Continously variable valve timing valve actuating mechanism piston IC engine

A valve train, valve timing technology, applied in the direction of internal combustion piston engine, machine/engine, mechanical equipment, etc., can solve the problems of inability to control the duration of intake and exhaust valves, limit the effective power and thermal efficiency of internal combustion engines, and achieve exhaust gas. The effect of rapid, clean exhaust and bottom removal, and rapid combustion

Inactive Publication Date: 2006-09-13

王雪松

View PDF0 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] At present, the continuously variable valve timing mechanism of the known piston internal combustion engine can only control the opening and closing time of the intake and exhaust valves by changing the timing of the intake and exhaust valve camshafts, but cannot control the opening and closing of the intake and exhaust valves. duration of

This limits the further improvement of the effective power and thermal efficiency of the internal combustion engine, the reduction of fuel consumption and the improvement of pollutant emission performance through the continuously variable valve timing system

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

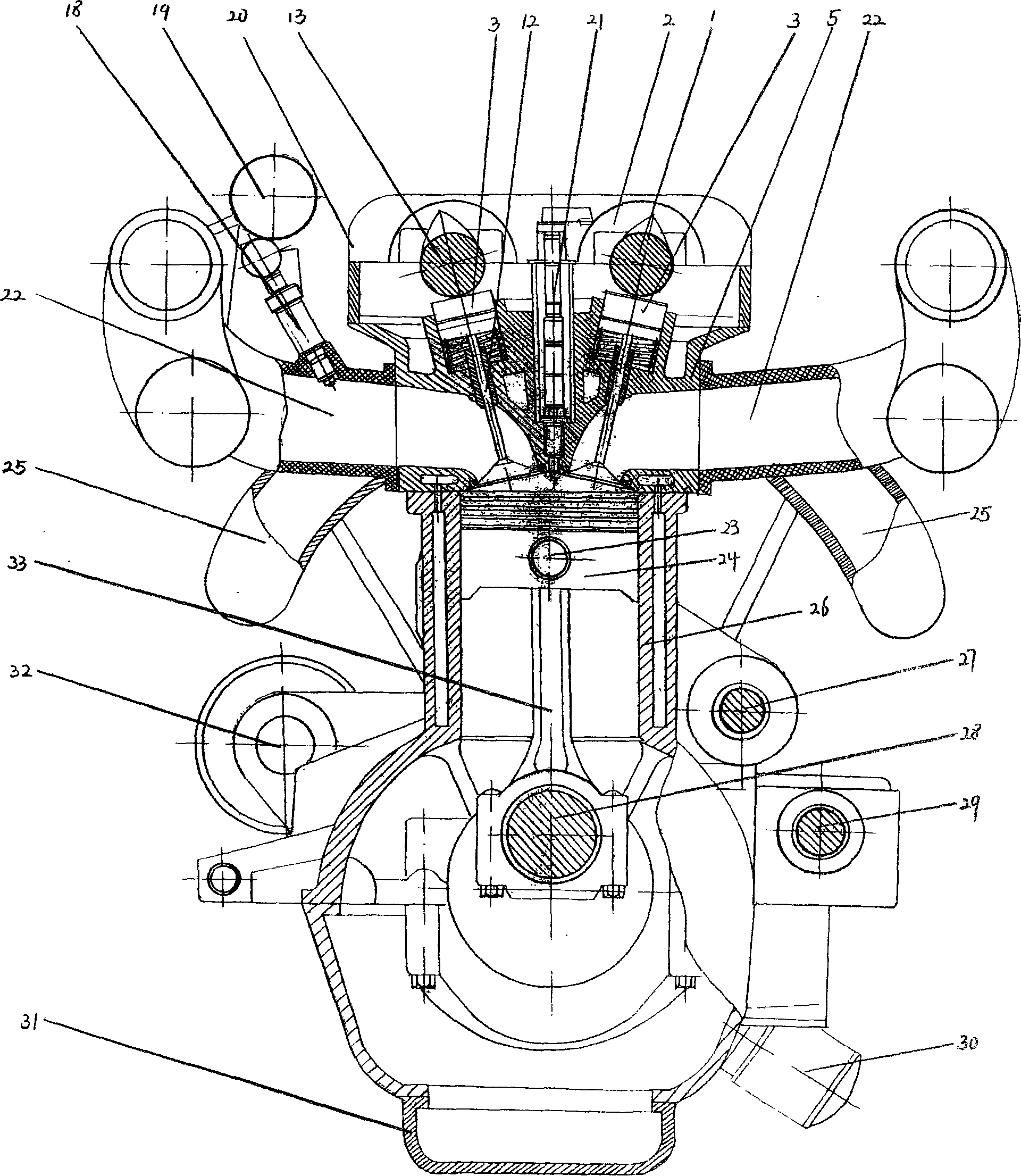

[0051] exist Figure 5 Among them, the installation hole (39) on the bottom surface of the cylinder head (5), the lubricating oil passage (41), the cooling liquid passage (42), the combustion chamber (40) and the main intake valve (4) in the combustion chamber (40) , auxiliary intake valve (12), main exhaust valve (16) and auxiliary exhaust valve (15) and spark plug (21).

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

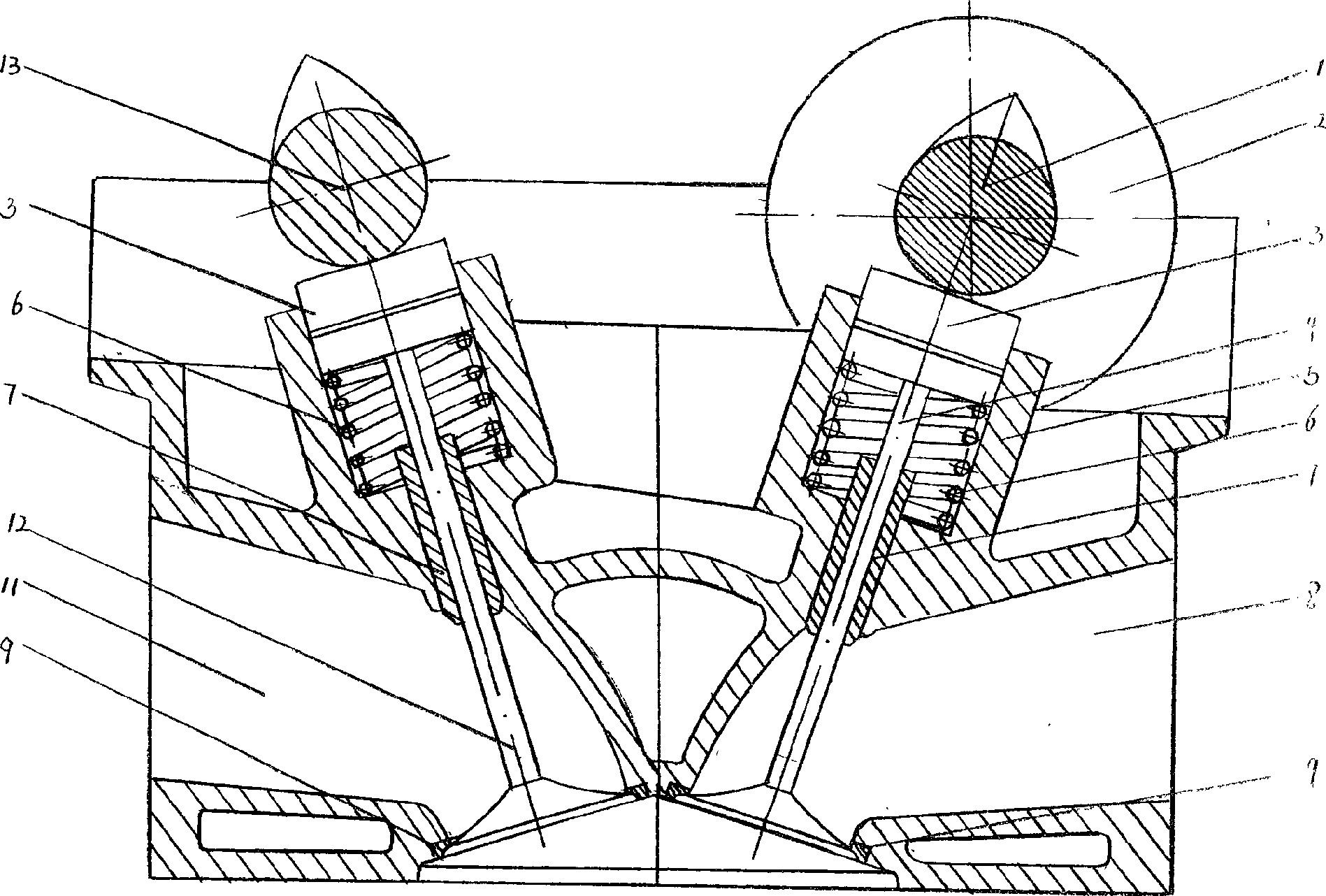

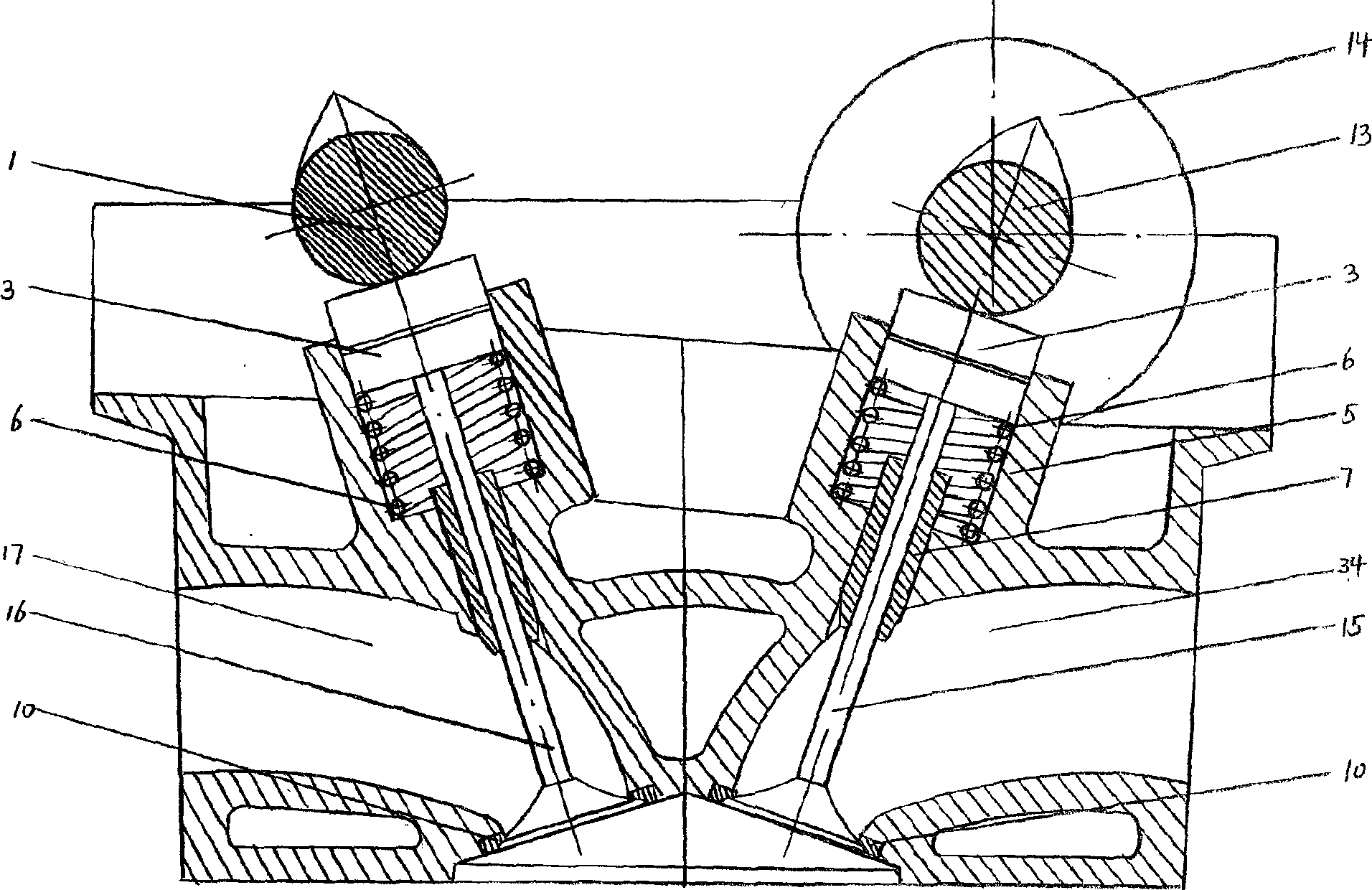

The invention is a piston internal-combustion engine with continuously variable valve timing mechanism, characterized by that: it adopts a structure of main and auxiliary gas inlet and outlet cam shafts, where each cam shaft can control corresponding gas inlet and outlet valves, the main cam shaft controls ON / OFF of main gas inlet and outlet valves, and the auxiliary one controls ON / OFF of auxiliary gas inlet and outlet valves. And it can control ON / OFF time and ON-to-OFF time of the gas inlet and outlet valves by continuously varying valve timing of the gas inlet and outlet cam shafts, thus further improving effective power and thermal efficiency of internal-combustion engine and reducing fuel oil consumption and pollutant discharge.

Description

Technical field [0001] A continuously variable valve timing valve mechanism piston internal combustion engine, especially a continuously variable valve timing arrangement that controls the opening and closing and duration of the intake and exhaust valves by continuously changing the phase of the intake and exhaust camshafts Pneumatic piston internal combustion engine. Background technique [0002] At present, the continuously variable valve timing mechanism of the known piston internal combustion engine can only control the opening and closing time of the intake and exhaust valves by changing the timing of the intake and exhaust valve camshafts, but cannot control the intake and exhaust valves from opening to closing. duration. Thereby limiting the further improvement of the effective power and thermal efficiency of the internal combustion engine through the continuously variable valve timing system, the reduction of fuel consumption and the improvement of pollutant emissio...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F01L1/34F02D13/02

CPCY02T10/18Y02T10/12

Inventor 王雪松

Owner 王雪松

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com