Bend forming process for bamboo products and forming die thereof

A technology of bending forming and processing method, which is applied in the field of bending forming processing of bamboo products and forming molds, can solve problems such as difficult to guarantee the quality and aesthetics of bamboo products, not suitable for production requirements, high labor intensity, etc., and achieve easy processing and complex Directional bending processing, high labor productivity, and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

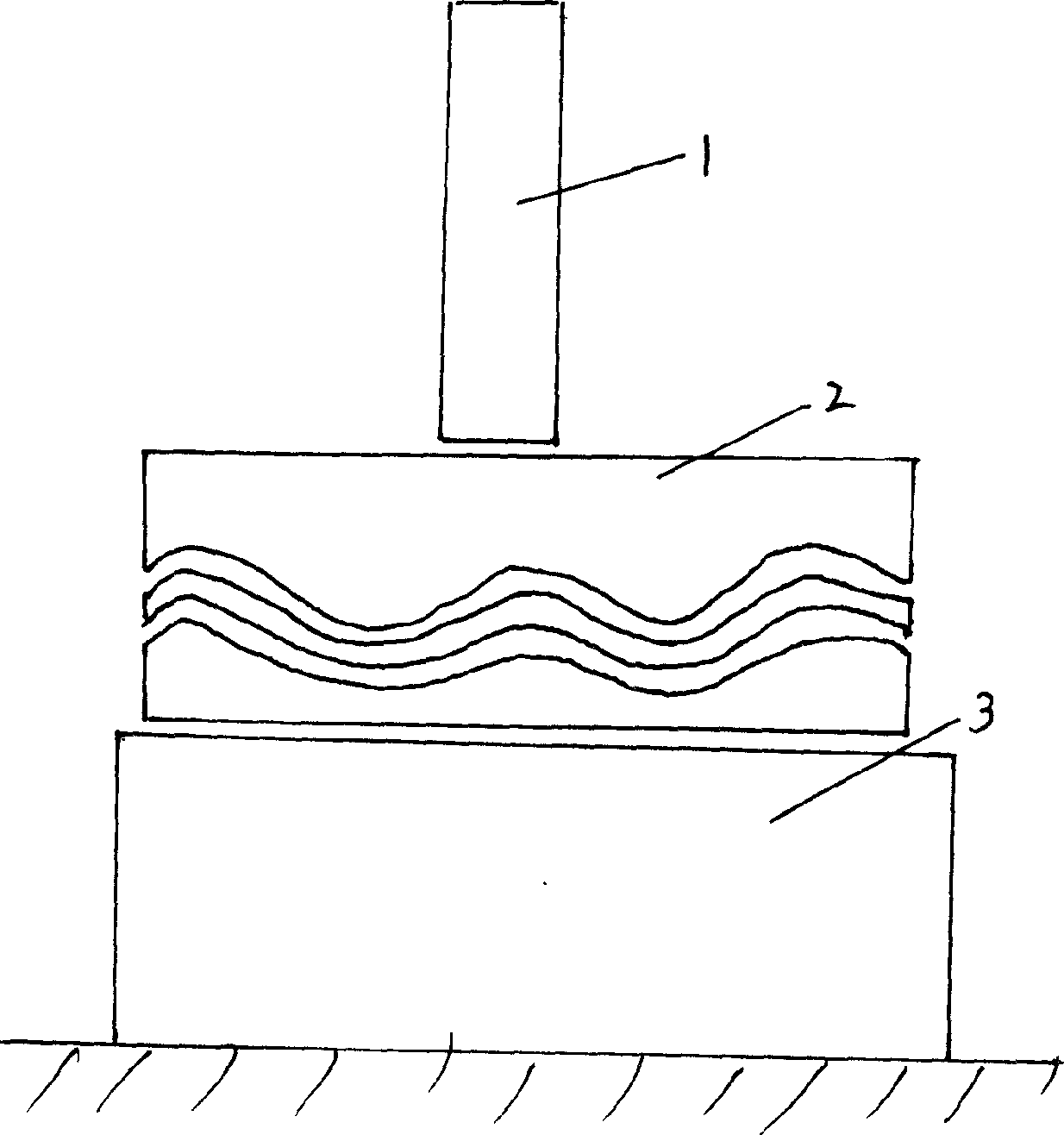

[0021] Example 1, cut a piece of raw bamboo into a rod-shaped body of a certain thickness, after rough machining and trimming, put it in a steam box, and after continuing for 20 minutes in a temperature environment of 90°C, take it out and put it in the figure 1 Shown, in the molding die that is made up of upper module 2 and lower module 3 that can be put into press 1, offer at least one molding groove that can put original bamboo between upper and lower module 2,3, by press machine The upper and lower molds are fixed up and down, so that the raw bamboo is shaped in the molding mould, and then the shaped raw bamboo is taken out and put into an oven for drying. The drying temperature in the oven is 45°C until the formed raw bamboo When the water content is 9%, it becomes a shaped bamboo product. The described drying and shaping can also put the shaped original bamboo into an oven together with the mould, and carry out drying and shaping processing.

Embodiment 2

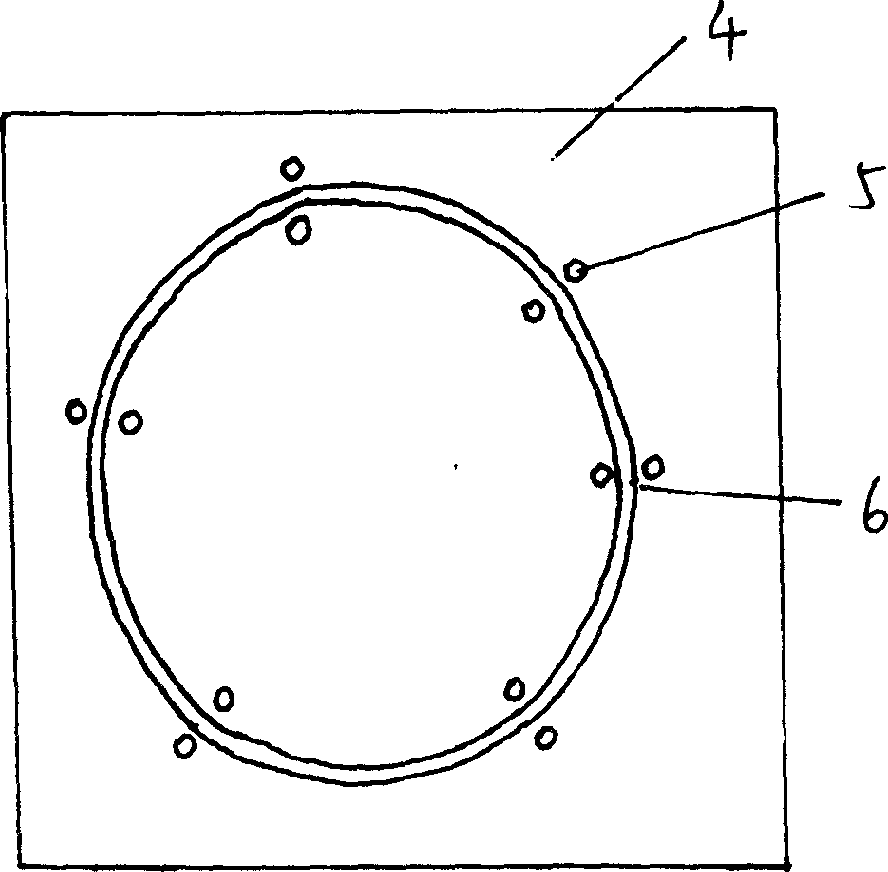

[0022] Example 2, a piece of bamboo is roughly processed and trimmed, then put into a large pot with 95°C boiling water and boiled for 30 minutes, after taking it out, put it in such as figure 2 In the shown special-purpose molding die, the composition of this molding die is: a flat end surface of a module 4 is provided with a plurality of positioning protrusions 5 arranged according to a certain circular track, which can be clamped into softened bamboo chips. Bending and forming clamping slot 6; the positioning column 5 on the bending forming clamping slot 6 is formed by two adjacent fixed positioning columns, and softened bamboo pieces are sandwiched between the two adjacent positioning columns 5 to make it shape. The positioning column 5 is made of iron pipe, which is movably plugged into a flat end surface of the module 4 or fixed by welding. The formed bamboo chips are taken out and put into an oven for drying. The drying temperature in the oven is 65° C. until the moist...

Embodiment 3

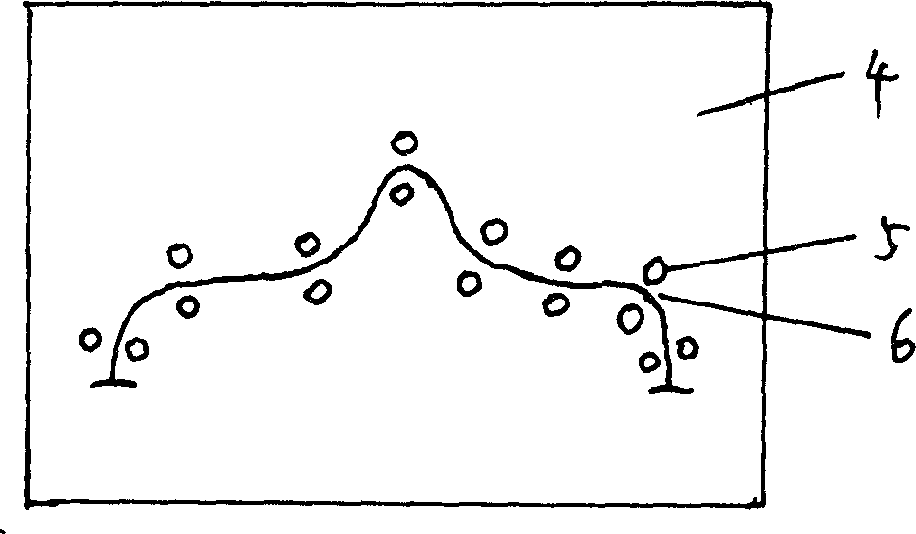

[0023] Example 3, a bamboo strip is roughly processed and trimmed, then put into a large pot with 99°C boiling water and boiled for 40 minutes, after taking it out, put it in such as image 3 In the special forming mold for clothes hanger shown, the composition of the forming mold is the same as figure 2 Shown is the same, it is also set on a flat end face of a module 4 by a plurality of arranged by a certain hanger body trajectory, can be clamped into the bending forming clamping groove 6 that the positioning boss 5 of softening bamboo strip constitutes; The positioning column 5 on the bending forming clamping groove 6 is formed by two adjacent fixed placements, and softening bamboo strips are clamped between two adjacent positioning columns 5 to make it shape. The positioning column 5 is made of iron pipe, which is movably plugged into a flat end surface of the module 4 . Put the molded bamboo strips together with the mold into an oven for drying. The drying temperature in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com