Perovskites semimetal composite multilayer membrane prepared by one ingredient and use thereof

A composite multilayer film and perovskite technology, which is applied in the direction of metal layered products, layered products, chemical instruments and methods, etc., can solve the problems of unfavorable device applications, low tunneling magnetoresistance ratio, etc., and achieve good crystal Grid matching, high tunneling magnetoresistance ratio, and improved device performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~12

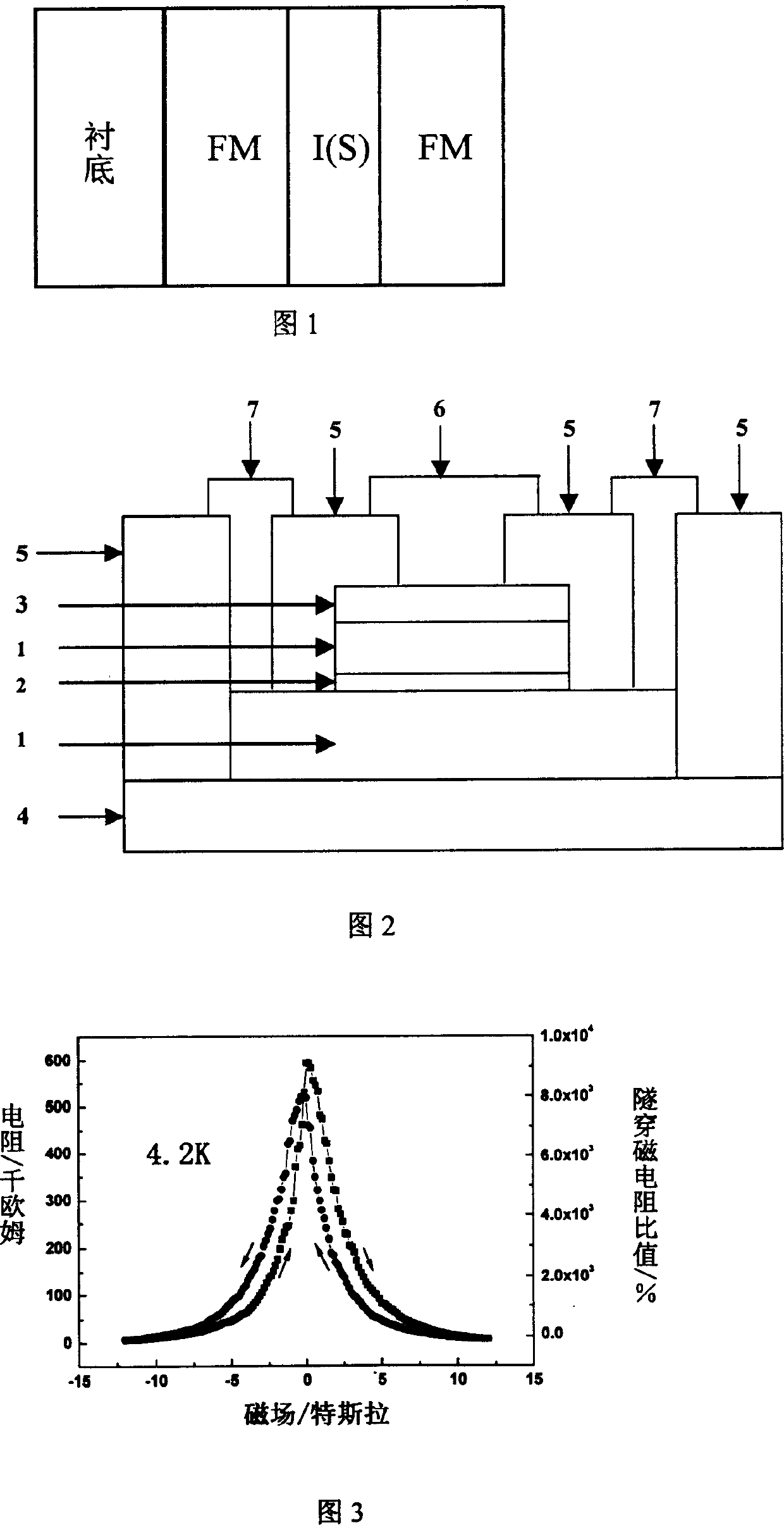

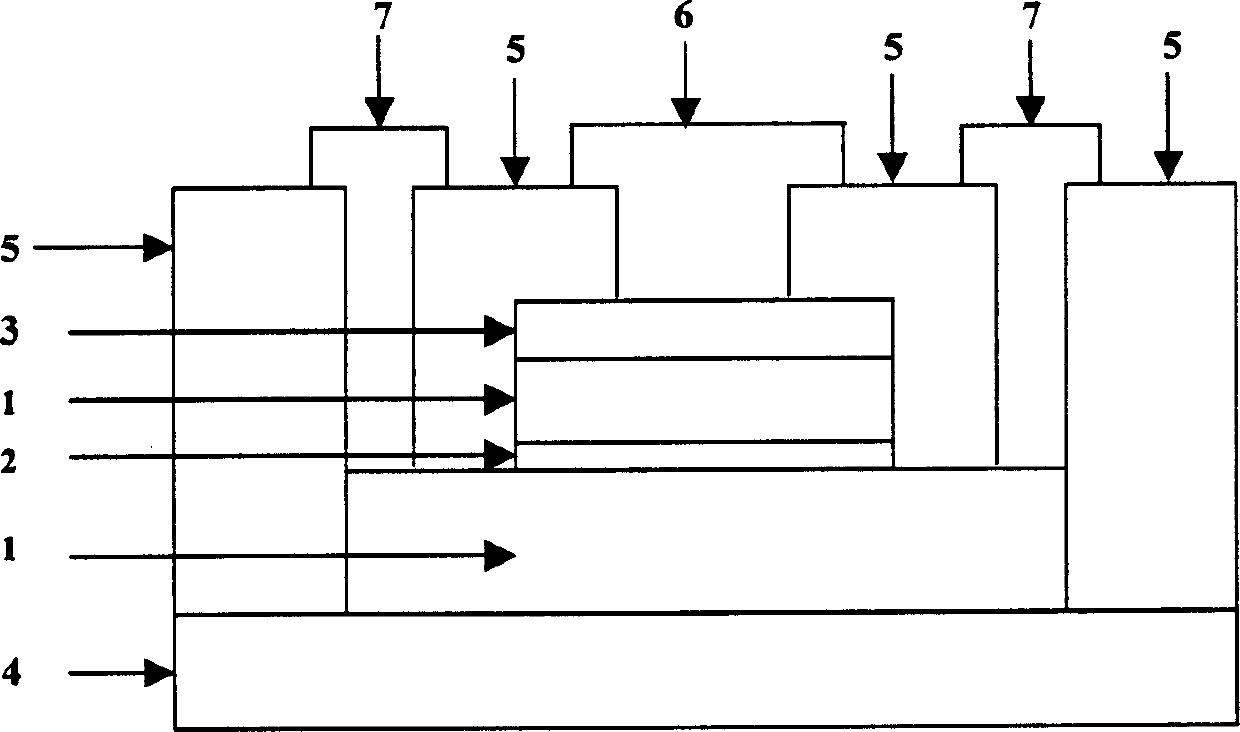

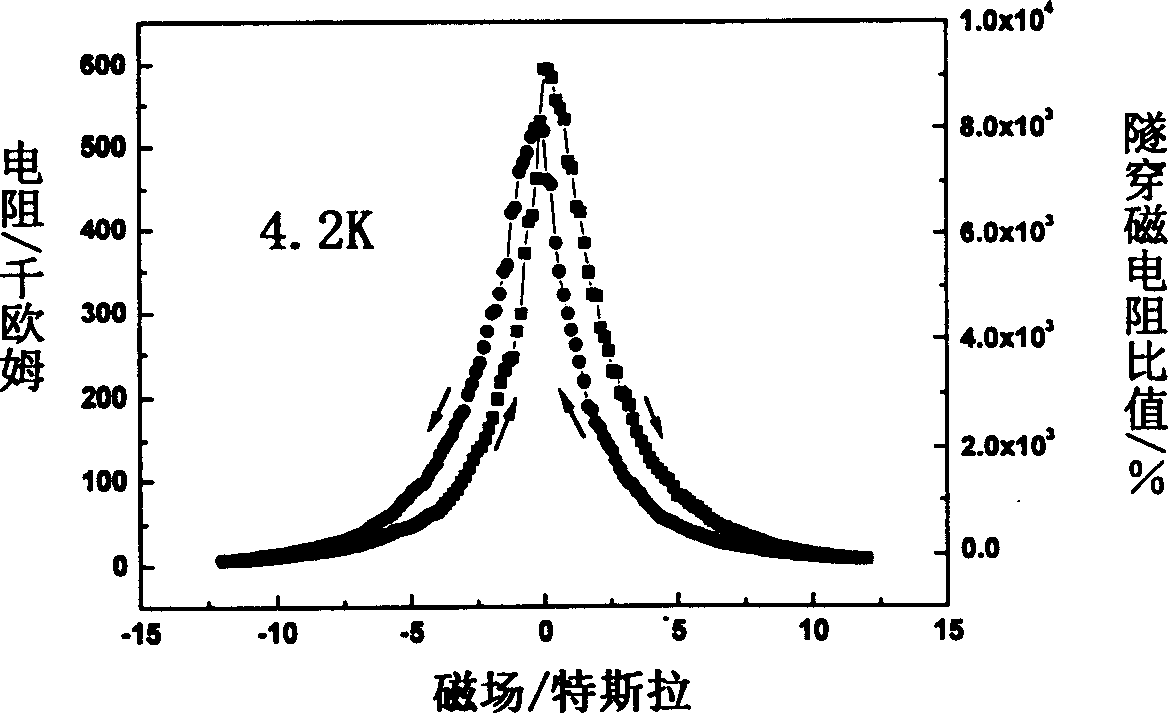

[0022] Select ferromagnetic metal oxide La with Sr composition range of 0.161-x Sr x MnO 3 (FM) As a semi-metallic ferromagnetic layer, La with a Sr composition range of 01-y Sr y MnO 3 (I) as an insulator barrier layer. The method of magnetron sputtering chemical reaction deposition and heat treatment in (001) oriented SrTiO 3 A series of perovskite semimetal composite four-layer films modulated by the strontium composition of the present invention were prepared on the single crystal substrate—La 1-x Sr x MnO 3 (FM1) / La 1-y Sr y MnO 3 (I) / La 1-x Sr x MnO 3 (FM2) (wherein, 0.161-x Sr x MnO 3 (FM1) / La 1-y Sr y MnO 3 (I) / La 1-x Sr x MnO 3 (FM2), and using the same method of preparing the device to prepare a four-layer core structure as AFM / La 1-x Sr x MnO 3 (FM1) / La 1-y Sr y MnO 3 (I) / La 1-x Sr x MnO 3 (FM2) (wherein, 0.16<x<1.0, 0<y<0.16) single barrier composite magnetic tunnel junction. Its composition and properties are listed in Table 1.

[002...

Embodiment 13~24

[0027] Same as Examples 1-12, select ferromagnetic metal oxide La with Sr composition range of 0.161-x Sr x MnO 3 (FM) As a semi-metallic ferromagnetic layer, La with a Sr composition range of 01-y Sr y MnO 3 (I) as an insulator barrier layer. And a series of perovskite semimetal composite seven-layer films modulated by the strontium composition of the present invention can be prepared by using the same method for preparing devices——AFM1 / La with the same material composition strontium 1-x Sr x MnO 3 (FM1) / La 1-y Sr y MnO 3 (I1) / La 1-x Sr x MnO 3 (FM2) / La 1-y Sr y MnO 3 (I2) / La 1-x Sr x mn 3 (FM3) / AFM2 (wherein, 0.16<x<1.0, 0<y<0.16) is a perovskite oxide double-barrier composite magnetic tunnel junction with a core structure. Its composition and properties are listed in Table 2.

[0028] In this double-barrier composite magnetic tunnel junction, the first and second antiferromagnetic pinning layers (AFM1 and AFM2) have a pinning effect; the magnetization dire...

Embodiment 25~33

[0032] Similar to Examples 1-12, the ferromagnetic metal oxide La with a Ca composition range of 0.181-x Ca x MnO 3 As a half-metal ferromagnetic layer (FM), choose La with a Ca composition range of 01-y Ca y MnO 3 As an insulator barrier layer (I); and using the preparation method of the composite multilayer film device in Examples 1 to 12, a series of calcium component-modulated perovskite semimetal composite four-layer films of the present invention—with the same The four-layer core structure of the composite multilayer film with a material composition of calcium is La 1-x Ca x MnO 3 (FM1) / La 1-y Ca y MnO 3 (I) / La 1-x Cax MnO 3 (FM2) / AFM (wherein, 0.181-x Ca x MnO 3 (FM1) / La 1-y Ca y MnO 3 (I) / La 1-x Ca x MnO 3 (FM2) single-barrier composite magnetic tunnel junction. Its composition and properties are listed in Table 3.

[0033] Reality

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com