Vacuum treatment transformer oil and mutual inductor pressure immersion oil system

A technology of transformer oil and vacuum treatment, which is applied in transformer/inductor parts, inductance/transformer/magnet manufacturing, electrical components, etc., which can solve the problems of low work efficiency, incomplete oil filling and impregnation of products, etc., to reduce labor intensity, The effect of stable treatment quality and improved pressure resistance level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

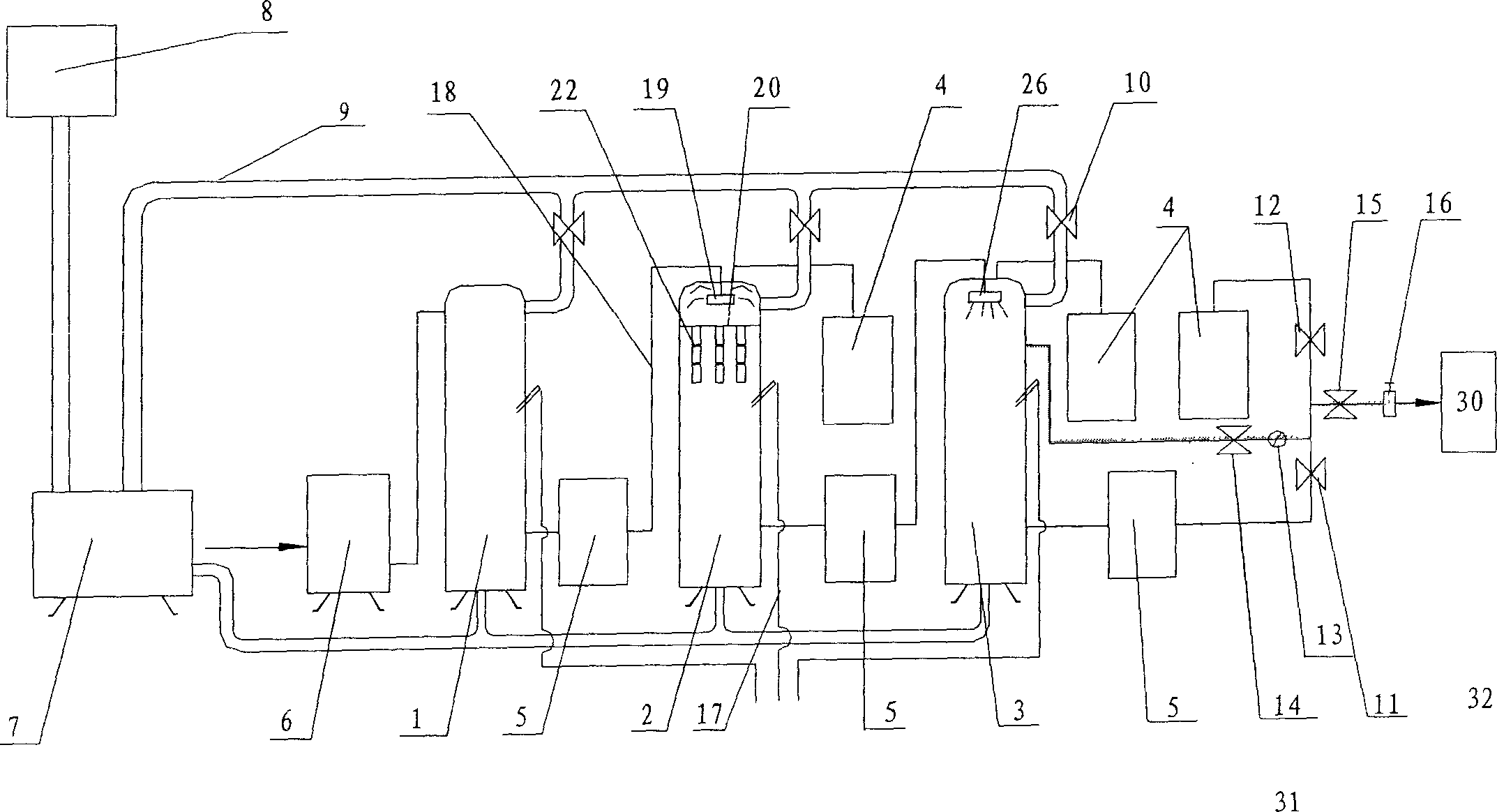

[0015] The vacuum treatment transformer oil and transformer pressure immersion oil system of the invention consists of a sedimentation tank 1, a degassing tank 2, a pressure immersion tank 3, a vacuum pump 4, a vortex pump 5, an oil filter 6, a water heater 7, and a water tower 8 , water pipeline 9, and oil pipeline 18 form two parts of a closed-loop waterway and an open-loop oilway; in the closed-loop waterway, the water tower 8 is connected to one end of the water heater 7, the water tower 8 is located above the water heater 7, and the other end of the water heater 7 It is connected with sedimentation tank 1, degassing tank 2, and pressure immersion tank 3, and the outlet pipes of the three tanks are connected with water heater 7, which form a network pipe circuit; the open-loop oil route is oil filter 6 through oil pipeline 18 and sediment The upper end of the tank 1 is connected, the lower end of the sedimentation tank 1 is connected with the upper end of the degassing tank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com