Fluid colloid crystal and process for producing three-dimensional aligned particle mass thereof

A colloidal crystal, three-dimensional ordering technology, applied in optics, instruments, optical components, etc., can solve problems such as unsatisfactory properties, defects, lack of structural uniformity in ordered structures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

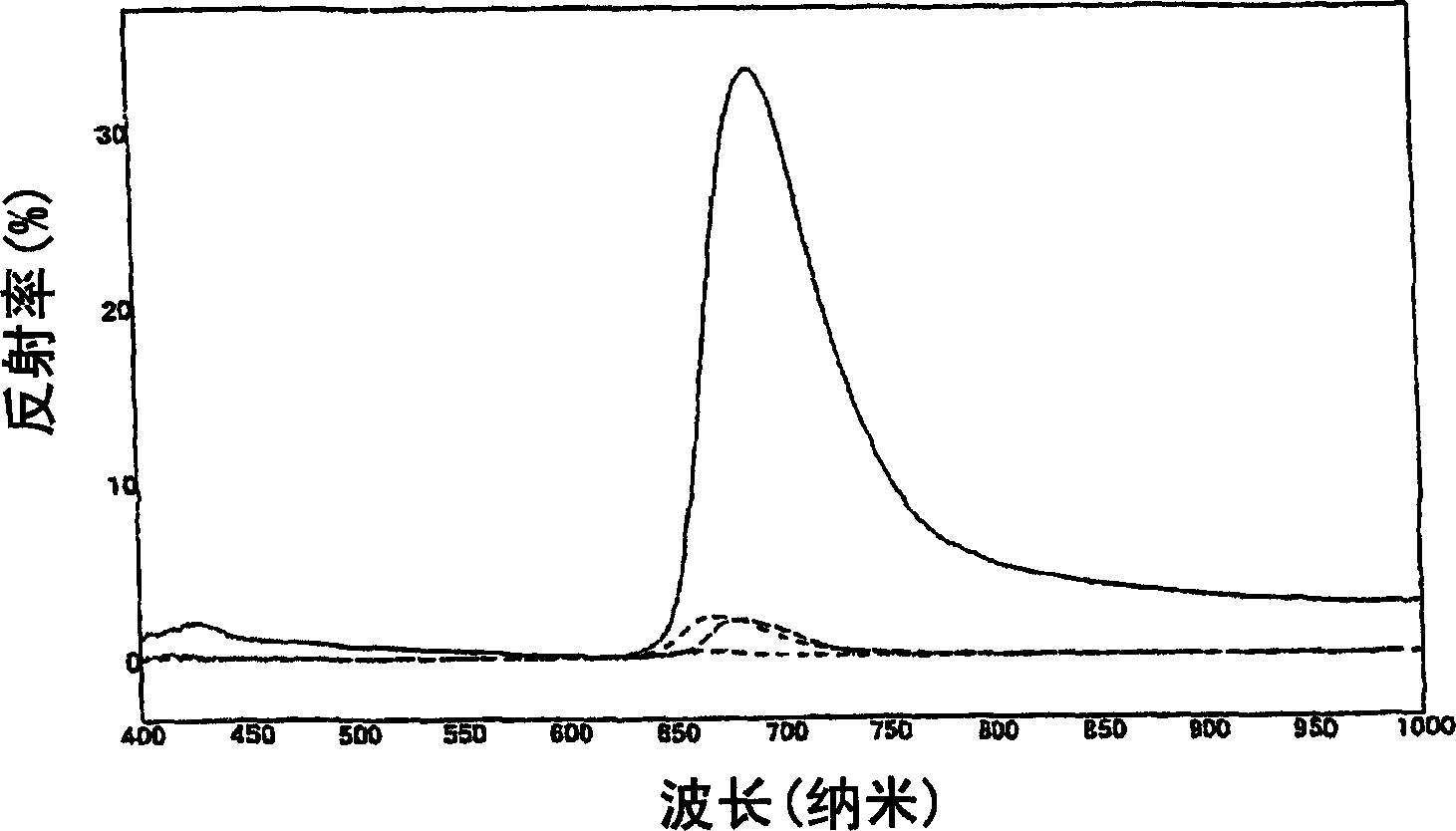

[0202] Impurities such as unreacted monomers and emulsifiers are removed from the suspension (S1), and then the suspension (S1) is subjected to dialysis treatment to reduce its conductivity from the initial 4000 μS / cm to 400 μS / cm. The dialyzed suspension was gradually concentrated to a volume concentration of 36%. At this time, the color of the solid-liquid colloidal dispersion (suspension) visually perceived in the vertical direction is a green spectral diffraction color.

Embodiment 2

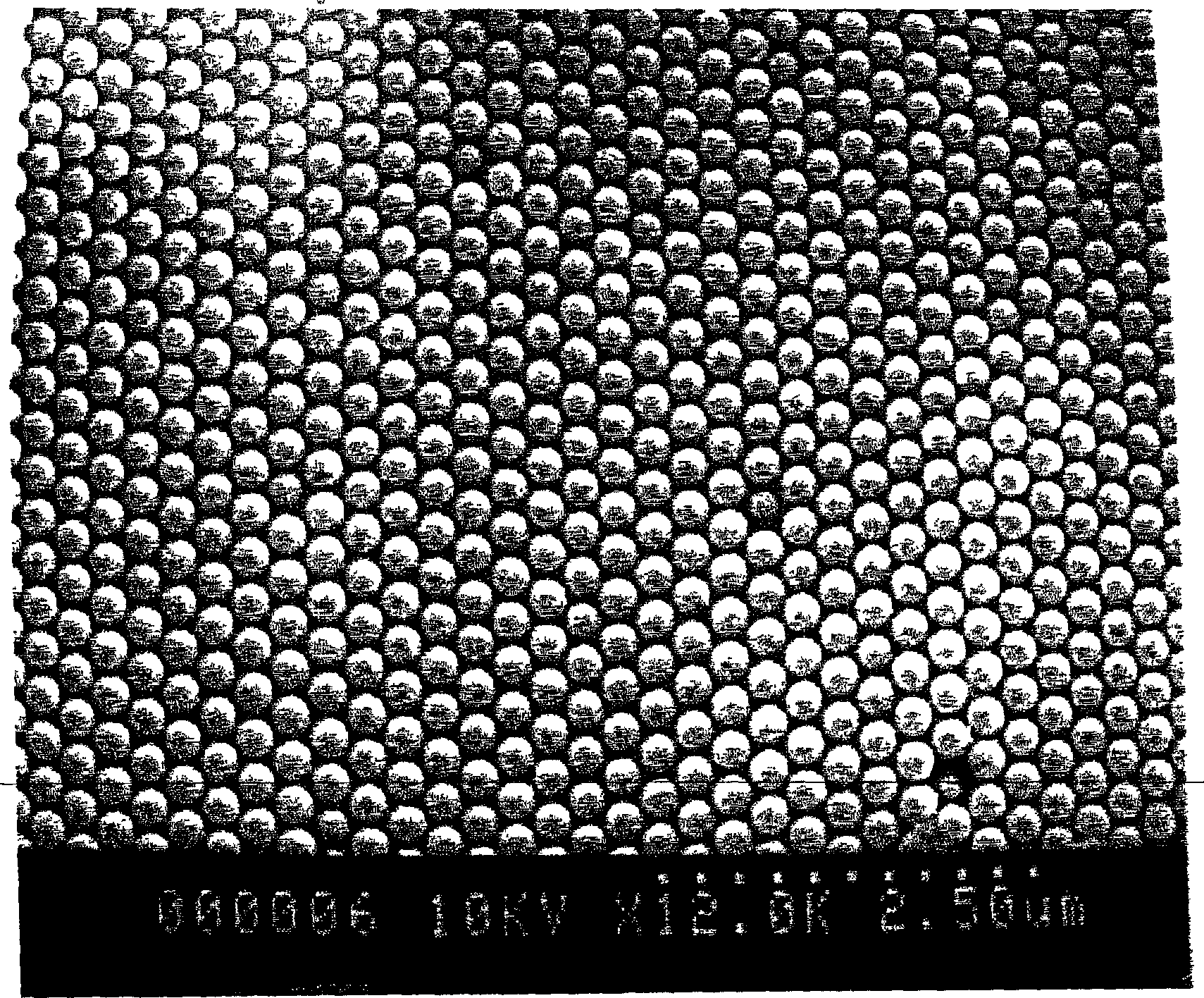

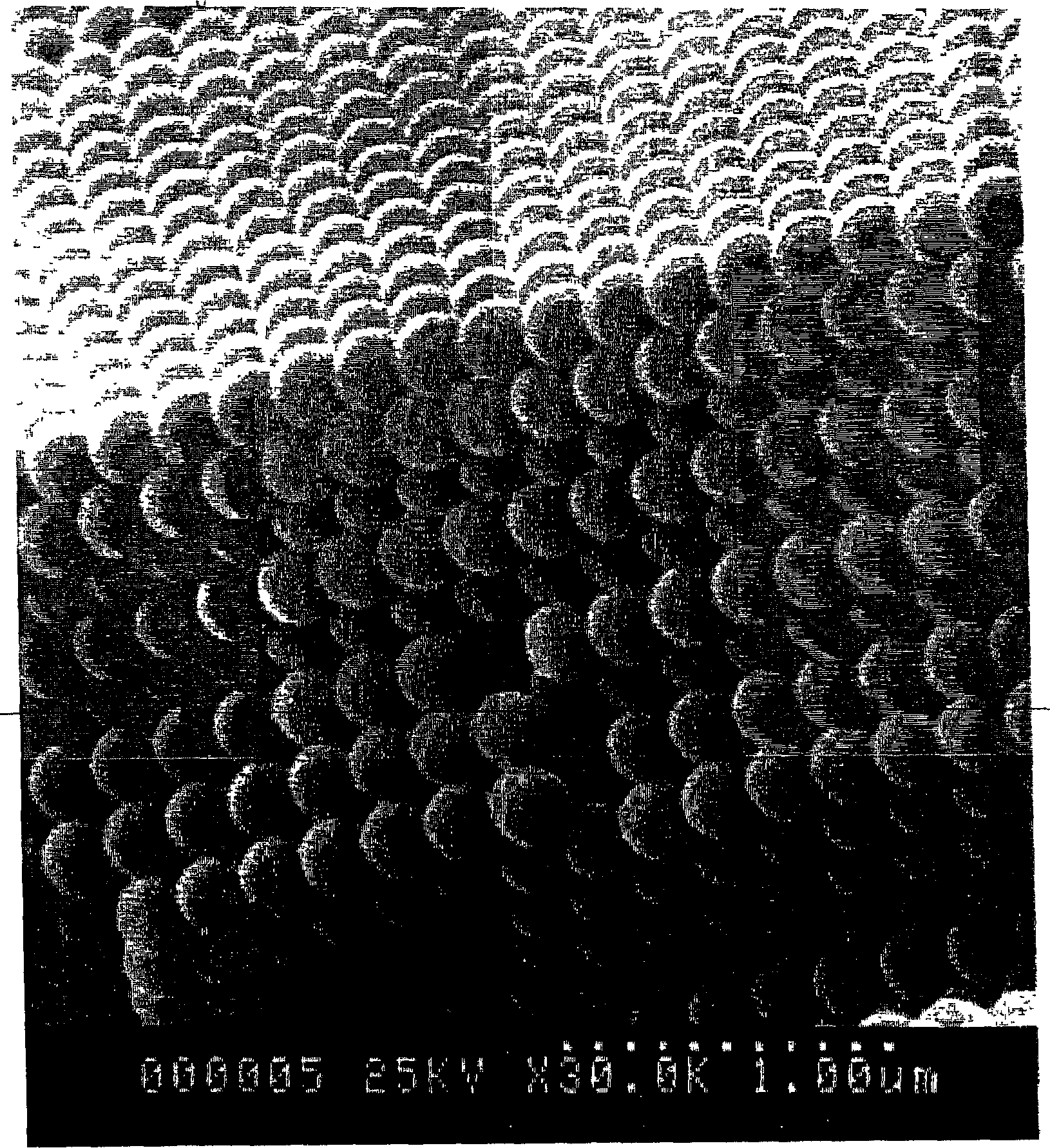

[0204] The MMA of 80 parts by weight and the benzoyl peroxide of 1.0 parts by weight are added in the four-necked flask of 1 liter to form a solution, then the water of 200 parts by weight, the polyoxyethylene polycyclic phenyl ether sulfuric acid of 3.3 parts by weight are added thereto The ester salt emulsifier and 6.5 parts by weight of C.I Sclvent Black 27 black dye were mixed with vigorous stirring. Then 28.6 parts by weight of the suspension (S1) prepared in Reference Example 1 were added to the mixture. The resulting mixture was gently stirred at 50°C for 0.5 hours, and then reacted at 75°C for 1.5 hours to prepare a suspension of polymer particles (S2). In the resulting suspension (S2) black polymer particles were formed which, according to electron microscopy, were monodisperse spherical particles with a volume average diameter of 200 nm. The volume concentration of solids was 21%. Impurities such as unreacted monomers and emulsifiers were removed from the suspensio...

Embodiment 3

[0206] A suspension was prepared by the same method as in Example 2, except that the conductivity was reduced to 100 μS / cm by dialysis. The suspension was gradually concentrated to a volume concentration of 38%. At this time, the color of the solid-liquid colloidal dispersion (suspension) visually perceived in the vertical direction is a red spectral diffraction color.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com