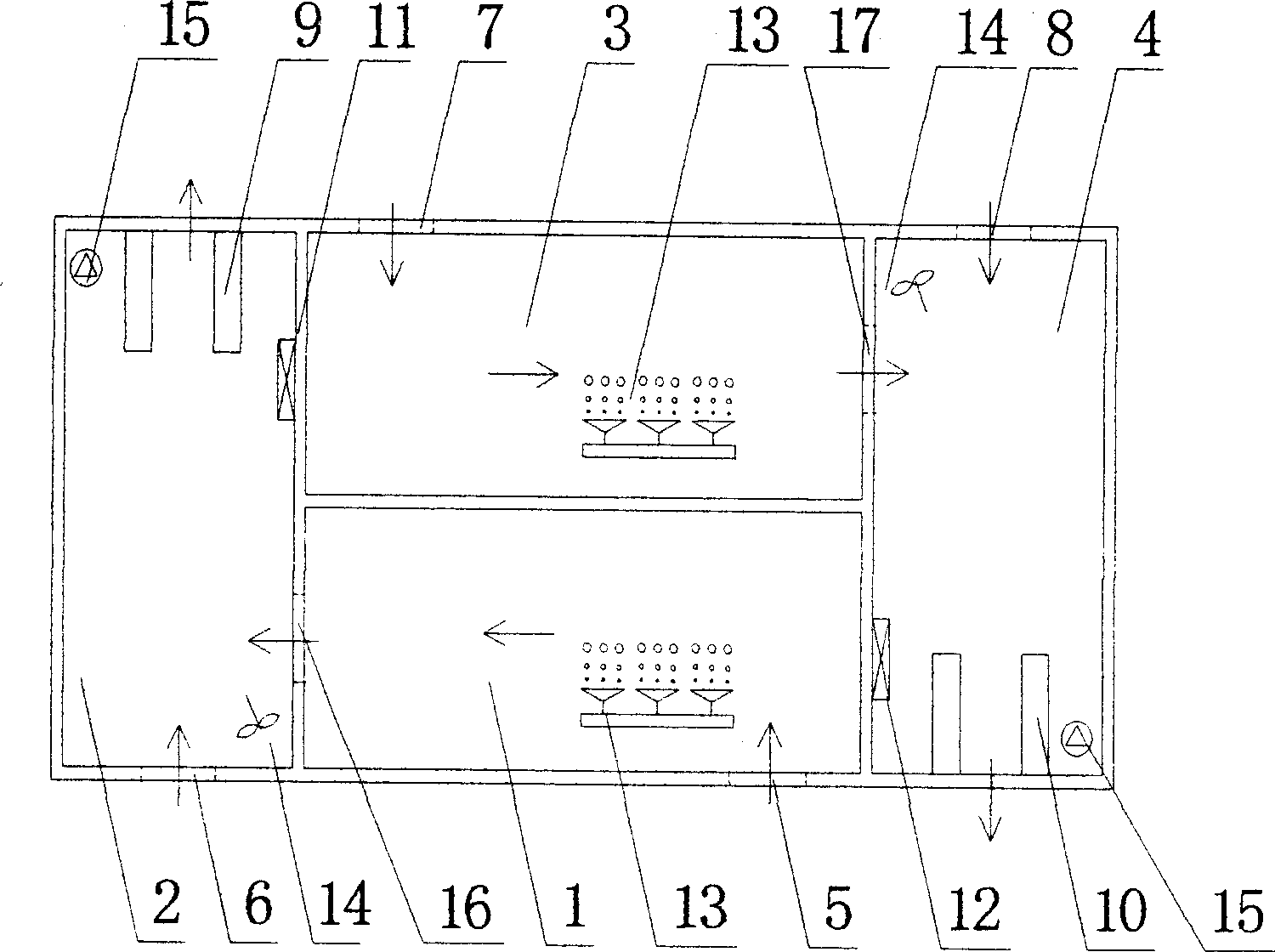

[0034] Below in conjunction with accompanying drawing and specific embodiment, further detailed description is made to the cyclic sequence batch type activated sludge method sewage treatment process and its activated sludge reactor of the present invention:

[0035] The circulating sequencing batch activated sludge reactor of the present invention shown in the figure has four sewage reaction tanks with rectangular structures. The four rectangular sewage reaction pools are divided into the first main reaction pool 1, the first auxiliary reaction pool 2, the second main reaction pool 3 and the second auxiliary reaction pool 4, wherein: the first and second main reaction pools 1 and 3 The size parameters are the same, they are arranged side by side, and share a pool wall in the middle; the size parameters of the first and second auxiliary reaction pools 2, 4 are the same, and they are respectively arranged in the first and second main reaction pools 1, 3 Both sides, and one of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com