High energy full-wave band infrared radiation heater

An infrared radiation, full-band technology, applied in the direction of heating element materials, etc., can solve the problems of small radiation surface area of quartz heating tube, high operating cost, easy oxidation of metal materials, etc., to achieve the effect of short heating start time, safe and reliable insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

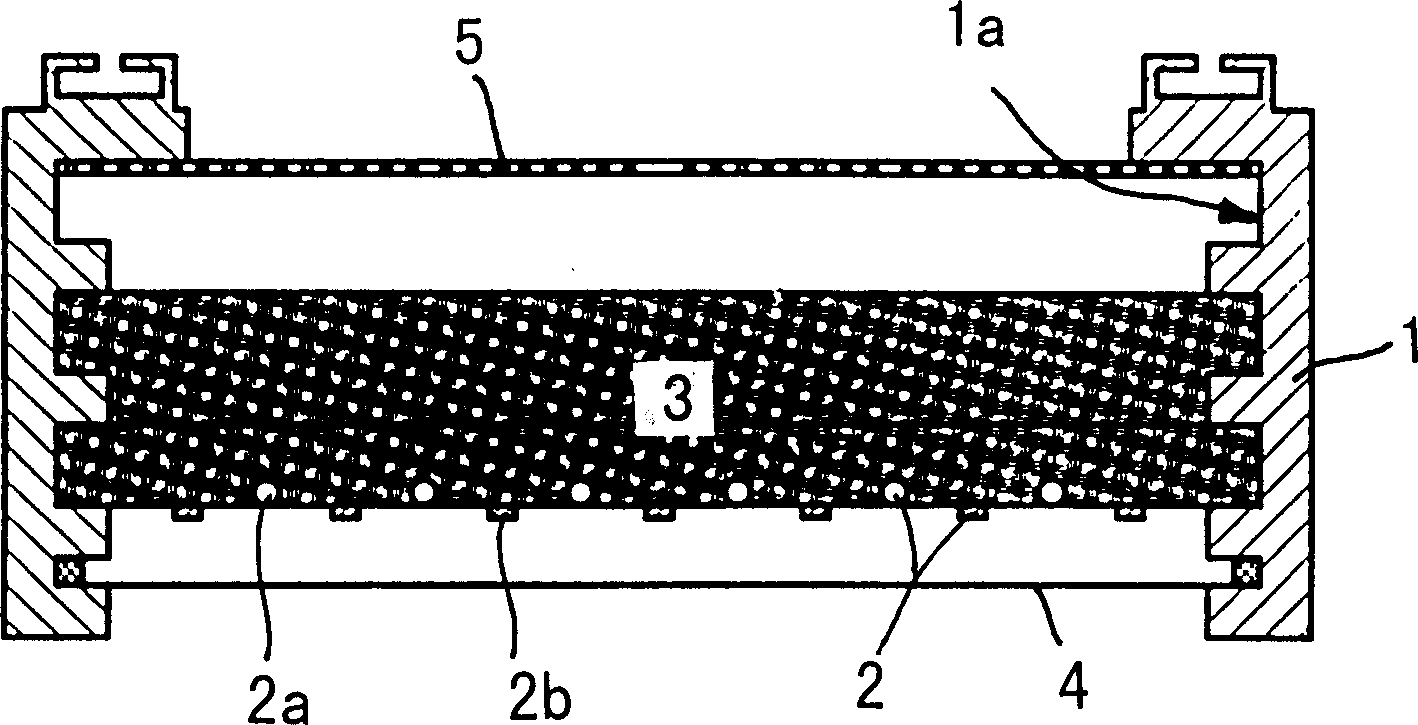

[0009] figure 1 The shown high-energy full-band infrared radiant heater is used in the non-contact coating coating curing furnace for small metal workpieces. The surface of metal decorative small fasteners is dyed after nylon coating, and the high-energy full-band infrared radiant heater is used to achieve coating heating and plasticization. The small workpiece is a galvanized stamping part, the plate thickness is 0.6mm, the workpiece size is 8-shaped, and the size of the workpiece It is 200×100×100mm(max), and the weight of the workpiece is 300mg / piece. The powder coating is nylon 11, the melting point is 187±4℃, the particle size is 200 mesh, and it is white. Using the heater of the present invention, the electric power is 6KW, the furnace body length is 1.0 m, and the curing time is 0.5 minutes; while the original far-infrared opal quartz heating tube is used, the electric power is 24KW, the furnace body length is 6 meters, and the curing time is 6 minutes.

[0010] Positive e...

Embodiment 2

[0012] This heater is applied to the drying tunnel of the silicone-rich zinc-rich paint for automobile brake discs. The surface of automobile brake disc (casting) is sprayed with organic silicon zinc-rich coating to meet the requirements of high temperature resistance and rust prevention. Use this heater to realize coating curing.

[0013] Workpiece: Automobile brake disc, diameter 350mm, paint is organic silicon zinc-rich paint, the thickness of the coating is 20-30 microns (can be divided into two coatings),

[0014] Coating process: After shot blasting, the surface of the workpiece is dehydrated and dried by phosphating treatment, sprayed with clean compressed air (P0.4~0.5MPa), curing temperature is 160~180℃, and the process requires curing time of 30~40min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Insulation properties | aaaaa | aaaaa |

| Heat resistant | aaaaa | aaaaa |

| Heating power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com