Fuel apparatus with pressurized fuel

A pressurized fuel and fuel technology, applied in lighting and heating equipment, gas fuel burners, fuel cells, etc., can solve the problems of high structure and economic costs, and achieve the effects of reducing economic costs, small structure size, and good efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

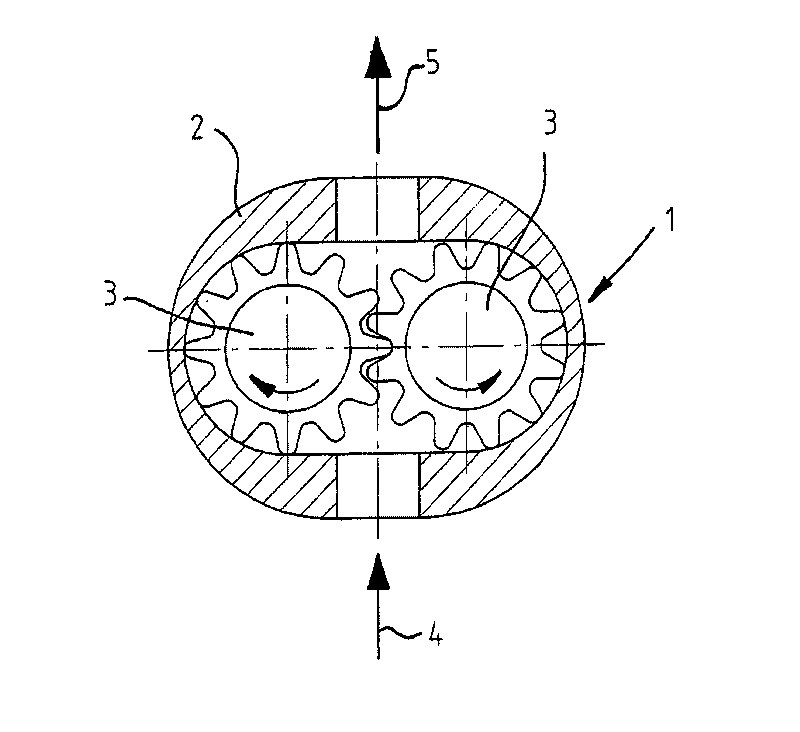

[0032] exist figure 1 A gear mechanism 1 with a housing 2 and two meshing gears 3 is schematically shown in FIG. The gear mechanism 1 has an inlet 4 on the high-pressure side and an outlet 5 on the low-pressure side.

[0033] When fuel or hydrogen flows through the gear mechanism 1 , the gear 3 rotates in the direction of the arrow shown in the drawing.

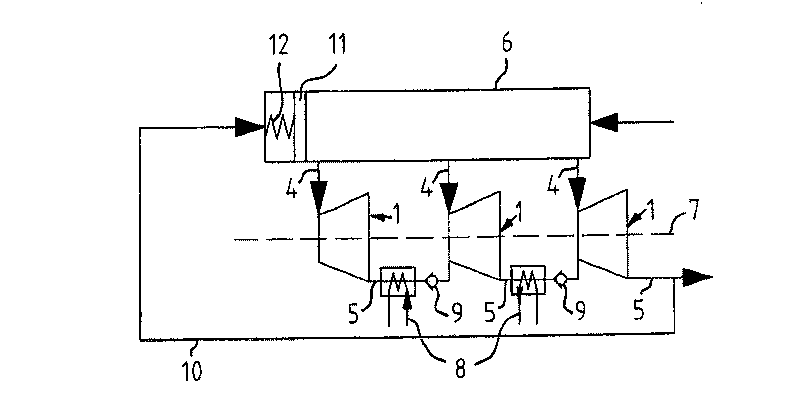

[0034] exist figure 2 Shown in is a schematic representation of a gear mechanism system with multi-stage pressure expansion. The distribution unit 6 here distributes the fuel to, for example, three gear mechanisms 1 arranged on a common transmission shaft 7 . The transmission shaft 7 can be connected to a generator for generating electrical energy, which is not shown in detail.

[0035] A heat exchanger 8 or a heating unit 8 , respectively, can be arranged between the gear mechanism 1 in order to add some heat to the cooled fuel or hydrogen due to the expansion. The cooling of individual components, which are not shown ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com