Assemblied anthropomorphic manipulator based on imbedded shape memory alloy electric machine

A memory alloy, embedded technology, used in manipulators, manufacturing tools, chucks, etc., can solve problems such as limited clamping capacity, and achieve the effects of low manufacturing cost, light weight and flexible control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing and example the present invention is described in further detail.

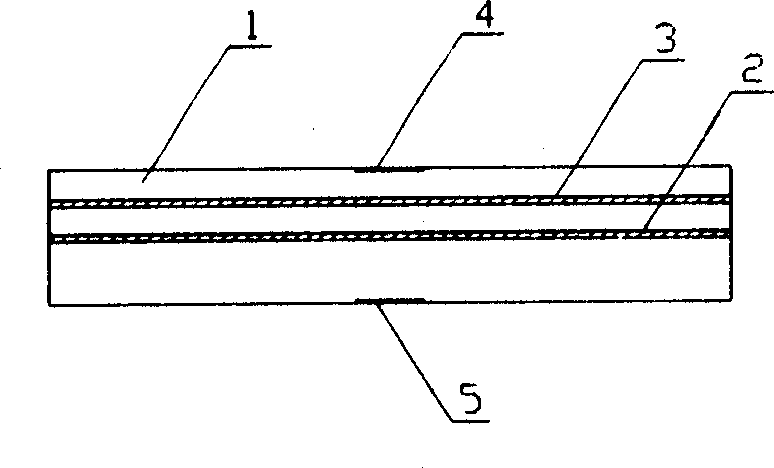

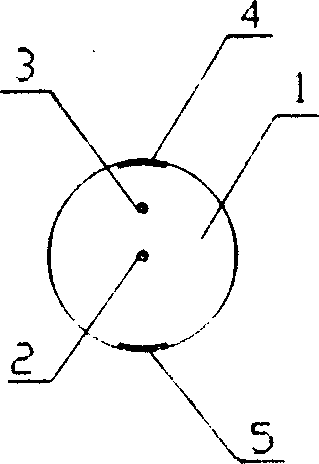

[0013] Such as figure 1 and figure 2 As shown, the embedded shape memory alloy motor (ESMAA) includes: a silicone rubber cylinder 1, a "U" shape memory shape memory alloy (SMA) wire 2, a linear shape memory SMA wire 3, and symmetrically distributed curvature sensors 4 and 5 . The embedding position of the "U" shape memory SMA wire 2 coincides with the central axis of the silicone rubber cylinder 1, the linear memory SMA wire 3 is embedded eccentrically parallel to the central axis of the silicone rubber cylinder 1, and the curvature sensors 4 and 5 are symmetrically distributed along the bending direction. The middle surface of the silicone rubber cylinder 1 . The "U" shape memory SMA wire 2 has a recovery function, and the straight memory SMA wire 3 has a recovery function, so that this ESMAA has a plane bending function.

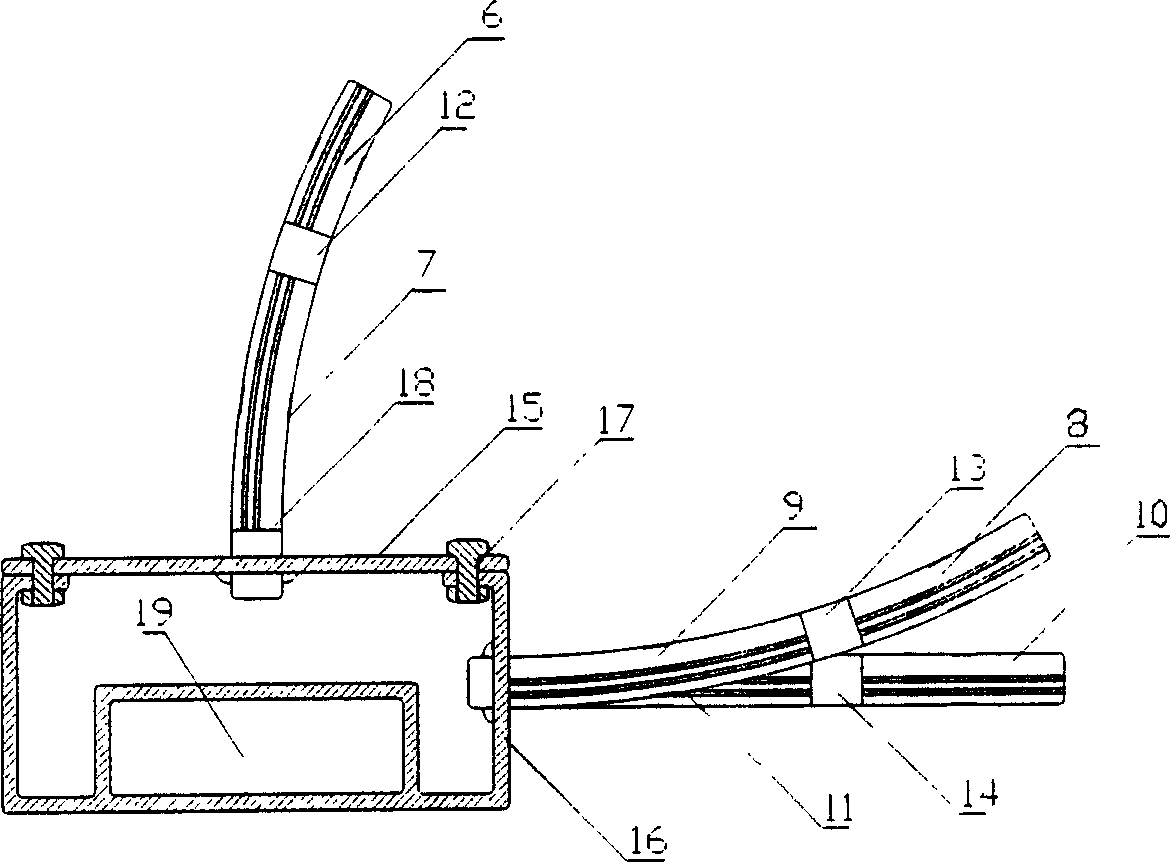

[0014] Such as image 3 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com