Motor vehicle coolant circuit comprising a pump and a retarder

A coolant circuit and reducer technology, which is applied in engine cooling, liquid cooling, coolant flow control, etc., can solve problems such as increasing fuel consumption, increasing weight, and increasing power consumption of coolant pumps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

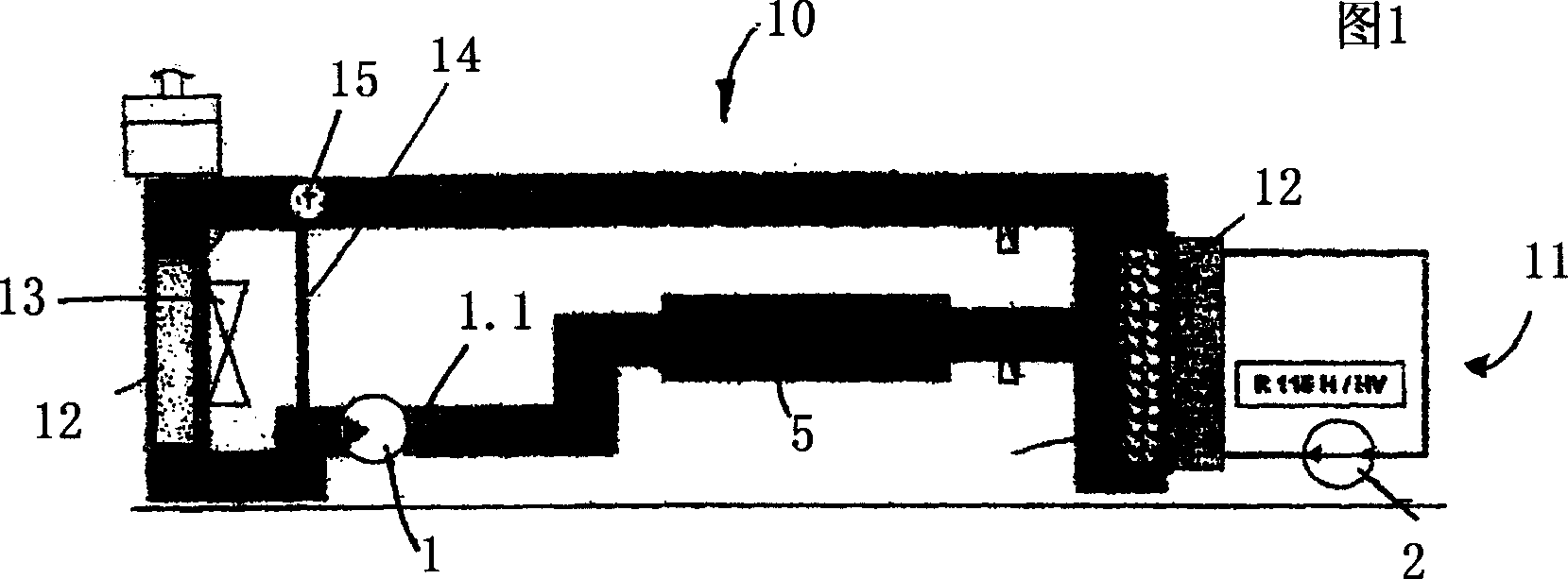

[0020] A coolant circuit 10 and a gear unit operating medium circuit 11 can be seen in FIG. 1 . According to the prior art, the two circuits are implemented separately. The coolant circulates in the coolant circuit 10 by means of the coolant pump 1 , and the working medium in the gear reducer working medium circuit 11 circulates by means of the gear reducer 2 . The two circuits are connected to each other by means of an oil-water heat exchanger 12 so that the heat generated in the gear unit 2 can be transferred into the coolant circuit 10 . Conventionally, heat is dissipated from the coolant circuit 10 by means of a radiator 12 and a blower wheel rotor 13 . As long as it is not necessary to dissipate heat energy from the coolant circuit 10 for reasons of the coolant temperature, the coolant bypasses the radiator via the bypass 14 . A thermostat 15 is provided for proper adjustment.

[0021] The cooling fluid flow required for energy transfer, especially the cooling water fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com