Planet differential actuator

A starter and differential technology, applied in the field of starters, can solve the problems such as the inability to ensure the reliable operation of the mechanism, the thin floating key control lever, and the inability to guarantee parallel lifting, etc., to achieve convenient daily maintenance work, no impact movement parameter change, lubrication and good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

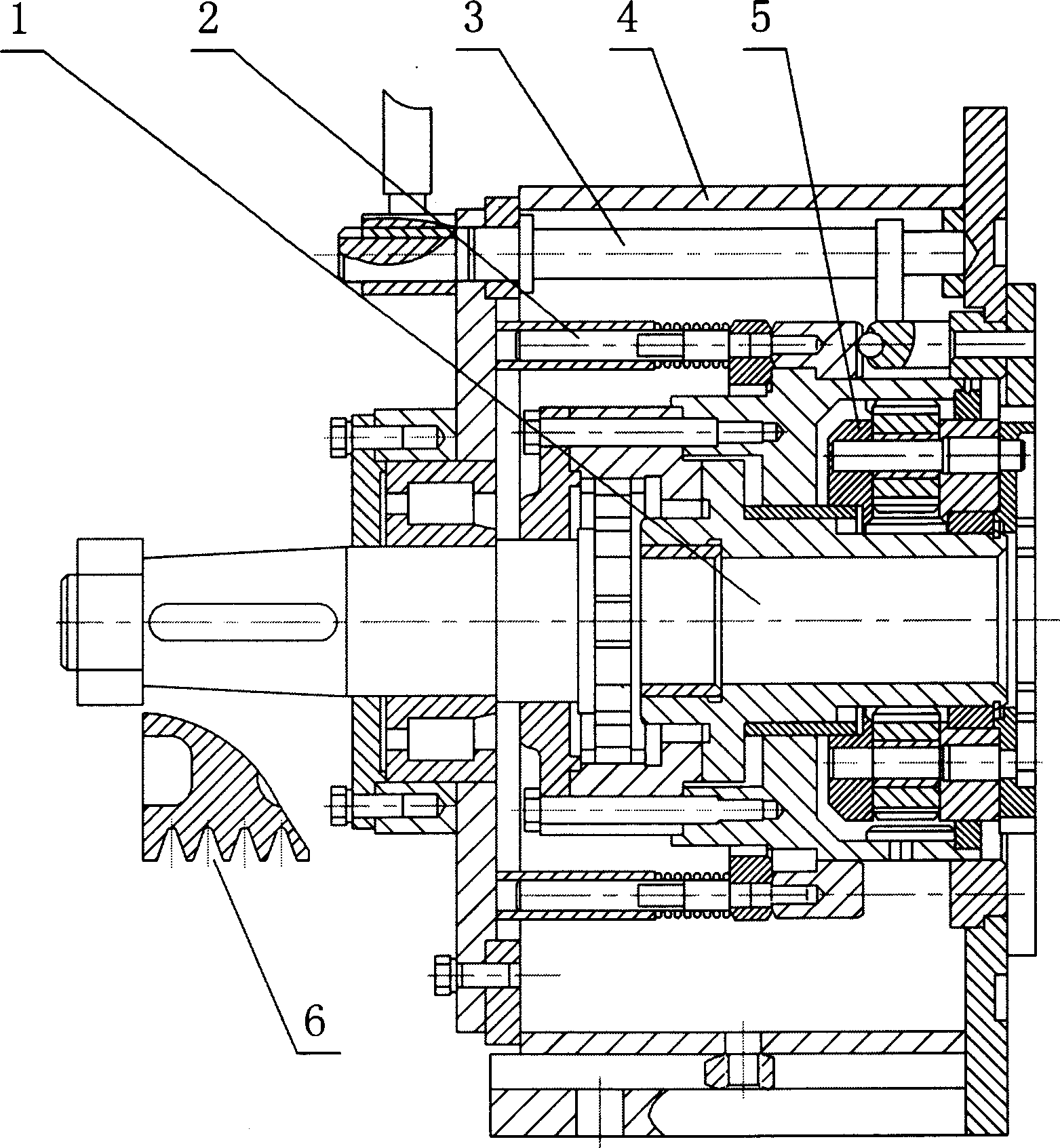

[0047] Such as figure 1 As shown, the planetary differential starter of the present invention includes an output shaft 11, a pulley 6 mounted on the output shaft, a casing assembly 4, and a planetary mechanism 5, which are characterized in that they are arranged in the casing assembly 4 The transmission mechanism 1, the planetary mechanism 5 connected with the transmission mechanism 1, the clutch mechanism 2, and the operation control mechanism 3 connected with the clutch mechanism 2 are composed.

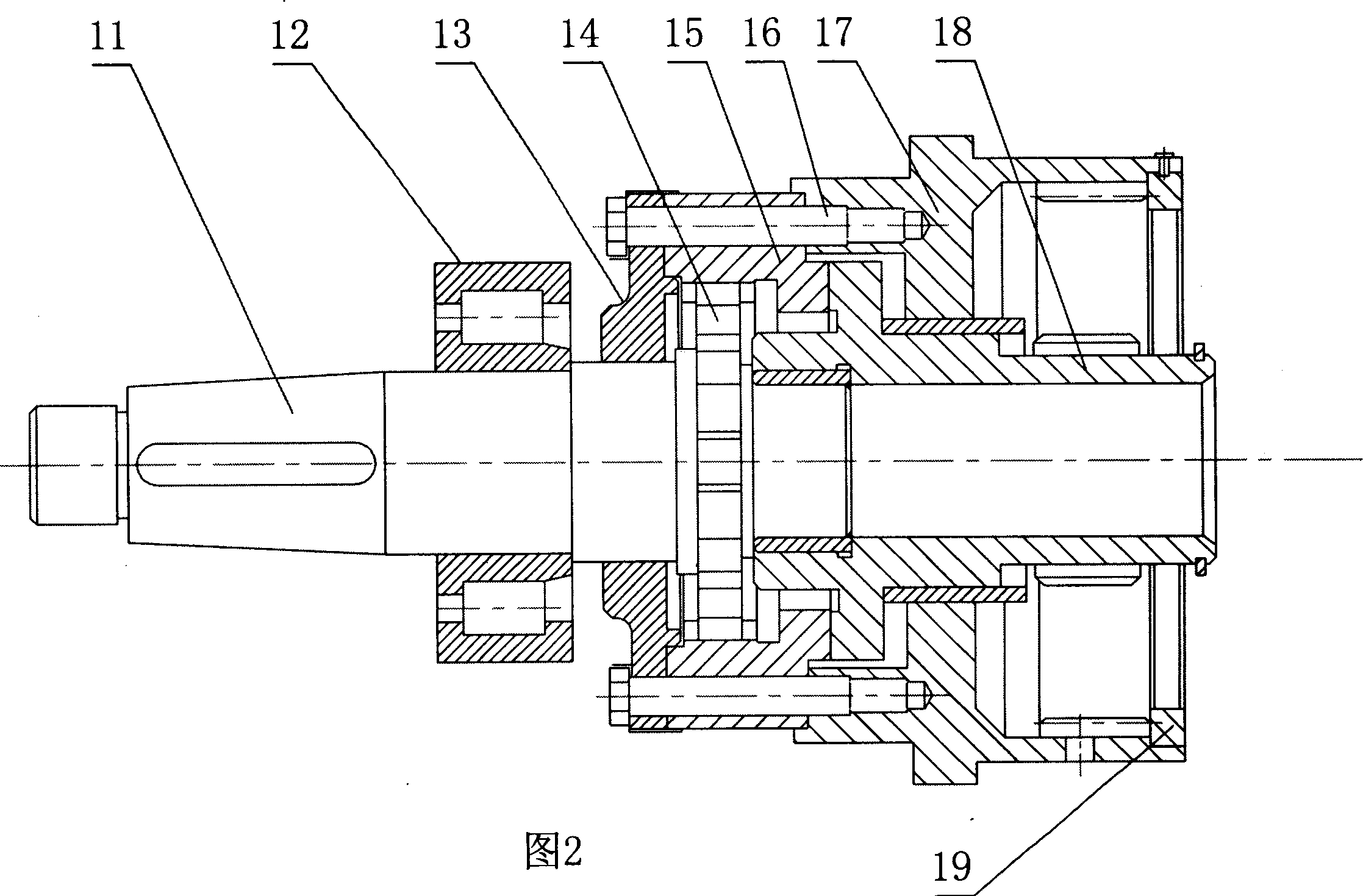

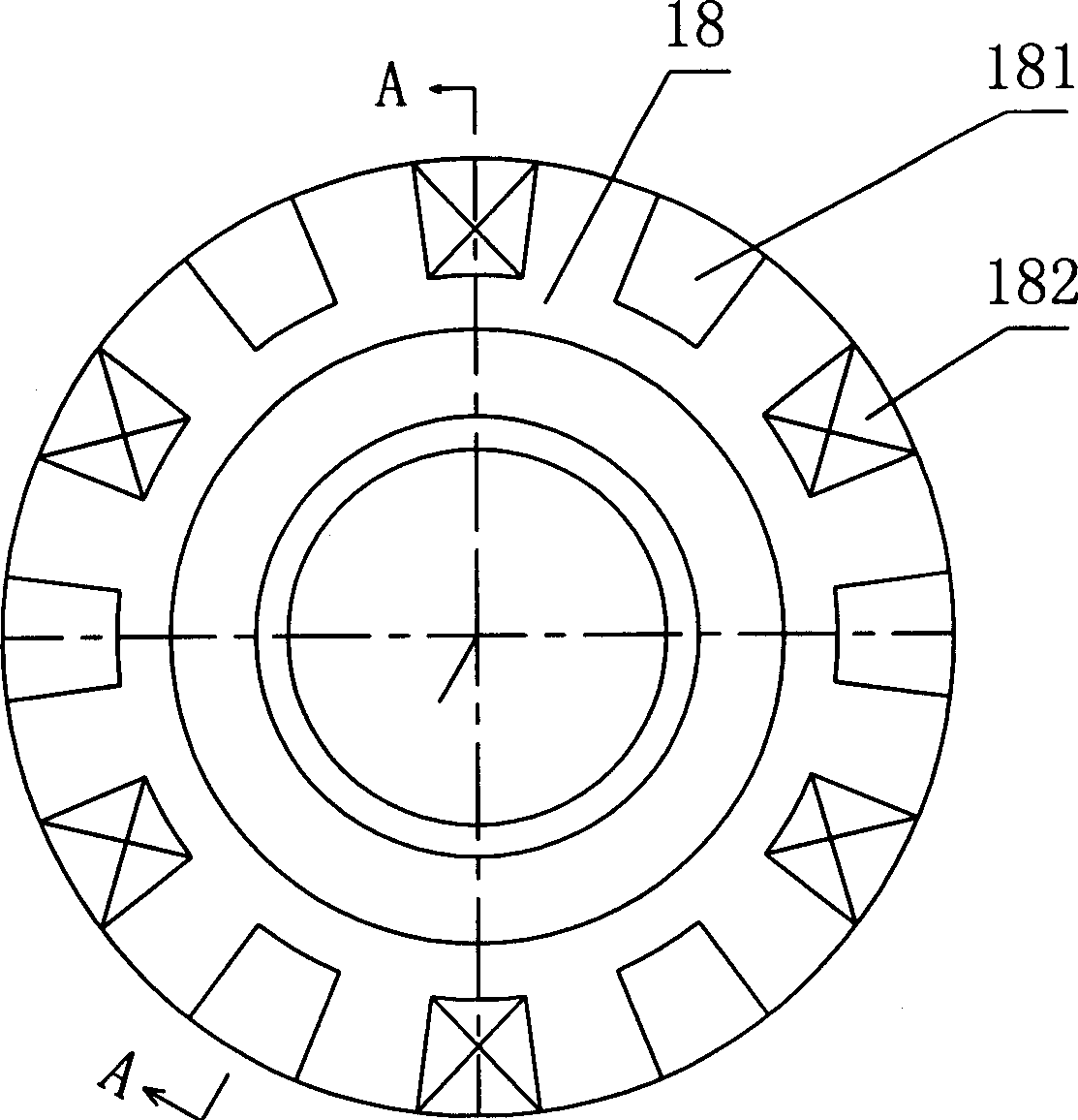

[0048]As shown in Figure 2, the transmission mechanism 1 includes a gear sleeve 18 installed in the box assembly 4 for being connected with the output shaft of the motor, and the output shaft 11 installed at the front end of the gear sleeve 18 is mounted on the The bearing 12 on the output shaft 11, the sliding support seat 13 on the right sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com