Image recovery and pupil filtering type transverse super-resolution confocal microscopic imaging method and apparatus

A confocal microscopy imaging, pupil filtering technology, applied in microscopes, optics, optical components, etc., can solve problems such as high cost, technology and system complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The image restoration and pupil filter type lateral super-resolution confocal microscopic imaging method and device of the present invention are described in detail in combination with embodiments and accompanying drawings as follows:

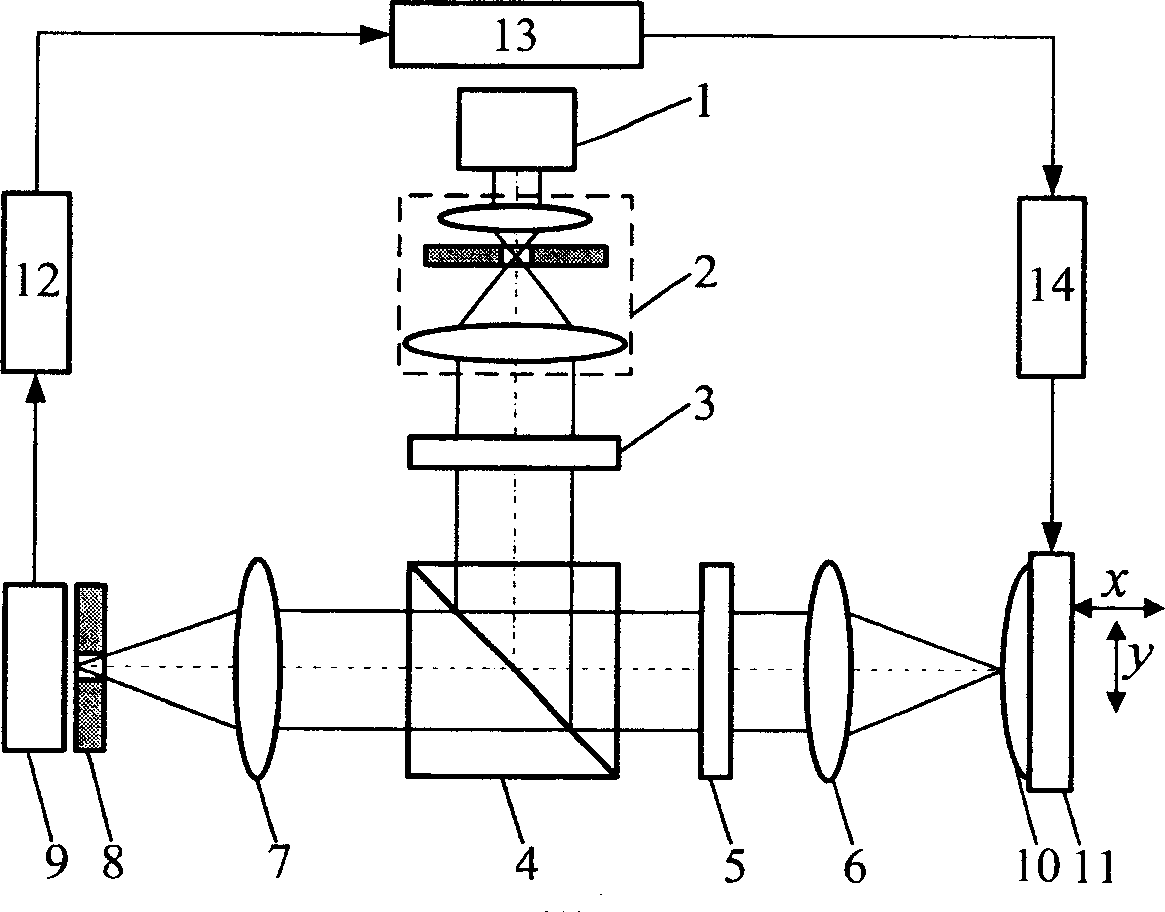

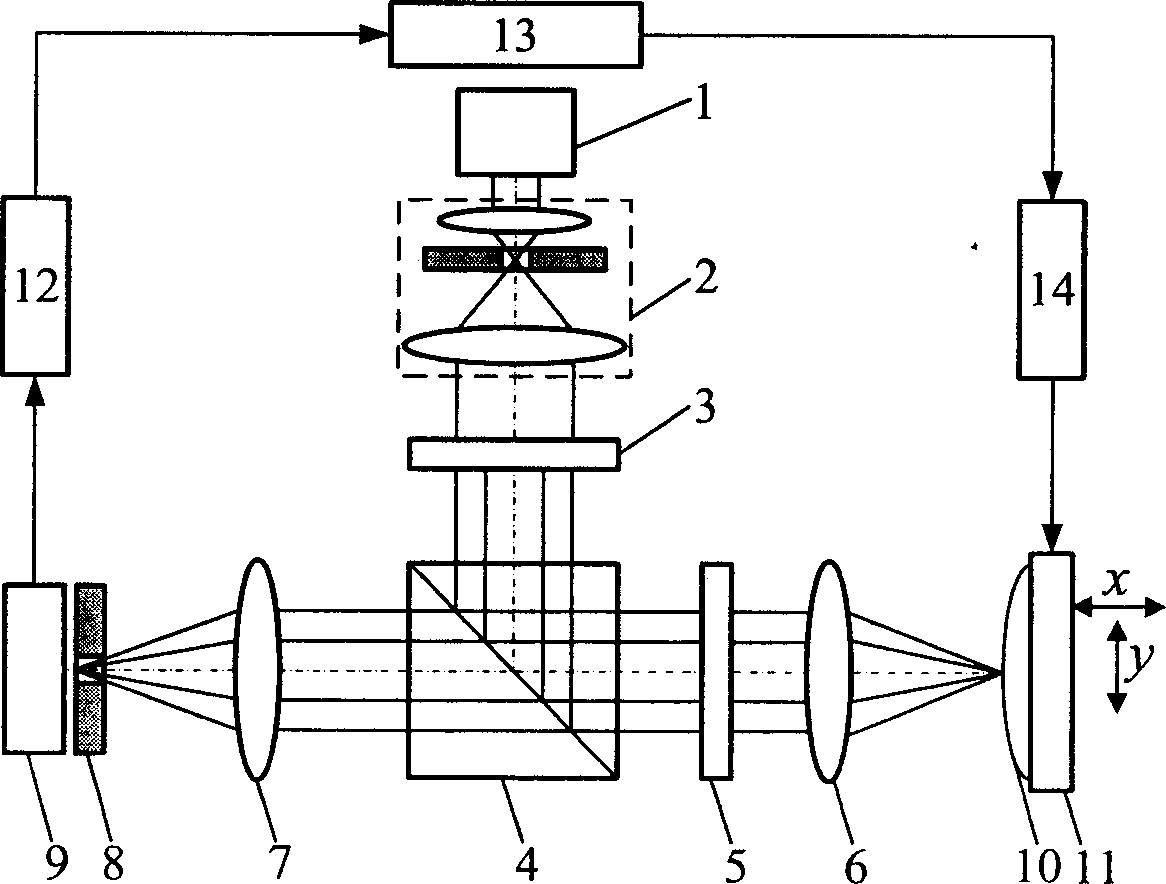

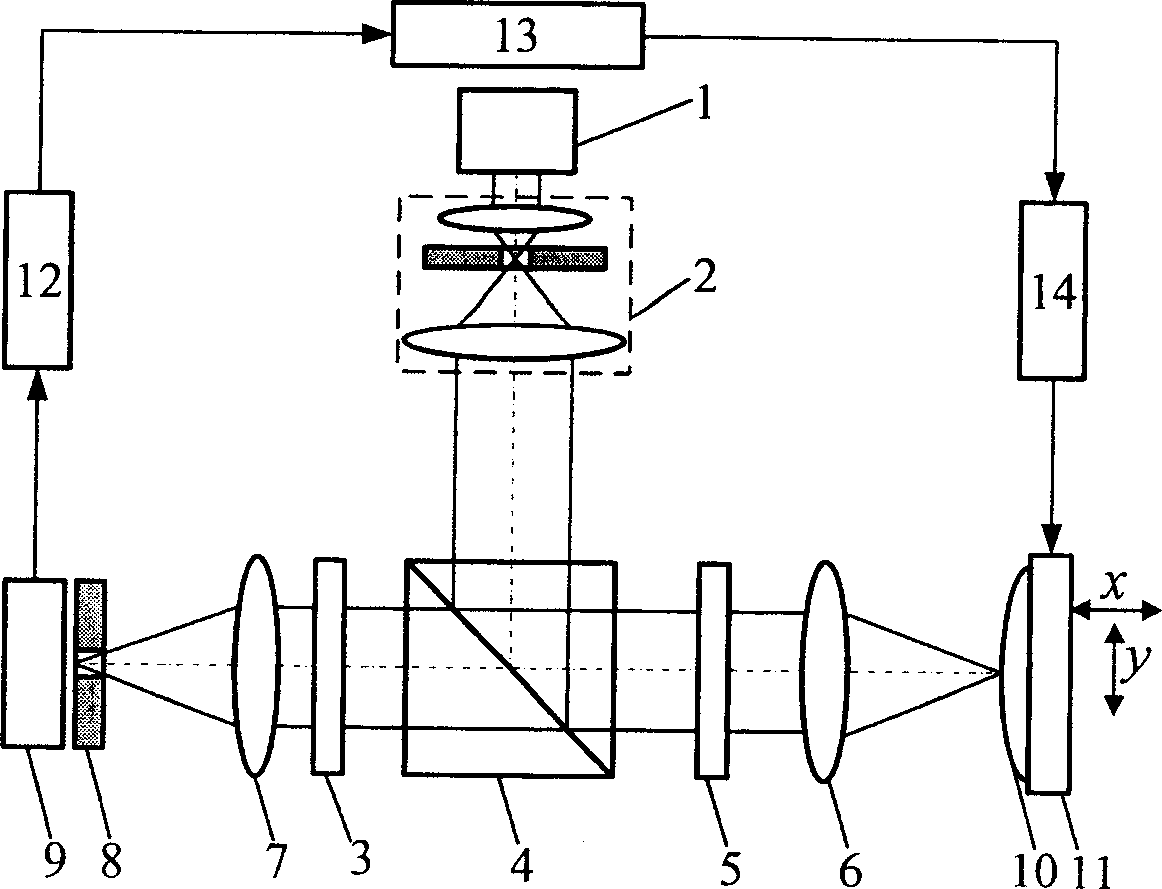

[0048] The system device of Embodiment 1 of the present invention is as figure 2 As shown, it includes a light source 1, a collimating beam expander 2, a pupil filter 3, a polarization beam splitter 4 placed on the light source emitting end in turn, a 1 / 4 wave plate 5 placed on the reflection light path of the polarization beam splitter 4, and a display Micro-objective lens 6, and the condenser lens 7 that is placed on the polarizing beam splitter 4 transmitted light paths and the pinhole 8 that is positioned at the focal point of condenser lens 7, and the CCD detector 9 that is close to the pinhole 8 back, also includes follow CCD detector 9 connected image acquisition card 12, a computer measurement control and image processing system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com